Method for preparing oil and protein by cold pressing and enzymolysis of sesame

A cold-pressed enzyme and sesame technology, which is applied in the direction of fat oil/fat production, fat production, fermentation, etc., to achieve the effects of mild reaction conditions, high product quality and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Screening test of optimal parameters of sesame cold pressing process

[0030] 1 Materials and methods

[0031] 1.1 Materials and reagents

[0032]

[0033] 1.2 Main instruments and equipment

[0034]

[0035] 1.3 Test method

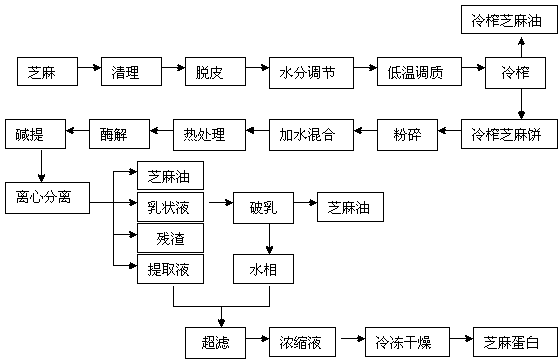

[0036] 1.3.1 Process flow

[0037] Sesame→peeling→low temperature tempering→cold pressing→cold pressing sesame cake→crushing→mixing with water→heat treatment→enzymolysis→enzyme inactivation→alkaline extraction→centrifugal separation→sesame oil

[0038] 1.3.2 Calculation formula

[0039]

[0040] 2 Results and discussion

[0041] 2.1 Level coding table of experimental factors

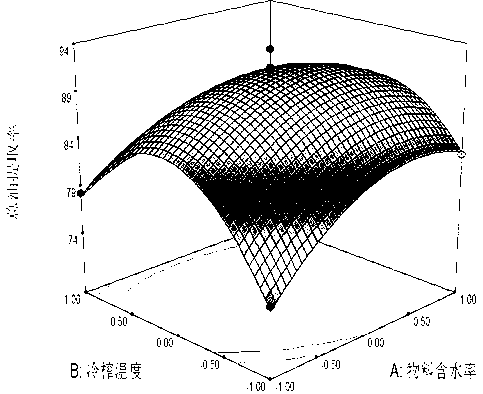

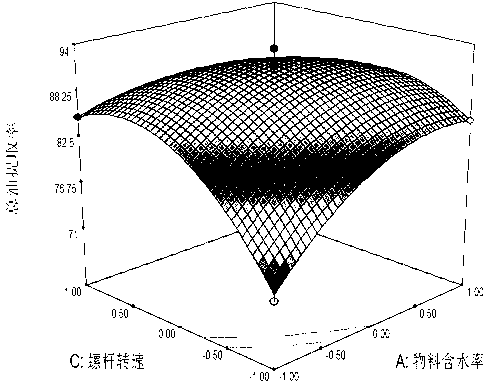

[0042] On the basis of the single factor test, the three factors of material moisture content, cold pressing temperature, and screw speed were selected as independent variables, and the response value of the total oil extraction rate was used to design a response surface analysis test. The factor level coding table is shown in Table 2 -1.

[00...

Embodiment 2

[0060] Example 2: Screening test for optimal parameters of cold-pressed sesame cake enzymatic hydrolysis process

[0061] 1 Materials and methods

[0062] 1.1 Materials and reagents

[0063]

[0064] 1.2 Main instruments and equipment

[0065]

[0066] 1.3 Test method

[0067] 1.3.1 Process flow

[0068] Sesame→peeling→low temperature tempering→cold pressing→cold pressing sesame cake→crushing→mixing with water→heat treatment→enzyme hydrolysis→enzyme inactivation→alkaline extraction→centrifugal separation→sesame oil

[0069] 1.3.2 Calculation formula

[0070]

[0071] 2 Results and discussion

[0072] 2.1 Level coding table of experimental factors

[0073] On the basis of the single factor test, four factors including enzymatic hydrolysis temperature, enzymatic hydrolysis time, enzyme amount, and liquid-solid ratio were selected as independent variables, and the response value was the total oil extraction rate. According to the central combination design principle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com