Automobile exhaust catalyst and prepared catalytic converter thereof

A technology for automobile exhaust and catalyst, applied in exhaust devices, mechanical equipment, machines/engines, etc., can solve problems such as affecting engine power, increasing the reaction area of catalysts, increasing the content of precious metals, etc., to ensure the light-off temperature and light-off time, improve catalytic conversion efficiency, and ensure the effect of engine power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

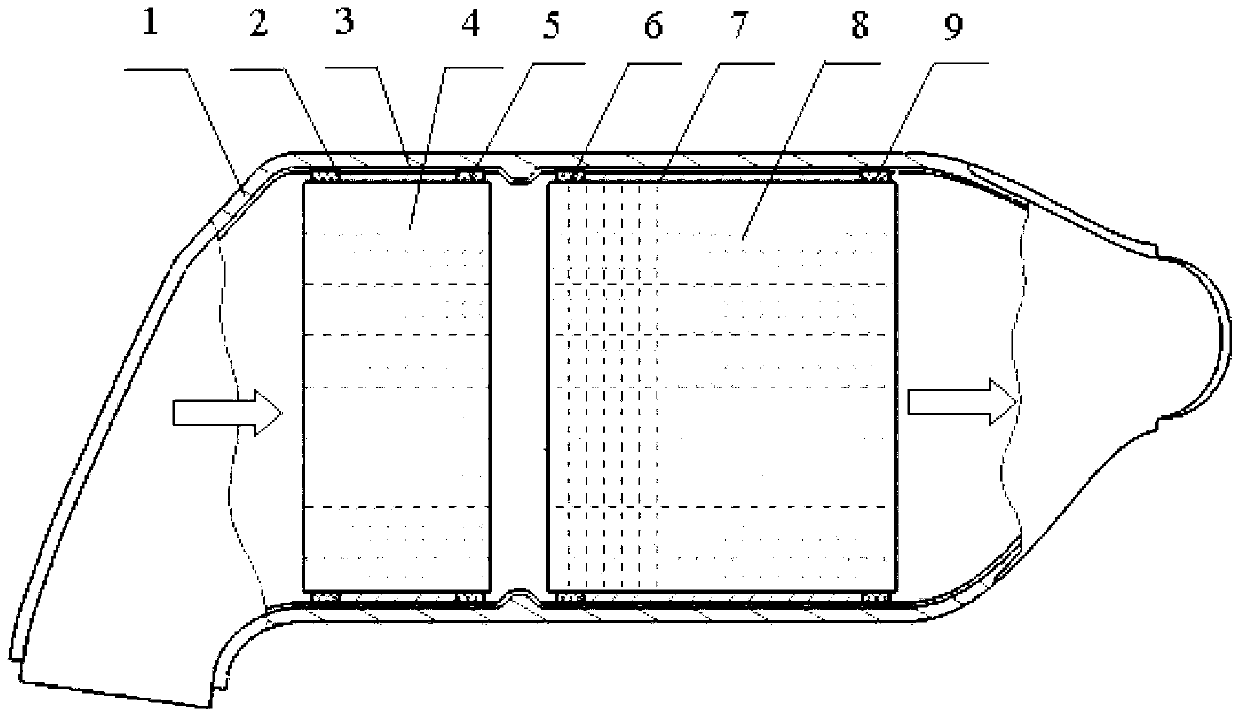

[0043] Embodiment 1 The impact of carrier mesh number on catalytic converter

[0044] In the present invention, the mesh numbers of the front-end carriers are respectively 4.3 / 600, 3.5 / 600, and 2.5 / 900, and the mesh numbers of the back-end carriers are respectively 6.5 / 400, 5.5 / 350, and 4.3 / 400 to detect the influence on the entire catalytic converter.

[0045] The result is as Figure 4a , 4b As shown, the conclusions are as follows:

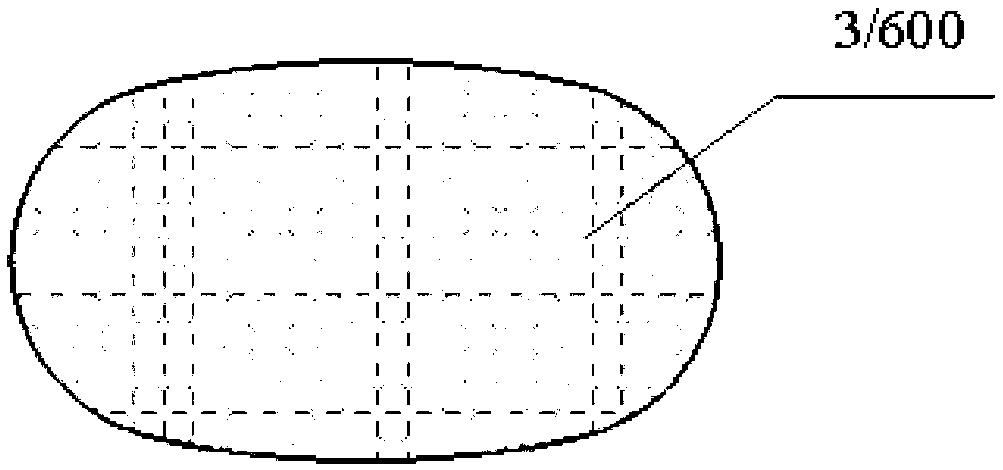

[0046] 1) According to the above comparison of heat capacity, purification effect and back pressure loss, it can be seen that the parameters of the carrier mesh number 2 / 900 are relatively high, but the carrier body wall with a mesh number of 2 / 900 is relatively thin, the strength is poor and The cost of the carrier is relatively high. Considering the actual situation of weak domestic packaging capabilities, the number of front-end carriers is selected as 3 / 600, and the number of back-end carriers is selected as 4 / 400 considering the contribu...

Embodiment 2

[0049] The influence of embodiment 2 coating on whole catalytic converter

[0050] In this example, the front and rear end coatings of three different formulations in Table 1 are selected. Scheme 1 and Scheme 2 respectively use front-end carriers and rear-end carriers with different ratios of precious metals. In addition, the rear-end carrier of Scheme 2 adopts quantitative coating. The back-end carrier of 3 is coated with the partition of the present invention, see Table 1 for details.

[0051] Table 1 Comparison table of coating emission results of different formulations and schemes

[0052]

[0053] According to the emission calibration results of the three schemes in Table 1:

[0054] In view of the high content of HC and NMHC during emission calibration, the front-end carrier of the catalyst is coated with single palladium (Pd) (palladium can mainly promote the oxidation of HC and CO) to remove rhodium (Rh) in the front-end carrier of the original catalyst Metal, rho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com