High-production-efficiency laser linear light source assembly and assembly method thereof

A technology of laser line light source and assembly method, which is applied in the direction of optical components, light source fixing, optics, etc., can solve the problems of low production efficiency, high processing cost, and difficult debugging, and achieve high production efficiency, low production cost, and difficult debugging small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

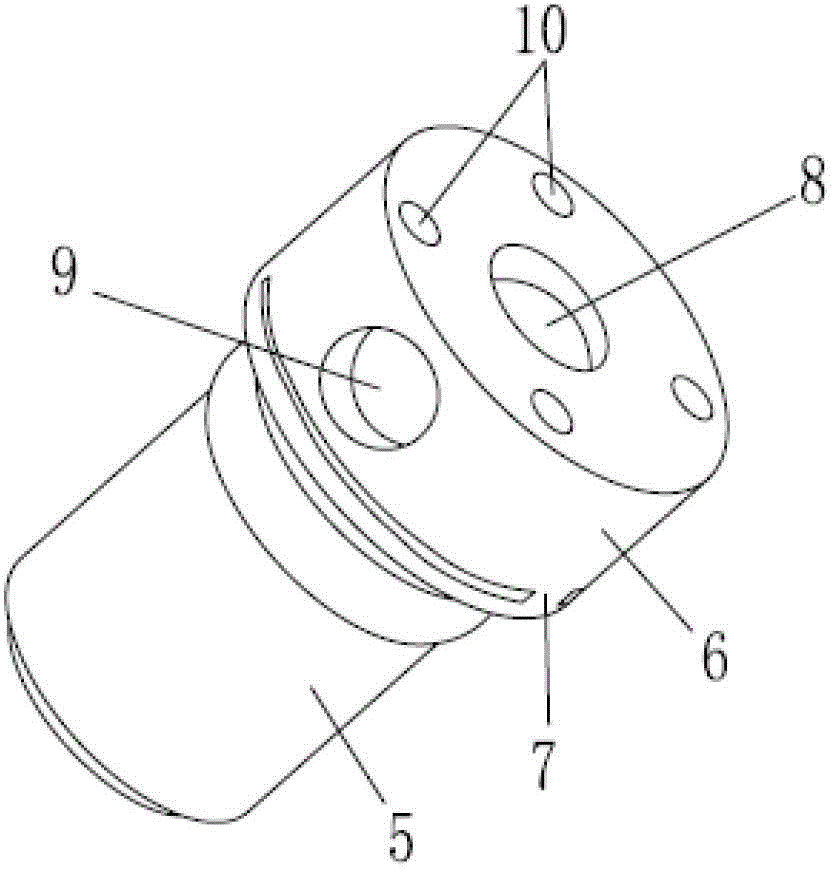

[0027] See Figure 4-5 , the body of the laser line light source assembly of the present embodiment includes: a body, the body includes: a hollow cylindrical main body 5 and a laser generating assembly 13 arranged in the main body 5; There is a radially penetrating assembly groove 11, which is provided with a radially distributed cylindrical lens 1; the bottom surface of the assembly groove 11 is provided with a pair of radially symmetrically distributed and oppositely arranged inclined surfaces 12; by adjusting The position of the cylindrical lens 1 on the pair of inclined surfaces 12 is used to fine-tune the angle between the central axis of the cylindrical lens 1 and the laser beam output by the laser generating assembly 13; when the angle is a right angle, Both ends of the cylindrical lens 1 are fixed with glue.

[0028] As an optimal embodiment, the inclined surface 12 is an arc-shaped inclined surface matched with the end of the cylindrical lens 1, so that the contact b...

Embodiment 2

[0033] The assembly method of the laser line light source assembly in the above-mentioned embodiment 1 includes the following steps:

[0034] A. Fix the laser generating assembly 13 in the main body 5, and make the laser beam output by the laser generating assembly 13 suitable for passing through the central through hole 15;

[0035] B. The cylindrical lens 1 is arranged radially on the pair of inclined surfaces 12 in the fitting groove 11;

[0036] C, fix the elastic reed 14 on the top surface of the top end portion 6, to compress the cylindrical lens 1;

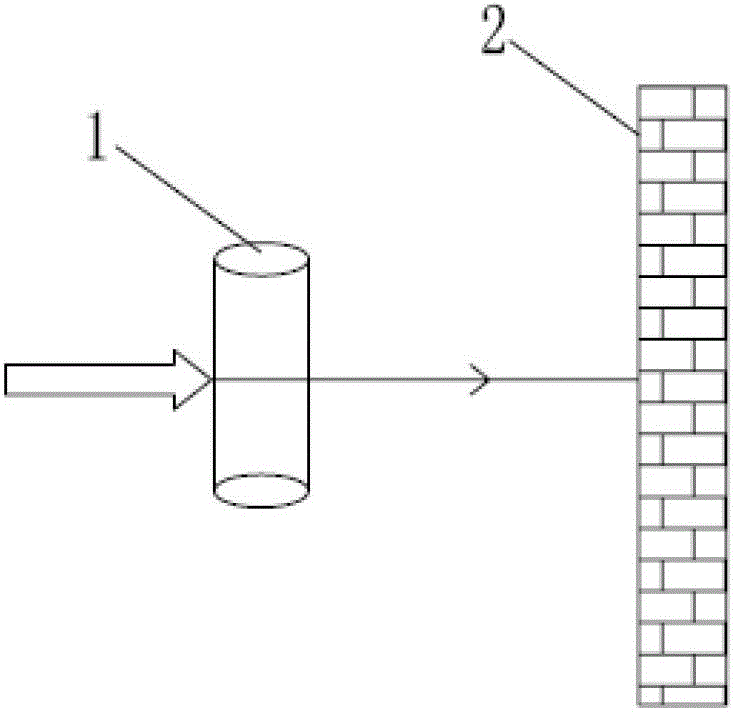

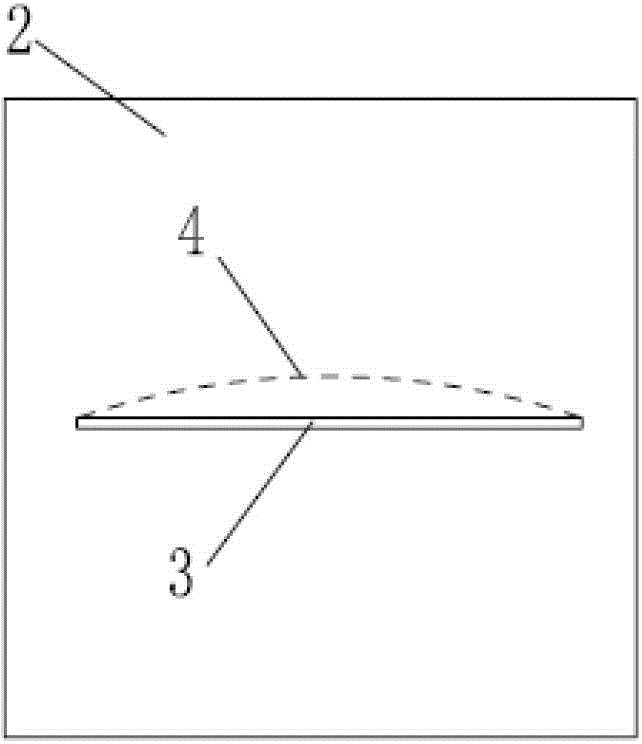

[0037] D. Fix the laser head assembly 13 on a debugging frame, and make the laser head assembly face a wall; a pair of screws are arranged on the debugging frame, and the pair of screws are oppositely arranged at the left and right ends of the cylindrical lens 1 , and is adapted to adjust the left and right positions of the cylindrical lens 1 on the pair of inclined surfaces 12 by synchronously rotating the pair of screws;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com