Hysteresis control method of Boost convertor

A hysteresis control and converter technology, applied in the field of hysteresis control of boost converters, can solve the harsh requirements that cannot meet the performance indicators of boost converters, the increase in the manufacturing cost of DC-DC converters, and the impact of operational amplifiers on the performance of control circuits. and other problems, to achieve the effect of facilitating electromagnetic compatibility design, making up for the lack of dynamic response performance, and not easy to electromagnetic interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Such as figure 1 As shown in the traditional PWM control circuit diagram, Vi is the input voltage, S 1 , S 2 main switching tube, L is the inductance, co is the filter capacitor, C 1 To compensate the network capacitance, f c is the triangular carrier, V rc is the reference voltage, V o 1 is the output voltage.

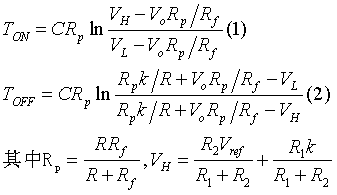

[0025] Such as figure 2 The hysteresis control circuit diagram of the Boost converter of the present invention. Vi is the input voltage, S 1 , S 2 main switching tube, L is the inductance, C is the charging capacitor, co is the filter capacitor, R 1 , R 2 Adjust the resistance for the upper and lower limit thresholds, R f Adjust resistors for feedback, V ref , V rc : reference voltage, R o for the load, R is the branch resistance, R f is the feedback resistor, Vo is the output voltage, V L , V H Low threshold voltage and high threshold voltage for the hysteresis comparator;

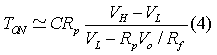

[0026] V n is the hysteresis co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com