Methods of modifying metal-oxide nanoparticles

A technology of nanoparticles and oxides, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve problems such as unsuitable refractive index and optical transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0086] Example of Preparation of Modified Nanoparticles. Specifically, Examples 1, 2 and 3 were prepared. The method of preparing Examples 1, 2 and 3 relates to the first example of the invention. Each instance is described in detail next.

example 1

[0088] A three necked round bottom flask equipped with stirrer, addition funnel, thermometer and Dean Stark trap with condenser was charged with 14.88 g PhSi(OMe) 3 and 12.30 g sol. The sol is zirconium (ZrO 2 ) sol comprising 10% by weight ZrO 2 / toluene solution, and modifiers. The sol had a solids content of 16.6% by weight after 1 hour at 150°C. The composition of the modifier is proprietary and thus unknown, although the modifier is believed to be a surfactant, present in an amount of about 7% by weight. The actual diameter of the nanoparticles is 7 nm. The appearance of the sol was slightly cloudy. The sol is commercially available from Sumitomo Osaka Cement Co., Ltd. Without wishing to be bound or bound by any particular theory, it is believed that the presence of the modifying agent (eg, surfactant) in the sol is particularly beneficial in forming a subsequent homogeneous composition.

[0089] Next, will contain 4.21g water, 1.47g (ViMe 2 Si) 2 A solution of O...

example 2

[0094] Example 2 was prepared in a similar manner to Example 1. The products explored are Vi m 0.15 Ph T 0.75 [ZiO 2 ] 0.10 . Relative to Example 1, KOH equilibration was performed in Example 2 for 16 hours instead of 8 hours. Also, after removing the solvent, the product was a sticky solid rather than a flaky solid.

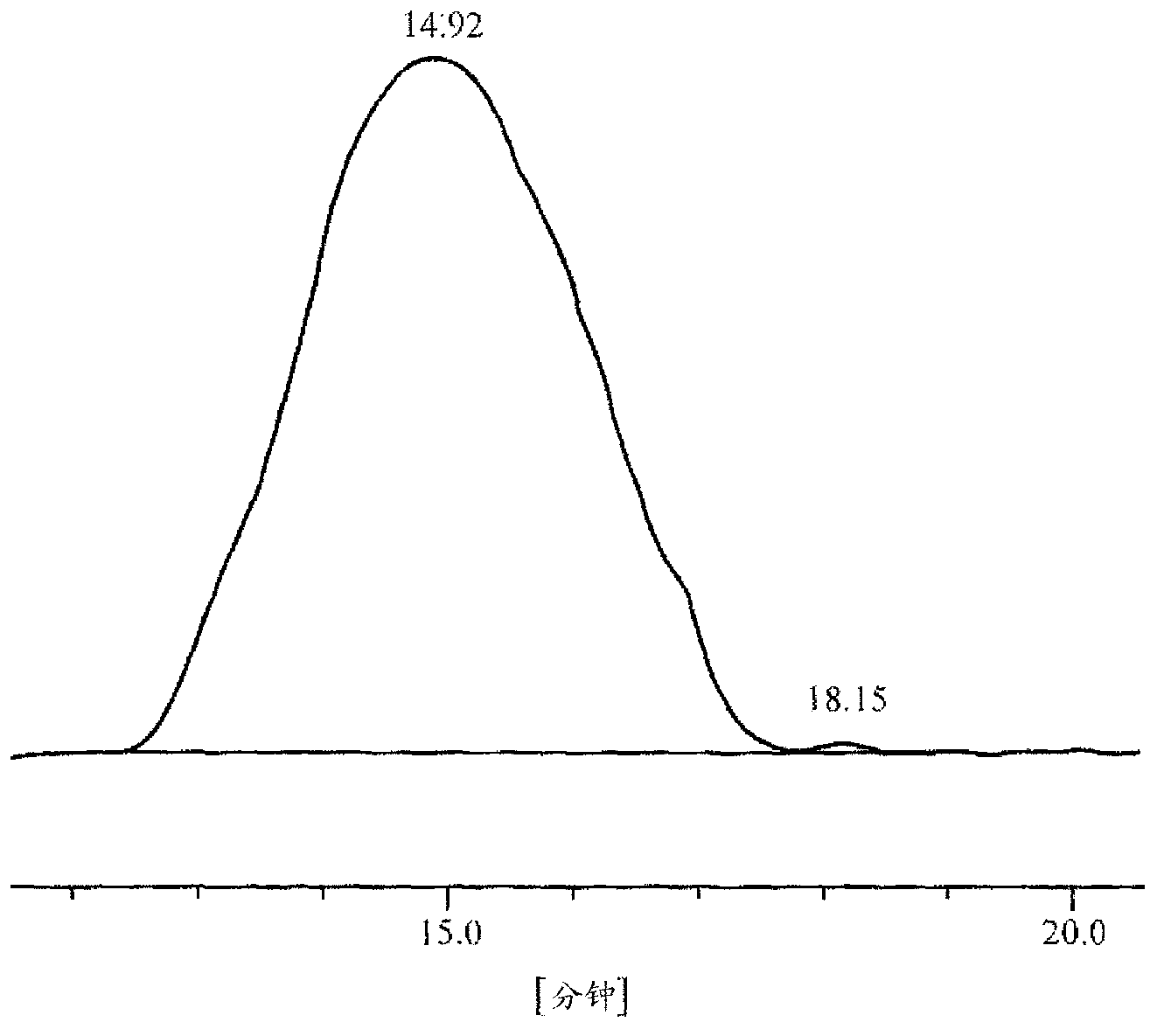

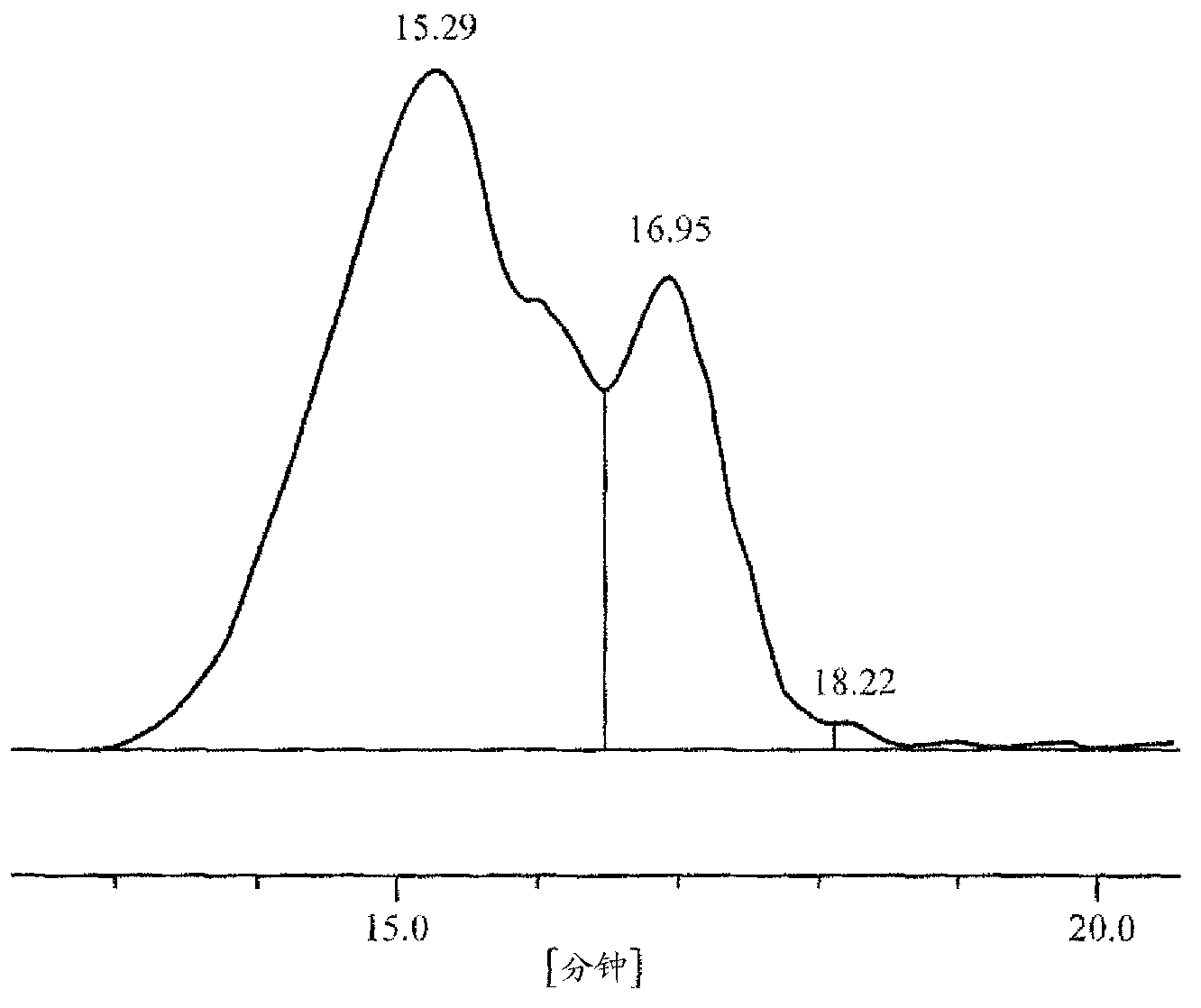

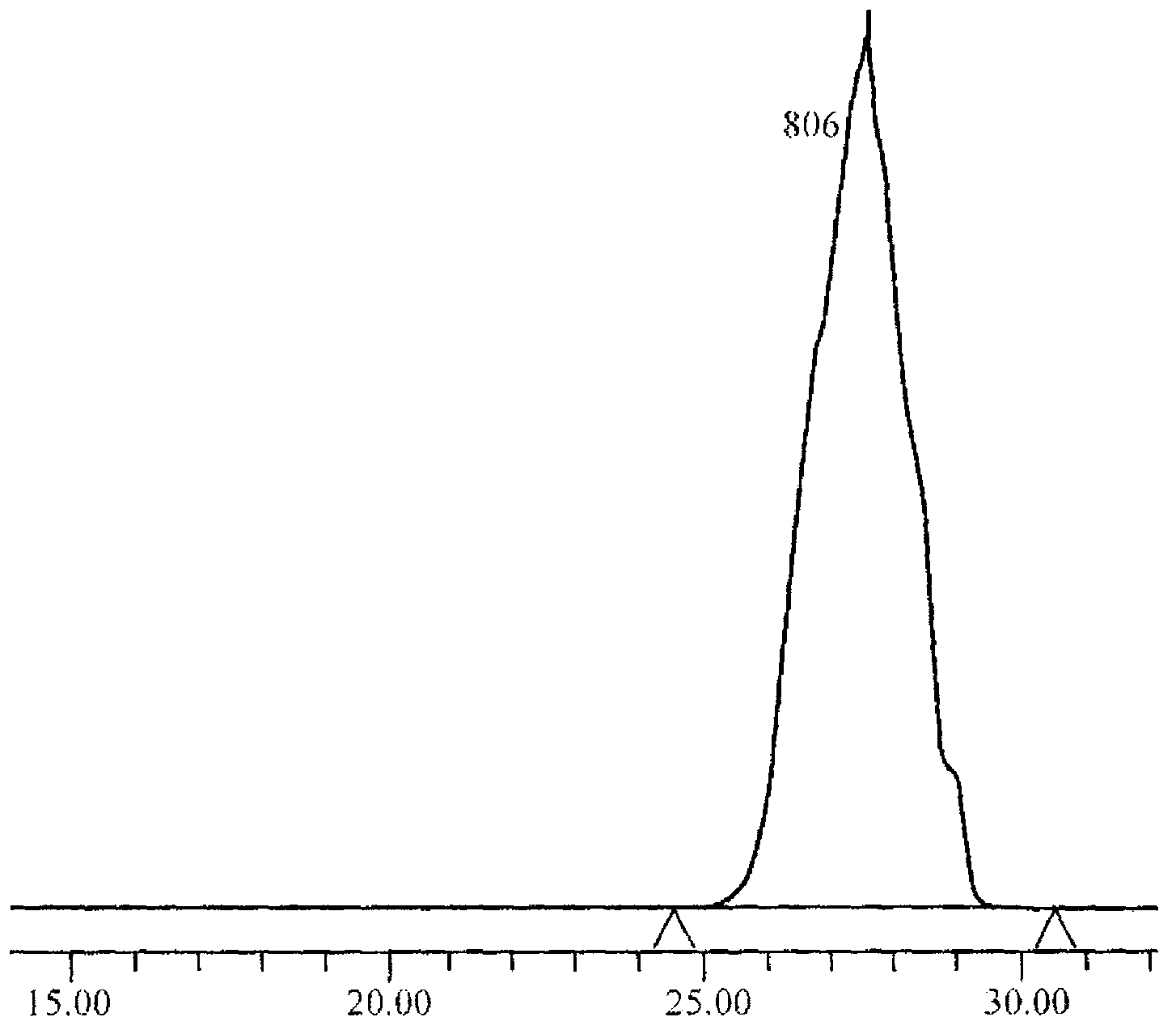

[0095] The product of Example 2 was tested by IR spectroscopy, GPC and NMR by methods known in the art. For IR, observed at 898cm -1 greater absorption. No Si-O-Zr formation was identified. For GPC, relative to the product of Example 1, the molecular weight was much lower and multimodal. GPC testing usually involves the use of CHCl 3 , TSK gel XL-L. For NMR, much more SiOH than Example 1 is present. for 29 Si NMR using D 4 As an internal standard, this yielded a resin content of 81.9% by weight per solid. From this the vinyl content of each solid was determined. The rest of the solid is assumed to be from ZrO 2 , and 50% by weight of the modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com