Anhydrous hydrogen fluoride production method

A technology of anhydrous hydrogen fluoride and production method, applied in the direction of fluorine/hydrogen fluoride, etc., can solve the problems of low product conversion rate and high cost, and achieve the effects of improving product conversion rate and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

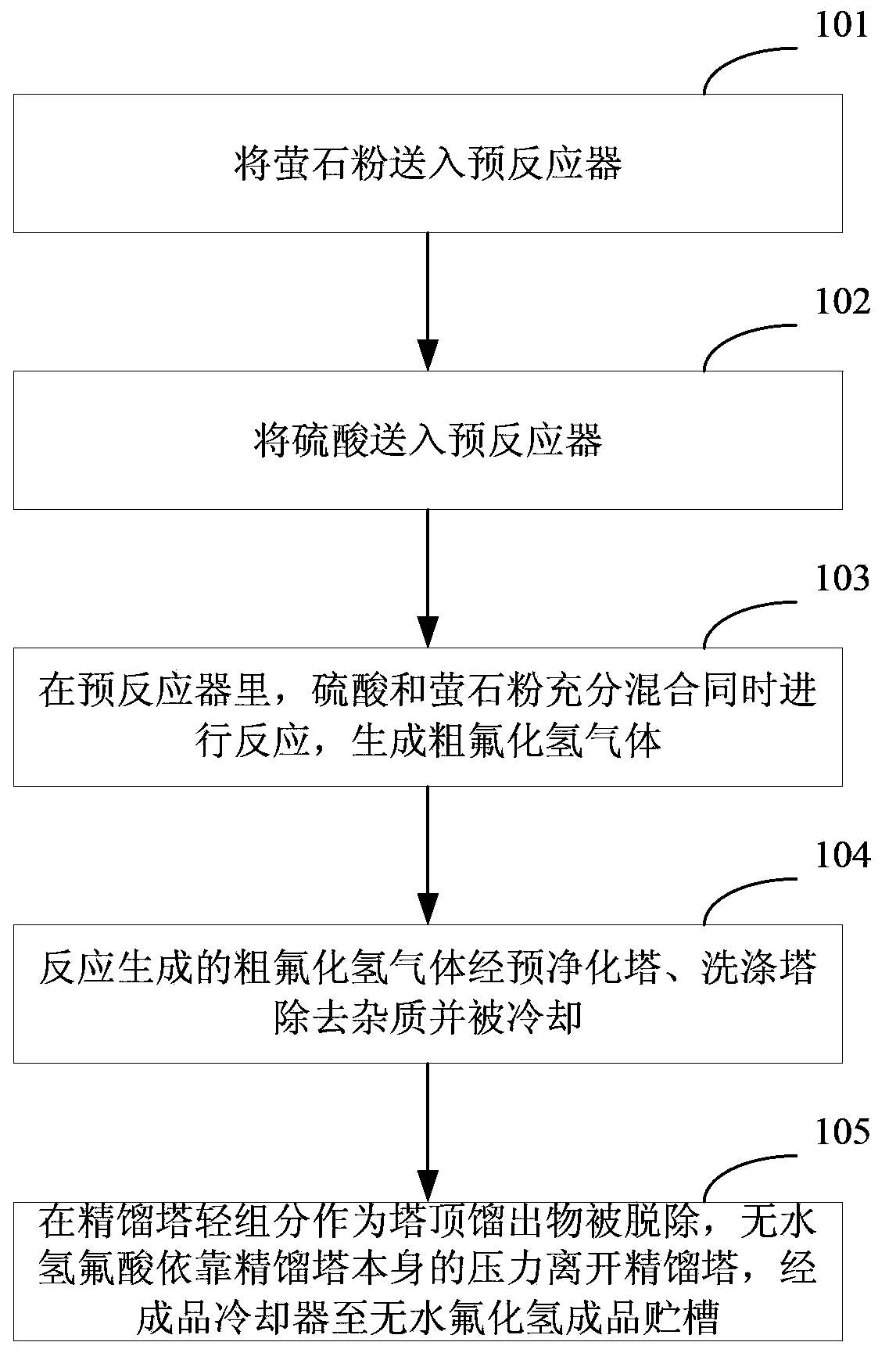

[0022] Embodiments of the present invention provide a method for producing anhydrous hydrogen fluoride, such as figure 1 shown, including the following steps:

[0023] Step 101, sending fluorite powder into the pre-reactor. Specifically: the fluorite powder is transported to the high-level fluorite silo by compressed air from the single-chamber pump, and then sent to the pre-reactor continuously through the fluorite silo, unloading screw, feeding hopper, and fluorite feed scale. Among them, fluorite is also called fluorspar, and its chemical composition is mainly calcium fluoride.

[0024] Step 102, sending sulfuric acid into the pre-reactor. Ordinary sulfuric acid and oleum from the tank area enter the sulfuric acid storage tank and oleum storage tank respectively through the outer pipe, and through the sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com