Sol-gel method for preparing Sm2O3 nanoarray

A nano-array and gel-based technology, applied in nanotechnology, chemical instruments and methods, rare earth metal compounds, etc., to achieve broad research and application value, easy control, and controllable size and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

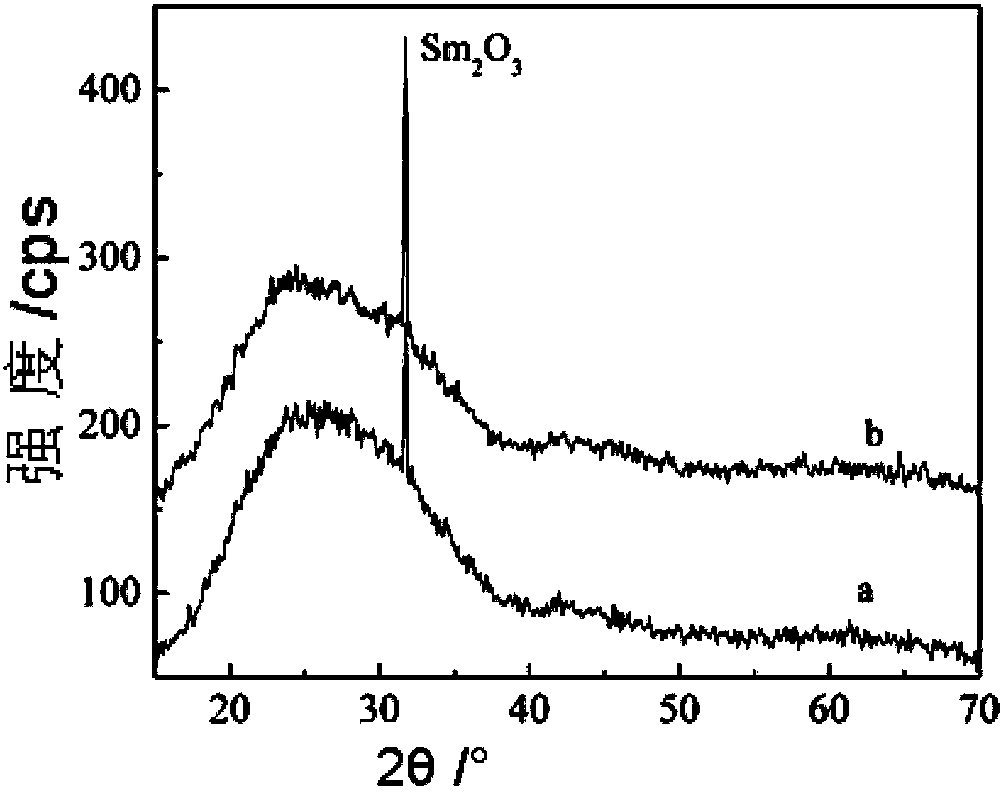

Image

Examples

Embodiment 1

[0019] Step 1: Analyze pure Sm(NO 3 ) 3 ·6H 2 Add O into 30mL deionized water, stir and dissolve on a magnetic stirrer to prepare Sm 3+ A transparent solution with a concentration of 0.01mol / L;

[0020] Step 2: Adjust the pH of the system to 4.5 with a 5% by mass ammonia solution and stir to form a sol, then add 0.5 mL of a 5% by mass polyvinyl alcohol aqueous solution to the sol, and stir evenly for use;

[0021] Step 3: Fully infiltrate the AAO template (Hefei Puyuan Nano Co., Ltd.) with a pore diameter of 20~80nm, a template diameter of Φ25~50mm, and a nanometer pore length of 10~20μm with the above sol, and clean the ITO conductive glass substrate After bonding, place it in a high-temperature drying box and dry it at 60-80°C for 1 to 2 days to make the sol slowly lose water and turn it into a gel. Then heat it at 300°C for 3 hours and then cool it down in the furnace;

[0022] Step 4: Polish the surface of the AAO template with (16±1)μm (1500 mesh) fine sandpaper, wash with deion...

Embodiment 2

[0024] Step 1: Analyze pure Sm(NO 3 ) 3 ·6H 2 Add O into 30mL deionized water, stir and dissolve on a magnetic stirrer to prepare Sm 3+ A transparent solution with a concentration of 0.05mol / L;

[0025] Step 2: Adjust the pH of the system to 5.0 by using 5% by mass ammonia solution and stir to form a sol, then add 1.5 mL of 5% by mass polyvinyl alcohol aqueous solution to the sol, and stir evenly for use;

[0026] Step 3: Fully infiltrate the AAO template (Hefei Puyuan Nano Co., Ltd.) with a pore diameter of 20~80nm, a template diameter of Φ25~50mm, and a nanometer pore length of 10~20μm with the above sol, and clean the ITO conductive glass substrate After bonding, place it in a high-temperature drying box and dry it at 60-80°C for 1 to 2 days to make the sol slowly lose water and turn it into a gel, and then heat it at 320°C for 2.5 hours and then cool it in the furnace;

[0027] Step 4: Polish the surface of the AAO template with (16±1)μm (1500 mesh) fine sandpaper, wash with deio...

Embodiment 3

[0029] Step 1: Analyze pure Sm(NO 3 ) 3 ·6H 2 Add O into 30mL deionized water, stir and dissolve on a magnetic stirrer to prepare Sm 3+ A transparent solution with a concentration of 0.1mol / L;

[0030] Step 2: Adjust the pH of the system to 5.5 with 5% by mass aqueous ammonia solution and stir to form a sol, then add 0.8 mL of 5% by mass polyvinyl alcohol aqueous solution to the sol, and stir evenly for use;

[0031] Step 3: Fully infiltrate the AAO template (Hefei Puyuan Nano Co., Ltd.) with a pore diameter of 20~80nm, a template diameter of Φ25~50mm, and a nanometer pore length of 10~20μm with the above sol, and clean the ITO conductive glass substrate After bonding, place it in a high-temperature drying box and dry it at 60-80°C for 1 to 2 days to make the sol slowly lose water and turn it into a gel. Then heat it at 350°C for 2h and then cool it down in the furnace;

[0032] Step 4: Polish the surface of the AAO template with (16±1)μm (1500 mesh) fine sandpaper, wash with deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com