Optical engine structure with same substrate

A light engine and substrate technology, applied in the field of lighting, can solve the problems of difficult standardization, poor matching, complicated processes, etc., and achieve the effects of good matching, improved light efficiency, and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

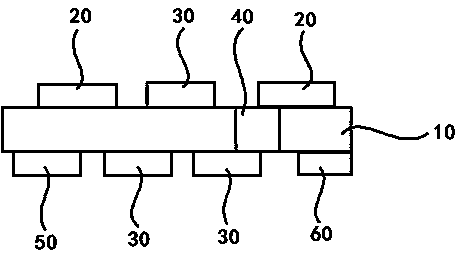

[0022] as attached figure 1 As shown, the same-substrate light engine structure described in Embodiment 1 includes an aluminum or aluminum alloy substrate 10, the substrate includes a first main surface and a second main surface opposite to the first main surface, and the substrate 10 is Integrated with LED light source 20 and LED constant current driver 30, the LED light source is an LED chip or LED lamp bead, and the LED light source 20 and LED constant current driver 30 are arranged on any main surface or on two main surfaces at the same time. On the surface; the LED constant current driver 30 is electrically connected to the LED light source 20; and the LED constant current driver 30 is used to convert the input direct current or alternating current into a steady current, and the steady current is supplied to the LED light source 20, and complete the electro-optic conversion to emit illumination light. The LED light source can be combined on the substrate by means of die ...

Embodiment 2

[0024] Compared with Example 1, the only difference is that a different substrate is used. Moreover, the substrate is a highly thermally conductive insulating printed circuit board; the printed circuit board includes a metal base, a ceramic layer sequentially formed on the metal base, and a metal conductive layer formed on the ceramic layer.

[0025] Preferably, the high thermal conductivity insulating aluminum-based printed circuit board includes a metal aluminum substrate, an aluminum transition layer sequentially formed on the metal aluminum substrate, an AlON ceramic coating formed by an arc ion plating method, and A metal conductive coating formed on a coating. The aluminum-based printed circuit board is prepared by the above method, wherein the step of depositing the aluminum transition layer adopts the following process: the target used is an aluminum sputtering target with a purity of 99.99 wt%, and the background vacuum degree of the vacuum chamber is 5×10 -4 Pa, th...

Embodiment 3

[0027] Compared with Example 1, the only difference is that a different substrate is used. Moreover, the substrate is a highly thermally conductive fluorescent insulating printed circuit board; the printed circuit board includes a metal base, a thermally conductive fluorescent ceramic layer formed sequentially on the metal base, and a metal conductive layer formed on the thermally conductive fluorescent ceramic layer.

[0028] The high thermal conductivity fluorescent insulating printed circuit board includes a fluorescent insulating layer and a metal circuit layer sequentially formed on a metal base. The metal substrate can be metal plates such as Al, Cu, Ag and Ni or their alloy plates; the metal circuit layer is formed by dry or wet etching through the deposited conductive metal layer, and the conductive The metal is generally preferably Cu, Ag, Al or alloy materials thereof. The fluorescent insulating layer can be formed by various known coating methods, for example, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com