Preparation method preparation device of photocuring high strength fiber for dental repair

A technology of high-strength fiber and dental restoration, which is applied in the field of preparation of materials for dental restoration, can solve problems such as inconvenient clinical operation, deviation of overall mechanical properties, and incompatibility of interface properties, so as to save raw materials and improve production efficiency , clear and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] According to Bis-GMA (bisphenol A glycidyl methacrylate): TEGDMA (triethylene glycol dimethacrylate): CQ (camphorquinone): DMAEMA (dimethylaminoethyl methacrylate) mass fraction ratio For: 90:10:0.5:0.5 to configure the final photocurable resin system.

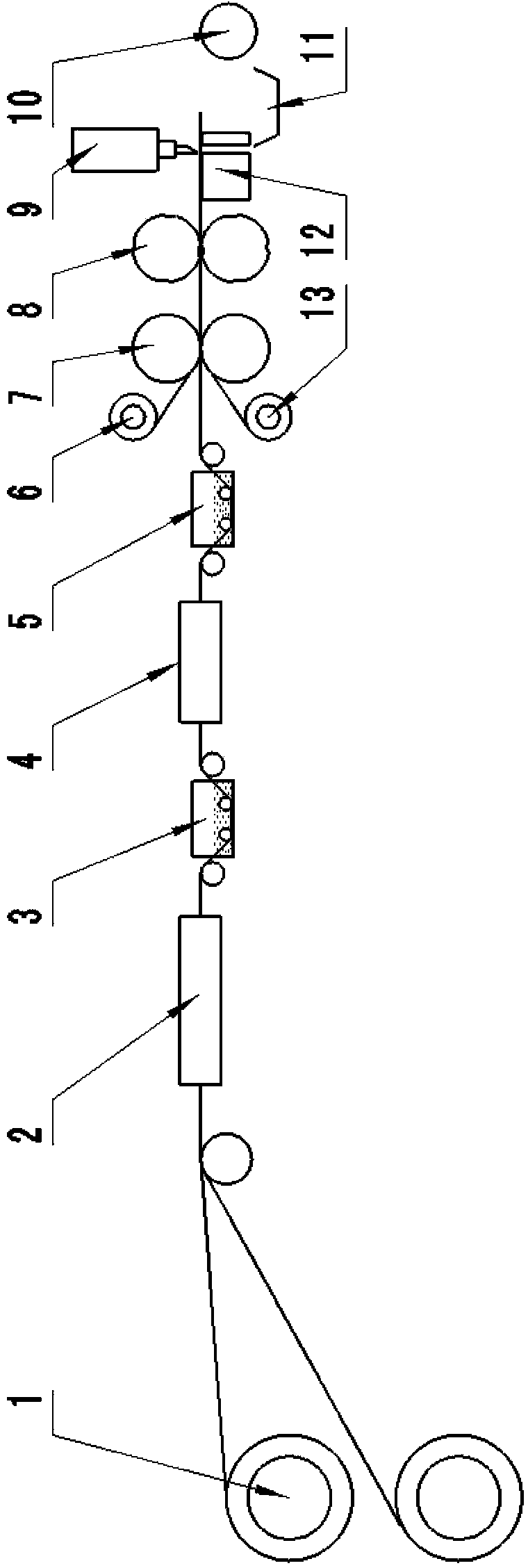

[0041] The multi-bundle glass fiber filaments enter the dehumidification furnace 2 through the wire rack 1 and the wire discharge hole of the wire collecting plate. The temperature of the furnace is 120°C, and the pulling speed is 0.5m / min. In the groove, be the PMMA acetone solution (molecular weight 200000g / mol) of 2% mass percentage composition, the glass fiber after dipping is through heating furnace 80 ℃ of heating evaporation acetone, the mass percentage composition that PMMA is adsorbed on the fiber after measuring is 0.3%, as in image 3 Shown; Then enter a dipping tank II, the tank is a light-curing resin system. After friction traction wheel I and friction traction wheel II, the prepreg is obtained under the...

Embodiment 2

[0043] According to embodiment 1, it is 5% to change the concentration of the PMMA acetone solution of the first dipping tank, and the mass percent composition that PMMA absorbs on the fiber is 0.9% after measuring, as Figure 4 shown. The temperature for evaporating the solvent is 80° C., and other operations are the same as in Example 1. According to the ISO10477 standard, the prepared prepreg samples were made into 2×2×25mm to test the flexural strength and flexural modulus. The measured flexural strength of the composite material is 546.3±60.3MPa, and the flexural modulus is 9.1±0.9GPa. Its interface combines as Figure 7 shown.

Embodiment 3

[0045] According to Bis-GMA (bisphenol A glycidyl methacrylate): polyethylene glycol dimethacrylate: CQ (camphorquinone): DMAEMA (dimethylaminoethyl methacrylate) mass fraction ratio: 80 : 20: 0.5: 0.5 configured as the final photocurable resin system.

[0046] A plurality of bundles of quartz fibers enter the dehumidification furnace 2 through the wire rack 1 and the wire discharge hole of the wire collecting plate. The furnace temperature is 100°C, and the pulling speed is 0.2m / min. In the groove, be the THF (tetrahydrofuran) solution (molecular weight 500000g / mol) of PLA (polylactic acid) that mass percentage is 10%. The fiber is heated in a heating furnace at 150°C to evaporate the solvent; then it enters the next dipping tank II, which contains a light-curing resin system. After friction traction wheel I and friction traction wheel II, the prepreg is obtained under the traction of traction wheel 10, all of the above operations are carried out in a dark room. According t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com