Photochemical kettle for refluxing phosgene at bottom and method for preparing hexamethylene diisocyanate

A photochemical kettle and phosgene technology, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of isocyanic acid derivatives, etc., can solve problems such as large consumption of phosgene, low boiling point of phosgene, and vaporization

Inactive Publication Date: 2013-10-23

甘肃银光聚银化工有限公司

View PDF4 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Usually, the condensed reflux liquid is designed to enter from the top of the reactor. In this case, the problem is that the gas phase of the reactor has a certain temperature, especially the temperature of the thermal photochemical reactor is higher, and the boiling point of phosgene is low, so it flows back into the reactor quickly. vaporized

As a result, on the one hand, the amount of phosgene that actually enters the reaction liquid phase for circulation is small, and on the other hand, the vaporized phosgene enters the condenser, and this cycle increases the load of the condenser and reduces the condensation efficiency. As a result, a large amount of excess phosgene is pumped into the tail gas treatment system for destruction treatment together with hydrogen chloride, which leads to a large consumption of phosgene and an increase in cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0044] Embodiment 1: process condition control is as follows table:

[0045]

Embodiment 2

[0046] Embodiment 2: process condition control is as follows table:

[0047]

Embodiment 3

[0048] Embodiment 3: process condition control is as follows table:

[0049]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

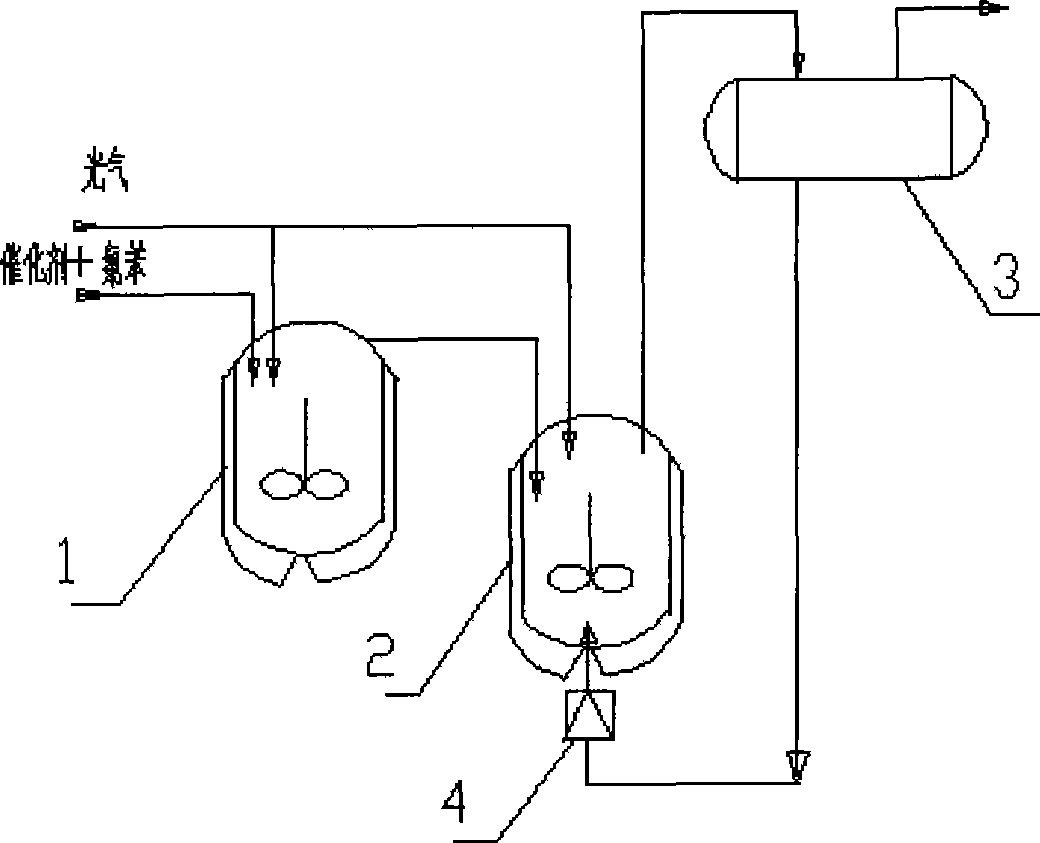

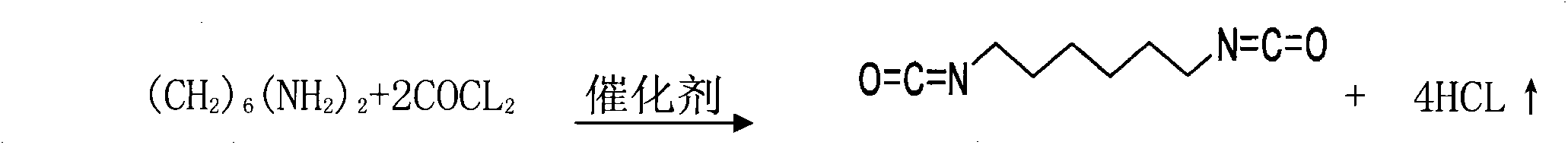

The invention relates to production equipment and a method for fat diisocyanate, in particular to production equipment and a method for preparing hexamethylene diisocyanate by using a phosgene method. A photochemical kettle for refluxing phosgene at bottom is characterized in that a phosgene condensate reflux pipeline enters from the bottom of a reaction kettle, wherein a check valve (4) is additionally arranged on the inlet part; all the condensed liquid-phase phosgene refluxes into a reaction liquid system from the bottom of a thermal photochemical kettle (2) through the check valve (4); only the material in the reflux pipeline can enter the reaction kettle, but the material in the reaction kettle cannot enter the reflux pipeline, so that reaction is prevented from occurring in the pipeline. The phosgene consumption after improvement is 1.5-2 times the theoretical using amount of the phosgene in photochemical synthesis reaction. The method can be applied to a chemical device of which an excess amount of low boiling point substance participates in reaction, the reaction system temperature is relatively higher and an excess amount of substance is required to be recovered and fed back for recycling.

Description

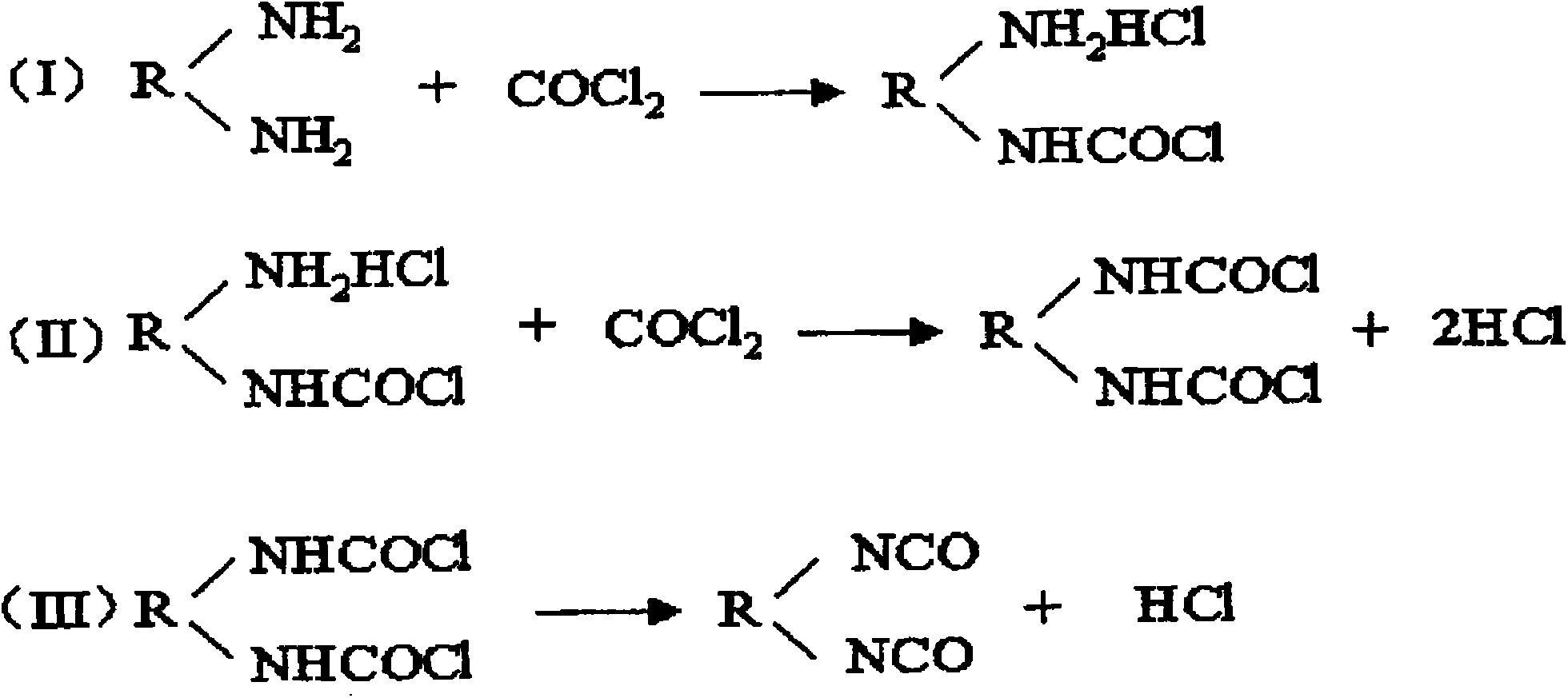

technical field [0001] The present invention relates to the production equipment and method of aliphatic diisocyanate, in particular to the production equipment and method of preparing hexamethylene diisocyanate by phosgene method. Background technique [0002] As an important class of organic chemical intermediates, isocyanates are widely used in industry, agriculture, medicine and health. These compounds are widely used in the synthesis of polyisocyanates, polyurethanes, polyureas, polymer adhesives, insecticides, herbicides, etc. Hexamethylene diisocyanate (1,6-hexamethylene diisocyanate, English abbreviation HDI) is the aliphatic isocyanate with the largest demand in the polyurethane industry at present, and has become the successor toluene diisocyanate (TDI), diphenylmethane diisocyanate (MDI ), polymethyl polyphenylene isocyanate (PAPI), isocyanate species with large demand, mainly used in the production of automotive OEM coatings and repair paints, aircraft OEM coati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J19/08C07C265/14C07C263/10

CPCY02P20/584

Inventor 余咸旱白卫兵陶春霞张克武

Owner 甘肃银光聚银化工有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com