Method for preparing structural color film based on layer-by-layer assembly technology and product and application thereof

A layer-by-layer assembly and structural color technology, which is applied in the field of structural color film preparation, can solve problems that have not been studied by anyone, and achieve the effects of strong controllability, easy operation, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

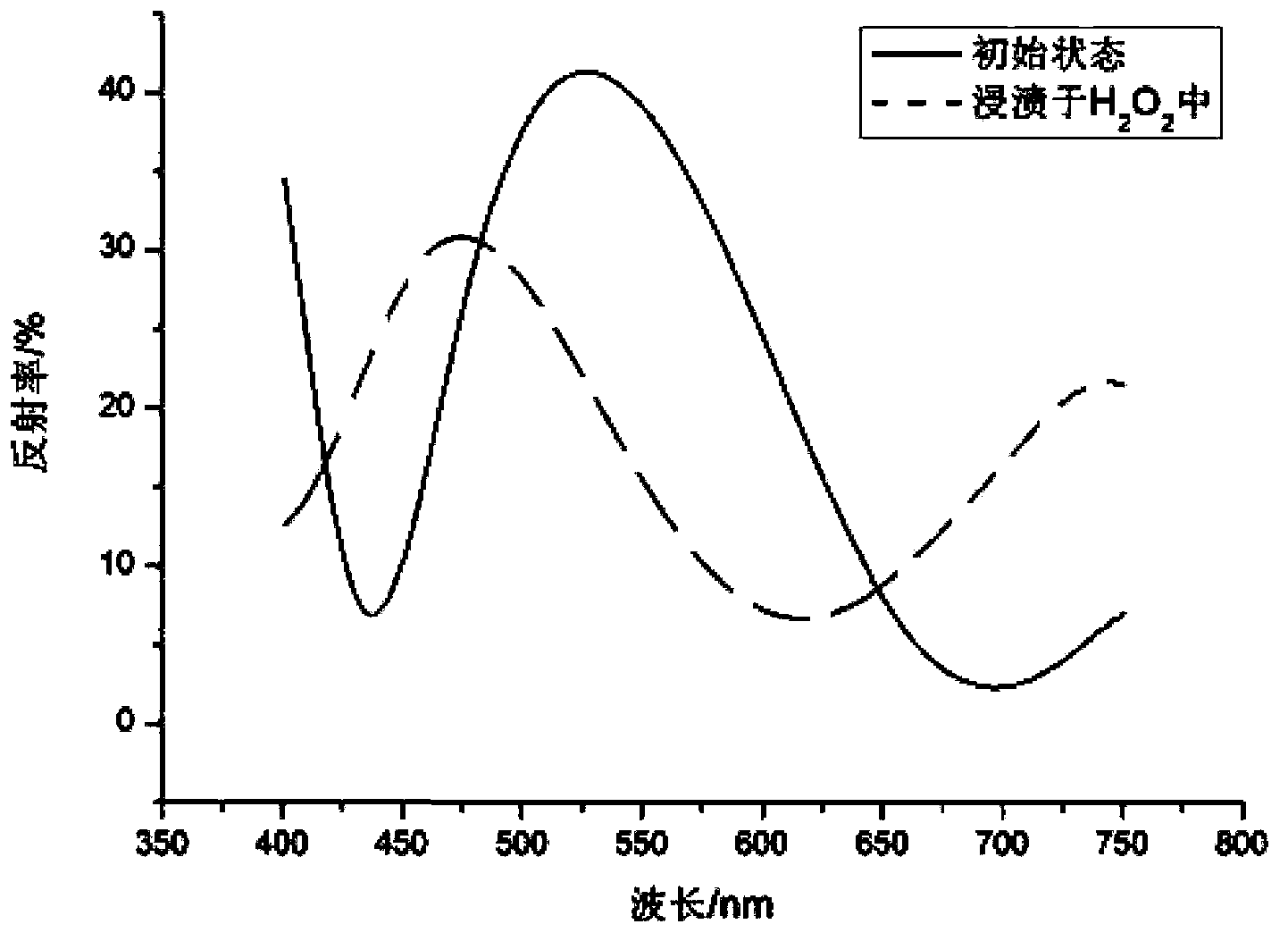

Embodiment 1

[0026] A preparation method of a structured color thin film based on layer-by-layer assembly technology, the specific preparation method is as follows:

[0027] 1) Prepare graphene oxide solution with water as solvent, the concentration of graphene oxide is 0.1mg·mL -1 . Slowly add glacial acetic acid dropwise to the mixed solution of tetrabutyl titanate and absolute ethanol, the volume ratio of the three is 1:1:16, stir for 5 hours and let it stand overnight, the concentration of the obtained titanium dioxide solution is 13.0mg· mL -1 . Mix concentrated sulfuric acid with a volume fraction of 95%-98% and a concentrated hydrogen peroxide solution with a volume fraction of 30% according to a volume ratio of 3:1 to prepare Piranha lotion;

[0028] 2) Wash the silicon wafer as the substrate three times with pure water, then soak the silicon wafer in acetone for 1 hour, wash it with pure water three times, then soak it in absolute ethanol for 1 hour, wash it with pure water thr...

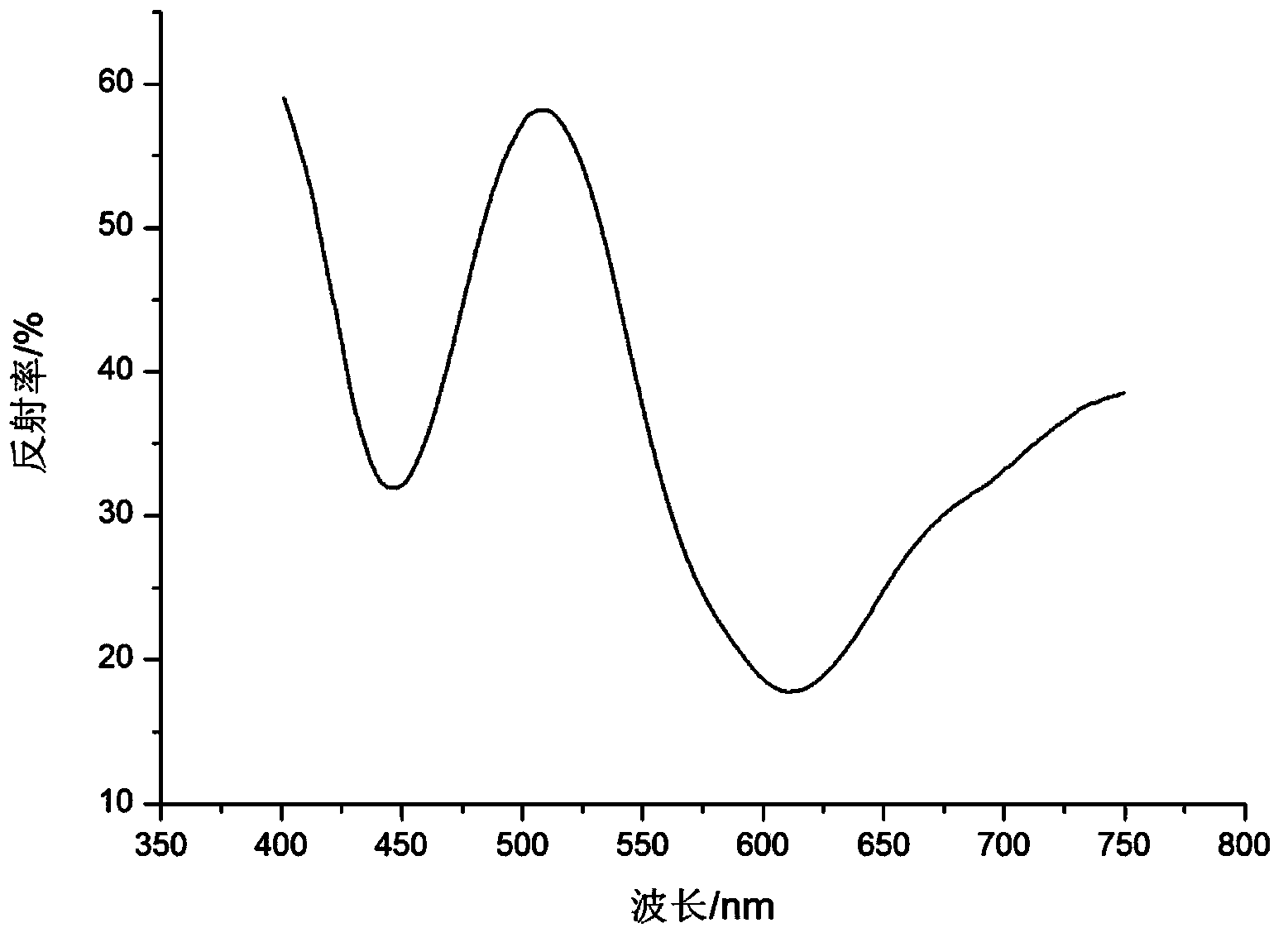

Embodiment 2

[0034] 1) Prepare graphene oxide solution with water as solvent, the concentration of graphene oxide is 0.1mg·mL -1 . Slowly add glacial acetic acid dropwise to the mixed solution of tetrabutyl titanate and absolute ethanol, the volume ratio of the three is 1:1:22, stir for 5h and then let it stand overnight, the concentration of the obtained titanium dioxide solution is 9.8mg· mL -1 . Mix concentrated sulfuric acid with a volume fraction of 95%-98% and a concentrated hydrogen peroxide solution with a volume fraction of 30% according to a volume ratio of 3:1 to prepare Piranha lotion;

[0035] 2) Wash the silicon wafer as the substrate three times with pure water, then soak the silicon wafer in acetone for 1 hour, wash it with pure water three times, then soak it in absolute ethanol for 1 hour, wash it with pure water three times, soak it in Piranha lotion 24h, then washed with pure water, finally dried with nitrogen, and placed on a spin coater;

[0036] 3) Add titanium d...

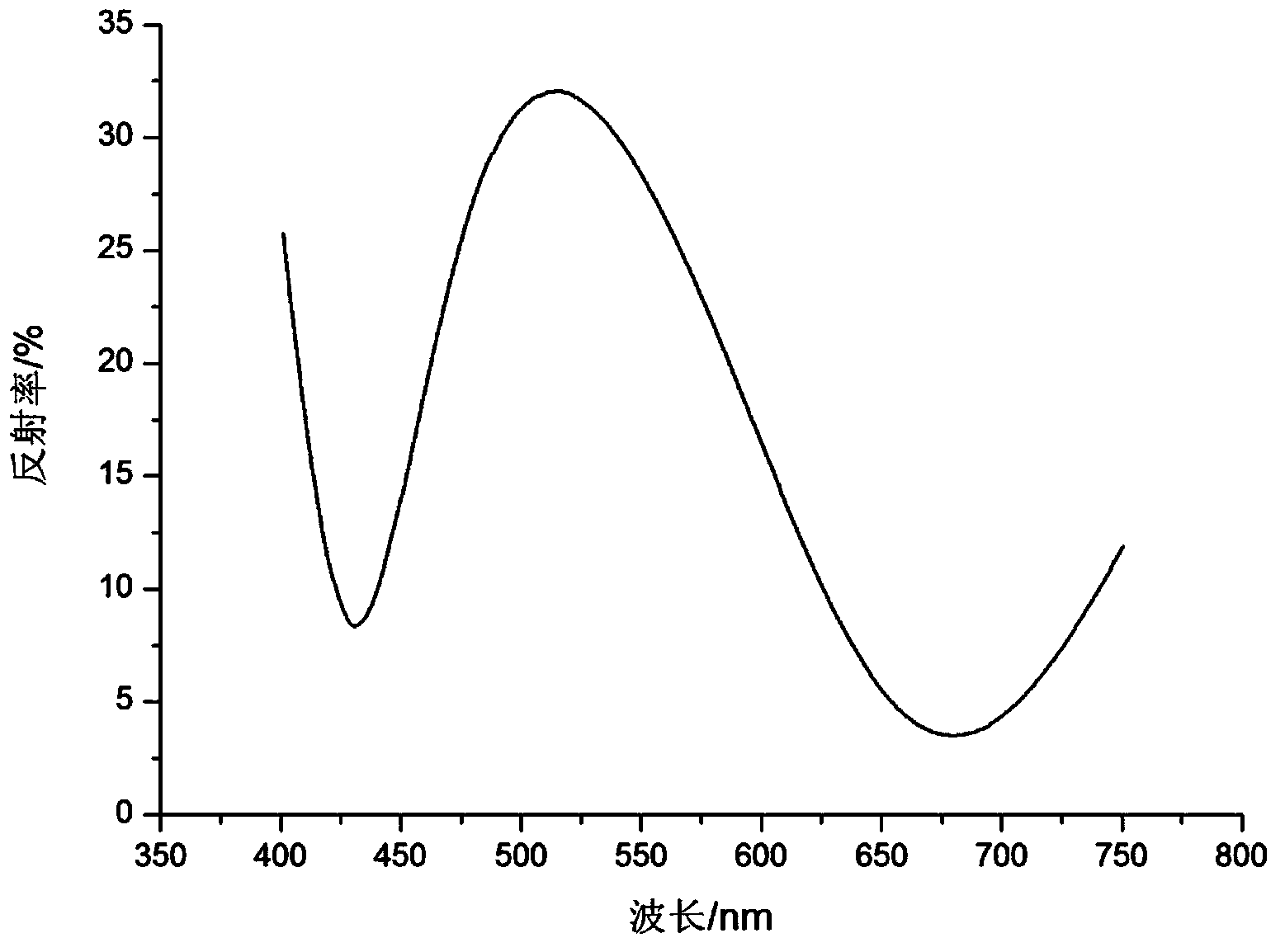

Embodiment 3

[0041] 1) Prepare graphene oxide solution with water as solvent, the concentration of graphene oxide is 0.1mg·mL -1 . Slowly add glacial acetic acid dropwise to the mixed solution of tetrabutyl titanate and absolute ethanol, the volume ratio of the three is 1:1:28, stir for 5 hours and let it stand overnight, the concentration of the obtained titanium dioxide solution is 7.8mg· mL -1 . Mix concentrated sulfuric acid with a volume fraction of 95%-98% and a concentrated hydrogen peroxide solution with a volume fraction of 30% according to a volume ratio of 3:1 to prepare Piranha lotion;

[0042]2) Wash the silicon wafer as the substrate three times with pure water, then soak the silicon wafer in acetone for 1 hour, wash it with pure water three times, then soak it in absolute ethanol for 1 hour, wash it with pure water three times, soak it in Piranha lotion 24h, then washed with pure water, finally dried with nitrogen, and placed on a spin coater;

[0043] 3) Add titanium di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com