Epoxy potable water tank paint and its preparation method

A technology for drinking water tanks and coatings, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., and can solve problems such as difficulty in adapting to coating process requirements, slow response speed, toxicity and safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] An epoxy drinking water tank coating, the coating is mainly composed of component A and component B in a mass ratio of 8:1:

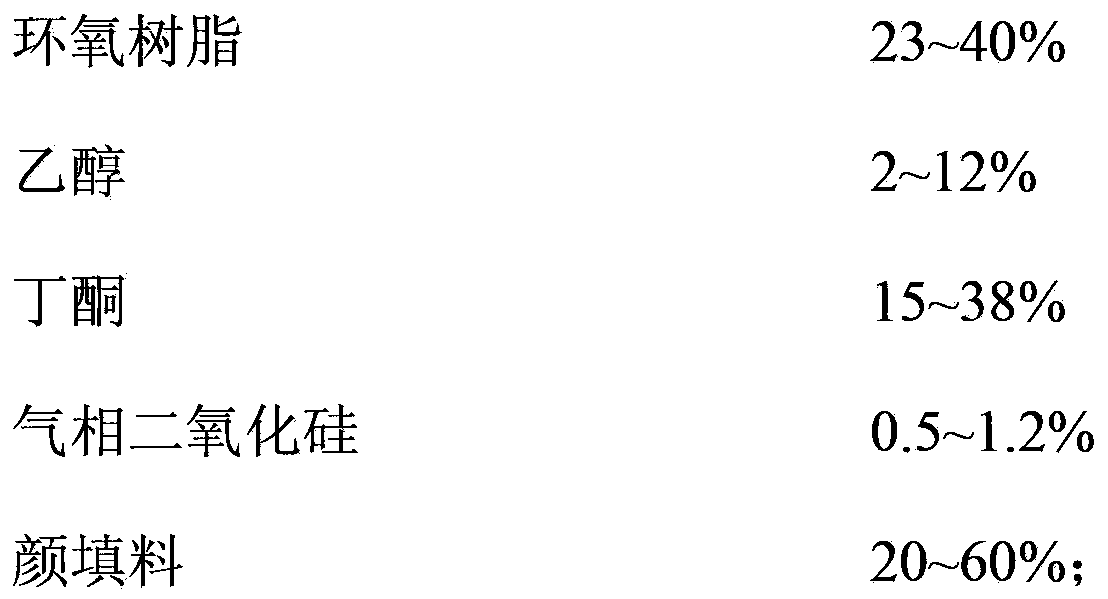

[0079] 1) The component A includes the following components by mass percentage:

[0080]

[0081] 2) The B component includes the following components by mass percentage:

[0082] Epoxy curing agent 76%

[0083] Ethanol 8%

[0084] MEK 16%.

[0085] 1) First, mix epoxy resin, methyl ethyl ketone, ethanol, pigments and fillers and additives according to the formula quantity, then disperse them, and sand them until the fineness meets the technical requirements;

[0086] 2) Filter and package the mixture obtained in step 1) to obtain component A;

[0087] 3) Pack the components A and B obtained in step 2) according to the mass ratio.

Embodiment 2

[0089] An epoxy drinking water tank coating, the coating is mainly composed of component A and component B in a mass ratio of 3:1:

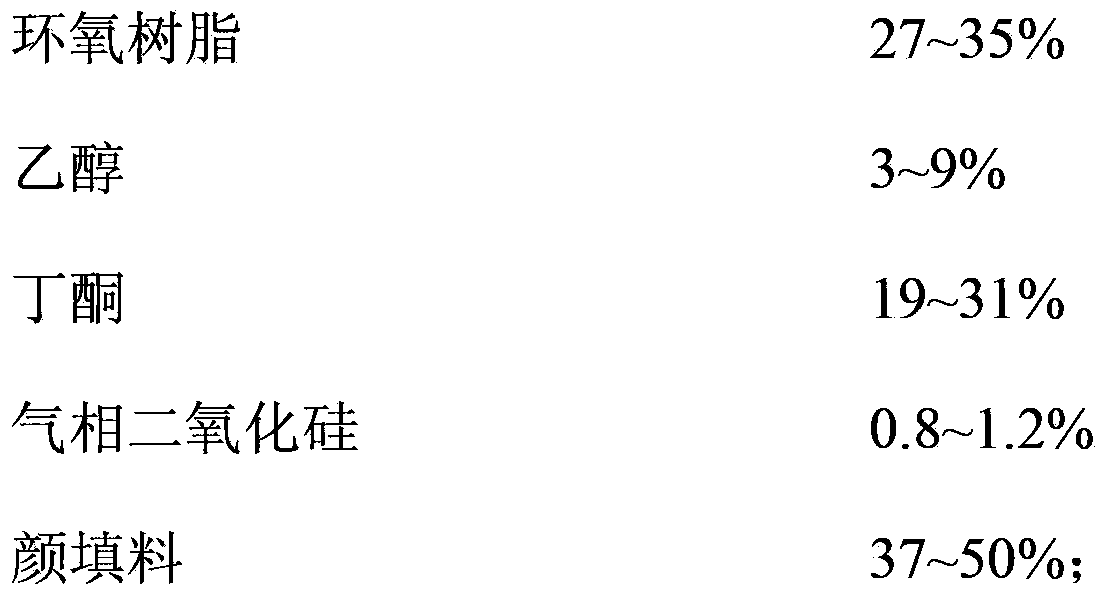

[0090] 1) The component A includes the following components by mass percentage:

[0091]

[0092] 2) The B component includes the following components by mass percentage:

[0093] Epoxy curing agent 73%

[0094] Ethanol 7%

[0095] Butanone 20%.

[0096] Its preparation method is with embodiment 1.

Embodiment 3

[0098] An epoxy drinking water tank coating, the coating is mainly composed of component A and component B in a mass ratio of 4:1:

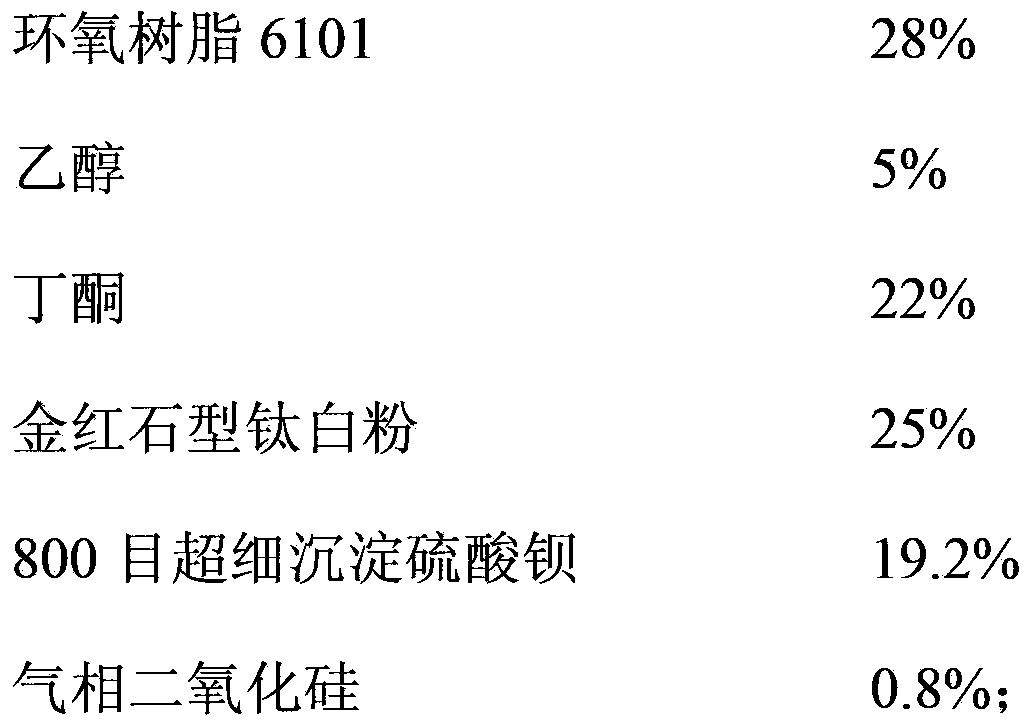

[0099] 1) The component A includes the following components by mass percentage:

[0100]

[0101] 2) The B component includes the following components by mass percentage:

[0102] Epoxy curing agent 85%

[0103] Ethanol 8%

[0104] Butanone 7%.

[0105] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com