Strain for producing L-lysine and method thereof for producing L-lysine

A lysine and strain technology, applied in the biological field, can solve the problems of residual catalyst, limited source of raw materials, poor product safety, etc., and achieve the effects of good genetic stability and increased L-lysine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

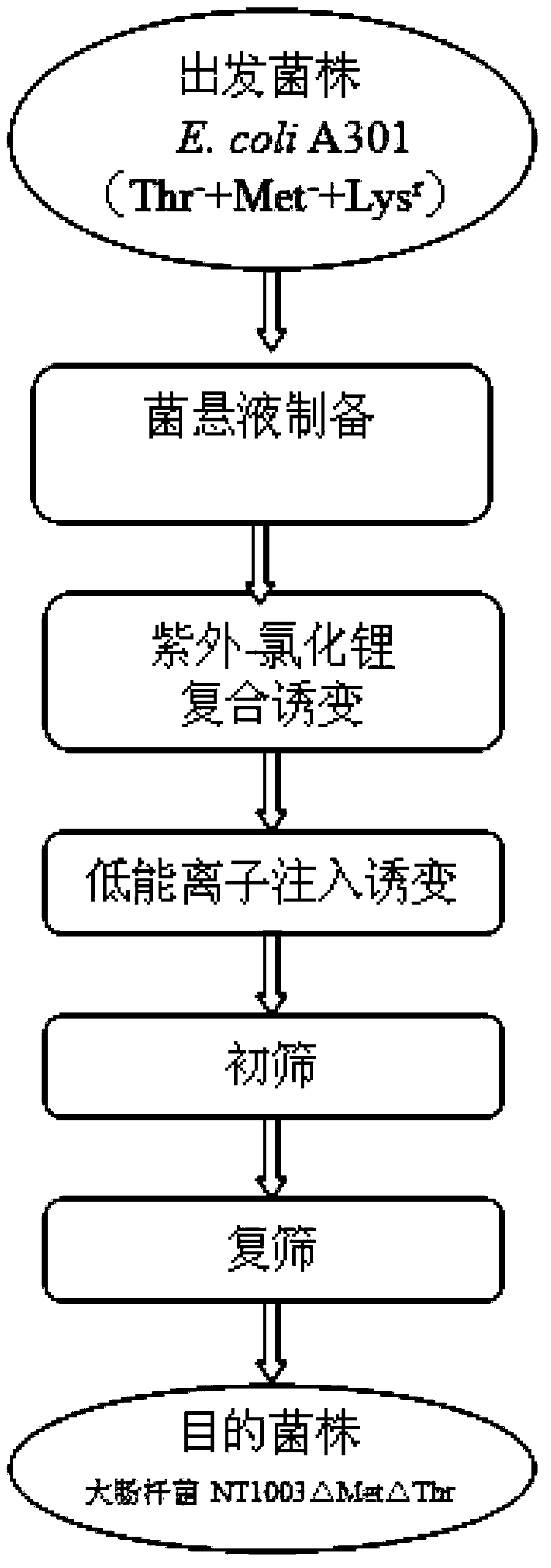

[0059] Embodiment 1: This embodiment description will E. coli A301 mutagenesis screening of Escherichia coli as a starting strain NT1003△Met△Thr Methods.

[0060] In this example:

[0061] 1) LB medium, composed of the following mass percentage components: tryptone 1%, yeast extract 0.5%, sodium chloride 1%, the rest is water, pH 6.8-7.2.

[0062] 2) Seed medium, composed of the following mass percentage components: glucose 0.05%, sucrose 0.15%, peptone 3%, yeast extract 3%, ammonium sulfate 2%, dipotassium hydrogen phosphate 0.3%, magnesium sulfate 0.1%, sulfuric acid Ferrous 0.05%, manganese sulfate 0.03%, sodium dihydrogen phosphate 0.25%, calcium carbonate 0.17%, the rest is water, pH 6.8-7.2.

[0063] 3) Fermentation medium, composed of the following mass percentage components: glucose 6%, sucrose 14%, corn steep liquor 1%, peanut cake powder 0.4%, soybean cake powder 0.4%, ammonium sulfate 0.2%, dipotassium hydrogen phosphate 0.08% , magnesium sulfate 0.02%, fe...

Embodiment 2

[0078] According to the mutagenesis screening method in Example 1, Escherichia coli NT1003ΔMetΔThr was obtained.

[0079] Among them, the amount of lithium chloride added was 3% of the mass of the LB plate medium; the ultraviolet irradiation time was 110s; the low-energy nitrogen ion implantation condition was 4 Kv / cm×3 min, and the implantation dose was 50×10 14 ions / cm 2. .

Embodiment 3

[0081] Escherichia coli NT 1003 was obtained according to the mutagenesis screening method in Example 1.

[0082] Among them, the amount of lithium chloride added was 5% of the mass of the LB plate medium; the ultraviolet irradiation time was 30s; the low-energy nitrogen ion implantation condition was 42 Kv / cm×9 min, and the implantation dose was 20×10 14 ions / cm 2. .

[0083] The morphological and physiological and biochemical characteristics of the Escherichia coli NT 1003 obtained in the above-mentioned examples 1-3 are as follows:

[0084] Colony color: off-white.

[0085] Aerobic mode: aerobic growth.

[0086] Colony size: 0.3~0.8×1~4μm.

[0087] Suitable growth temperature: 34-40°C.

[0088] Suitable growth pH: 6.8-7.2.

[0089] Bacteria morphology: round colony with metallic luster.

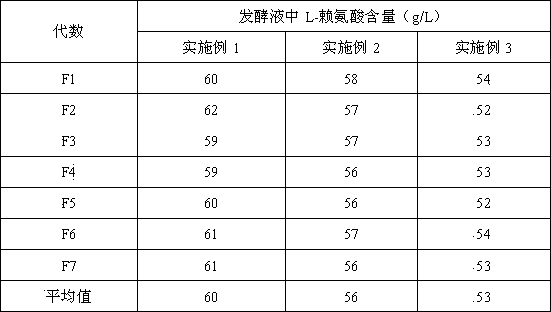

[0091] The genetic stability test of the Escherichia coli NT1003ΔMetΔThr of embodiment 1-3

[0092] In the fermentation medium with glucose and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com