Dual metal joint interface metallographic etching agent and display method

A bimetallic joint and metallographic structure technology, applied in the field of chemical analysis, can solve the problems of not being able to meet the needs of production and analysis, the severe reaction process of strong oxidants, the influence of steel-based metal structure corrosion, etc., to improve performance improvement and failure analysis The effect of inspection ability, stable and easy control of the reaction process, and simple corrosion method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method of the present invention will be described in detail below in conjunction with specific embodiments of the present invention.

[0021] to 20 # The structure of a steel-clad brass alloy (containing about 62% copper by mass percentage) layered metal composite member is taken as an example.

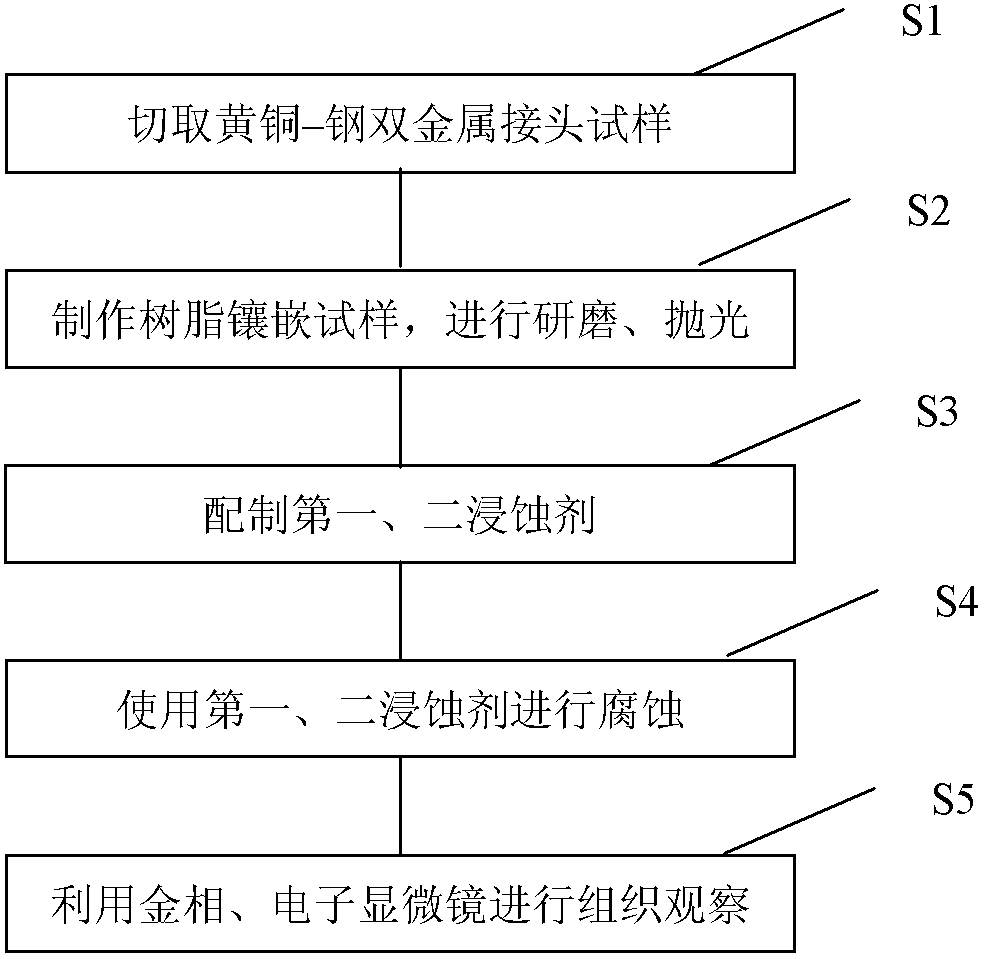

[0022] Such as figure 1 as shown,

[0023] 1 Execute step S1 to sample

[0024] First, at the joints of the components to be analyzed, use the wire cutting method that has the least impact on the interface to intercept the analysis sample with metal on both sides. The length of the sample is 10*15mm.

[0025] 2 Execute step S2 to make a metallographic sample

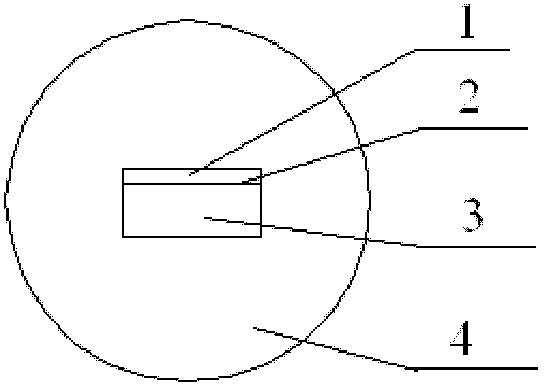

[0026] (1) Put the sample cut in step S1 into the sample mounting machine for resin mounting, and make a metallographic mounting sample with the interface transverse section as the analysis surface, and its structure is as follows figure 2 shown in .

[0027] (2) Use 500 # , 800 # 、1000 # , 1200 # Fine-grit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com