Semiconductor structure for testing an MIM (Metal-Insulating medium-Metal) capacitor

A semiconductor and capacitor technology, which is applied in the field of semiconductor structure testing of MIM capacitors, can solve the problems of difficulty in determining the relative position and detection of leakage regions in MIM capacitors, and achieves the effects of low cost, simple preparation and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

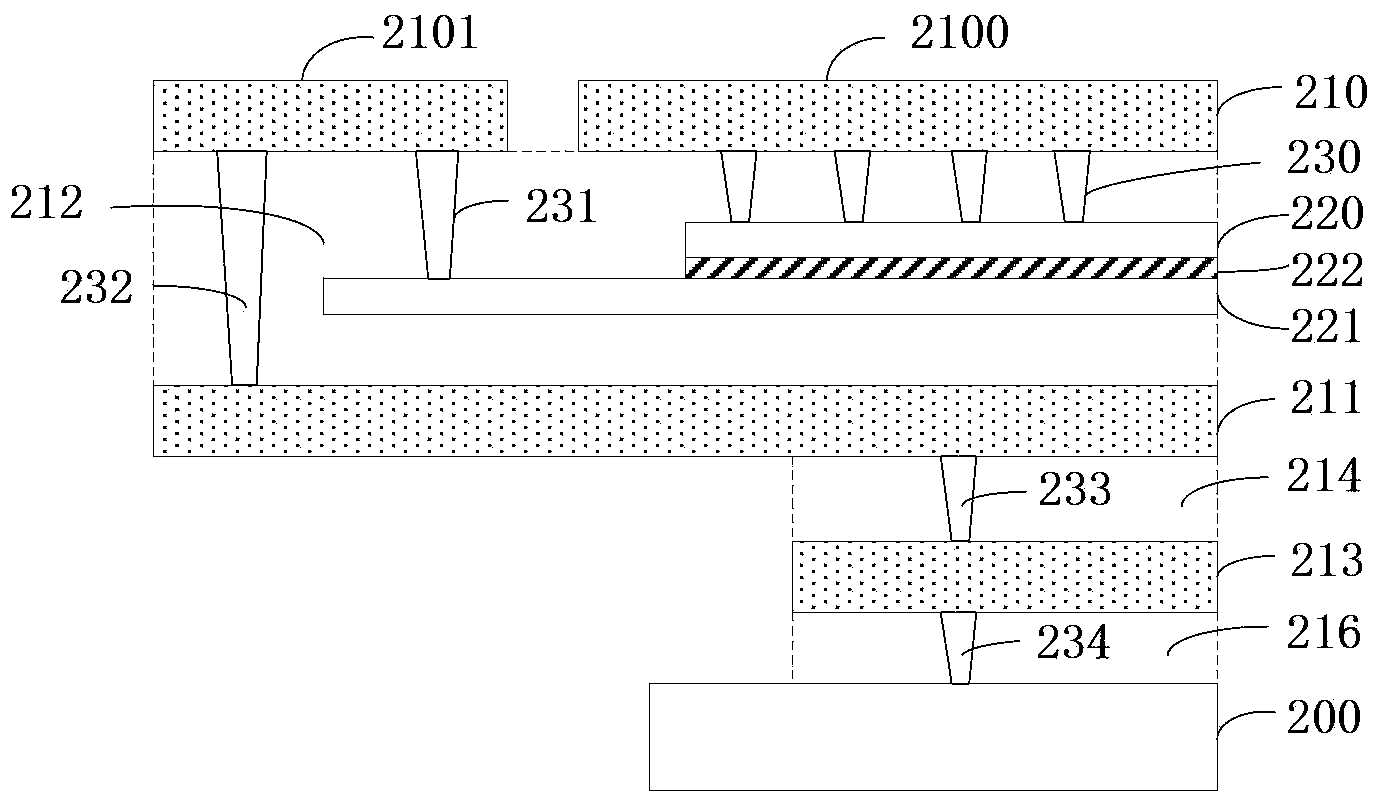

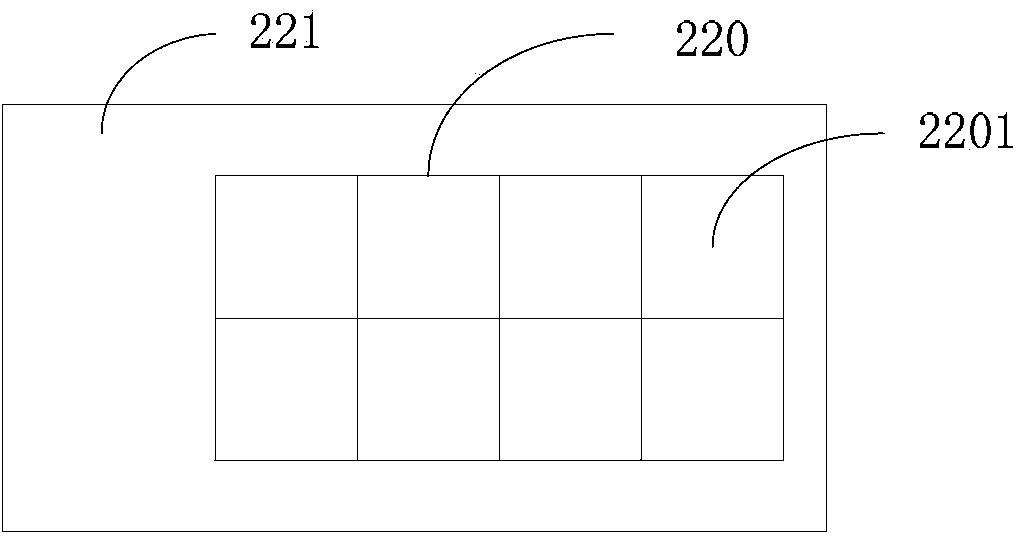

[0020] Such as figure 2 As shown, an embodiment of the present invention provides a semiconductor structure for testing MIM capacitors, including: a first metal layer 210, which can be laid on the surface of the semiconductor structure, or an internal layer of the semiconductor structure, which at least includes The first circuit area 2100 and the second circuit area 2101; the second metal layer 211, which is arranged under the first metal layer 210 with the first dielectric layer 212 as an interval, and a part of the second metal layer 211 is electrically connected to the second circuit area 2101 Connection; the upper pole plate 220 is located in the first dielectric layer 212 at a position close to the first metal layer 210, and the upper pole plate 220 is electrically connected to the first circuit area 2100; the lower pole plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com