Multilayered sheet and endless belt

A technology of endless belts and thin materials, applied in layered product processing, synthetic resin layered products, lamination, etc., can solve problems such as wear, vulnerability to damage or damage, and achieve high joint strength, efficient manufacturing, and good The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] As Example 1, Example A1-A4, Example C1-C4, and Example D1-D4 are demonstrated below.

Embodiment A1

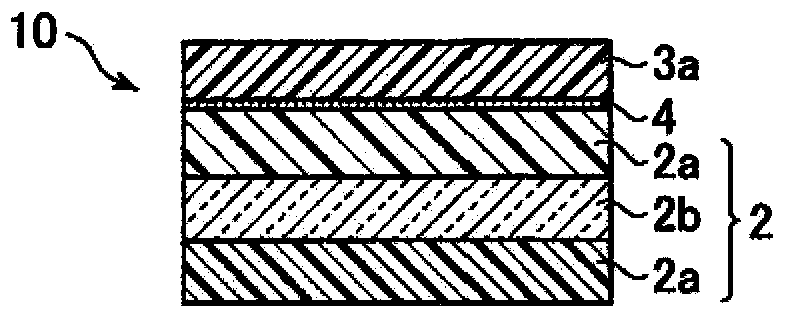

[0123] (1) A multi-layer thin material with a polyimide resin surface layer on one side of the composite material

[0124] First, in order to obtain a composite material of fluororesin and glass fiber, the aqueous suspension of fluororesin (PTFE) was impregnated and adhered to plain-woven glass fiber (thickness 95 μm) with a continuous coating device, dried at 80°C, and then Fire at 350°C to obtain a composite material (thickness 135μm) of fluororesin and glass fiber.

[0125] Next, in order to perform surface activation treatment on the composite material of fluororesin and glass fiber, 100 parts by mass of the aqueous suspension of PTFE resin was mixed with 100 parts by mass of the aqueous suspension of silica to obtain a surface activation treatment liquid.

[0126] Next, apply the surface activation treatment liquid on one side of the composite material of fluororesin and glass fiber with a continuous coating device, dry it at 80°C, and then fire it at 350°C to attach and ...

Embodiment A2

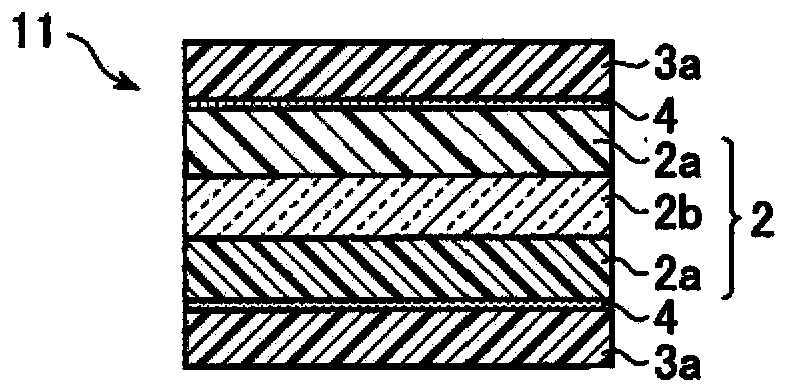

[0138] (2) A multi-layer thin material with a polyimide resin surface layer on both sides of the composite material

[0139] A multilayer thin material was obtained in the same manner as in Example A1. On the side where the polyimide resin surface layer is not formed on this multilayer sheet, perform the same operation as in Example A1 to carry out the surface activation treatment and the formation of the polyimide resin surface layer to obtain a polyimide resin Composite thin material (thickness 145μm) with surface layer on both sides of the composite material ( figure 2 ).

[0140] The structure of Example A2 is preferably used in applications where wear resistance and anti-slip properties are important, but not adhesion, but it is not limited thereto.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com