Modified wet curtain paper, air purification assembly and air conditioner

A technology of air purification and wet curtain paper, which is applied in air-conditioning systems, air quality improvement, cardboard products, etc. It can solve the problems of additives and glue failure, accelerate the aging of wet curtain paper, and low sterilization efficiency, etc. It is easy to achieve functional upgrades , low cost, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

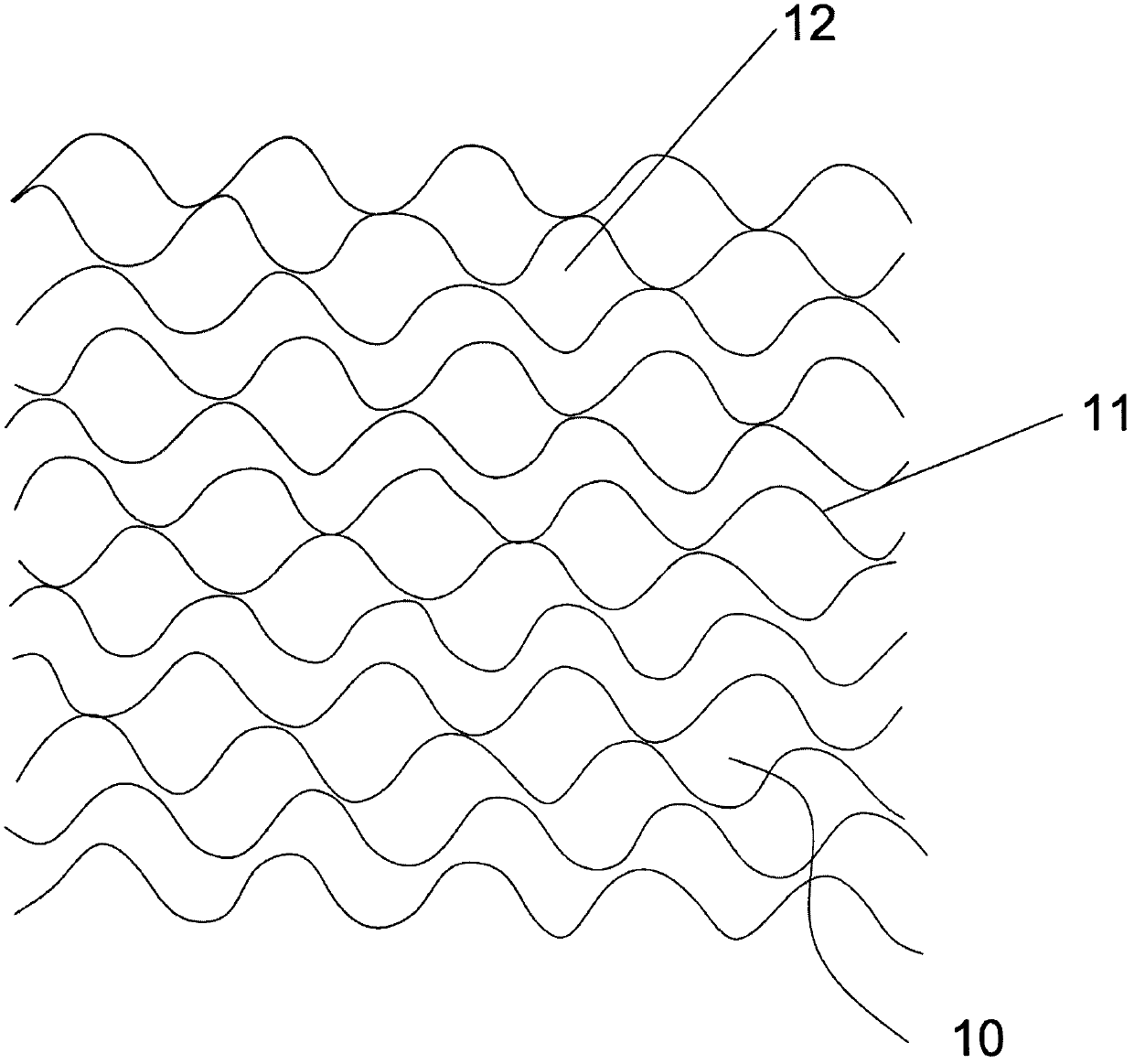

[0032] Such as figure 1 As shown, this embodiment provides a modified wet curtain paper 10, the wet curtain paper includes a plurality of stacked corrugated sheets 11, adjacent corrugated sheets are interlaced to form a wall-shaped body with honeycomb holes 12, which It is characterized in that the corrugated sheet 11 includes a core layer, and the core layer is a paper layer. The paper in this embodiment refers to dissociation of plant fiber raw materials into pulp by mechanical means, chemical means or a combination of both. Then the paper obtained by drying and dehydrating is coated with a layer of inorganic adsorption material on the surface of the paper core layer, and the surface of the inorganic adsorption material is also sprayed with nano-scale photocatalyst material. The inorganic adsorption material includes: attapulgite powder, clay, mica powder, molecular sieve, calcium carbonate, talcum powder, flame retardant (aluminum hydroxide), diatomaceous earth, cellulose, ...

Embodiment 2

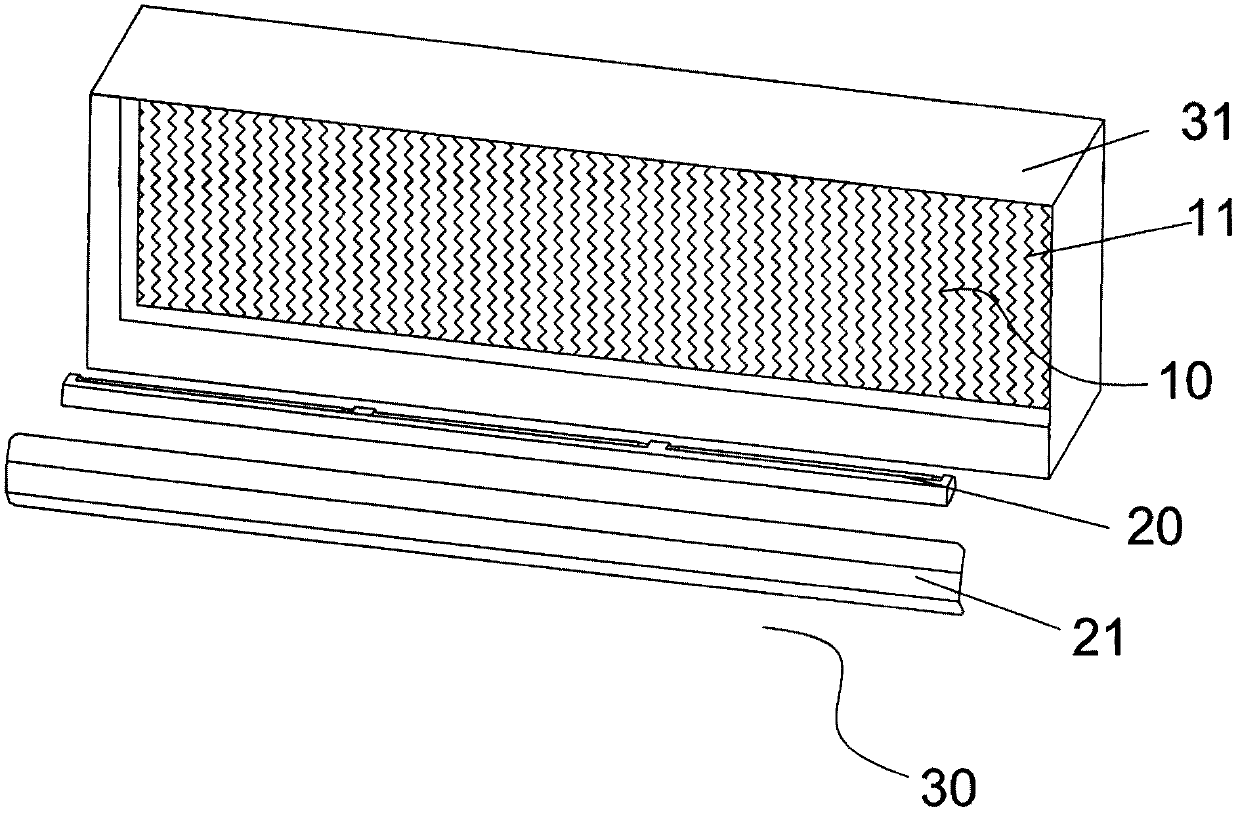

[0059] This embodiment provides an air cleaning assembly 30, such as Figure 2-3 As shown, the air purification assembly includes the modified wet curtain paper 10 described in Embodiment 1, and the air purification assembly also includes an ultraviolet lamp tube 20, and the ultraviolet lamp is arranged on the side of the modified wet curtain paper. The ultraviolet light tube is parallel to the side of the modified wet curtain paper in the shape of a plane wall, and the arrangement and direction of the ultraviolet light tube and the corrugated sheet 11 are vertical, so that the ultraviolet light of the ultraviolet light tube can irradiate more honeycomb holes on the surface . The vertical distance between the ultraviolet lamp tube and the side of the modified wet curtain paper is 2 to 10 cm, and a reflector 21 is arranged outside the ultraviolet lamp tube for reflecting the ultraviolet light emitted by the ultraviolet lamp tube 20 to the wet curtain paper 10, the wet curtain pa...

Embodiment 3

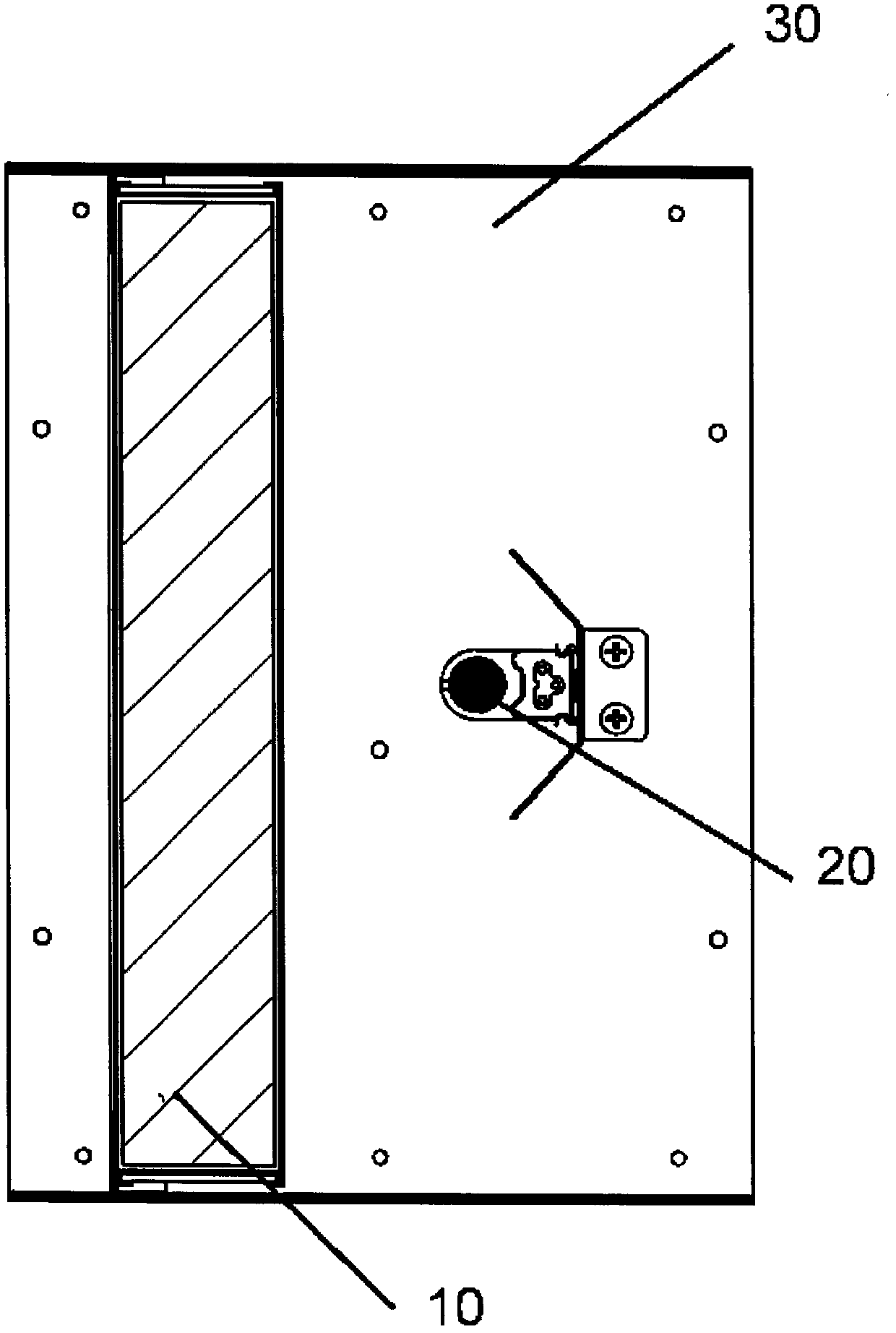

[0061] This embodiment provides an air purification assembly different from that of Embodiment 2. When the area of the modified wet curtain paper is large, and the required modified wet curtain paper is thick, such as Figure 4-5 As shown, the air purification assembly includes two modified wet curtain papers 10 as described in Example 1 and three ultraviolet lamp tubes, and the two modified wet curtain papers 10 are arranged in parallel and opposite to each other, with a distance of 4 to 4. 20cm, three ultraviolet lamp tubes 20 are set between two modified wet curtain papers 10, and the three ultraviolet lamp tubes are all parallel to the two modified wet curtain papers 10, and the three ultraviolet lamp tubes 20 are parallel to each other and The spacing is equal, and the distance between the three ultraviolet lamps and the two modified wet curtain papers is the same. As in Example 2, each ultraviolet lamp is arranged perpendicular to the corrugated 11 of the corrugated she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com