Preparation method and application of hyperbranched polyester

A hyperbranched polyester and reaction technology, applied in the field of polymer materials, can solve the problems of irreversible destruction of enzymes, slow enzymatic catalysis reaction, limited use, etc., and achieve the effects of improving melting index, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

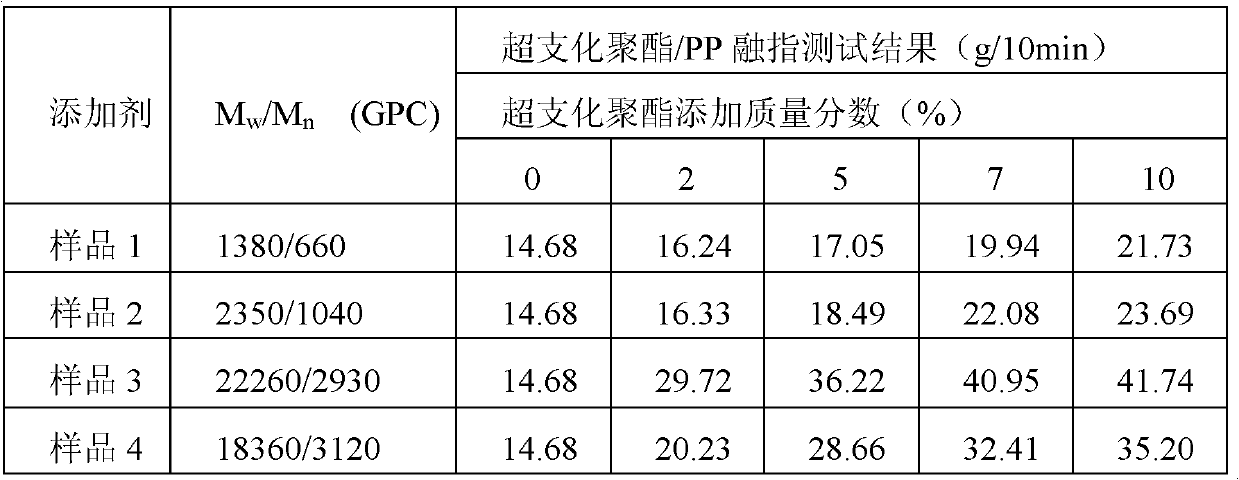

Embodiment 1

[0030] Preparation of hyperbranched polyester from oxalic acid and glycerin

[0031] Under solvent-free conditions, weigh 0.55mol of oxalic acid and 0.55mol of glycerol in a molar ratio of 1:1 into a 250mL four-necked flask equipped with a stirrer, thermocouple, nitrogen gas inlet pipe, and Claisen condenser . Under nitrogen flow, the flow rate is 40mL / min, after replacing the air 3 times, add 0.1wt% dibutyltin oxide of the total amount of oxalic acid and glycerin, and heat the oil bath to 80℃ for 2h; reaction process In the process, the flowing gas method is used to separate the water generated during the reaction, that is, to maintain a flow of nitrogen gas at 150 mL / min to separate the water generated during the reaction; after the reaction, cool to room temperature to obtain a transparent and viscous reaction product, that is, the sample 1.

[0032] Measure the M of product sample 1 w 1380, M n Is 660.

Embodiment 2

[0034] Preparation of hyperbranched polyester from succinic acid and trimethylolethane

[0035] Under the condition of solvent-free, weigh according to the molar ratio of 1.5:1, 0.51mol of succinic acid and 0.34mol of trimethylolethane are added to the mixer, thermocouple, nitrogen gas inlet pipe, and Claisen condenser 250mL four-necked flask. Under nitrogen flow, the flow rate is 40mL / min, after replacing the air twice, add 0.2wt% dibutyltin dilaurate of the total amount of succinic acid and trimethylolethane, and heat to 100℃ in an oil bath , The reaction is carried out for 3h; during the reaction, the flow gas method is used to separate the water generated in the reaction, that is, keep the nitrogen gas flowing at 200mL / min to separate the water generated in the reaction; after the reaction, cool to room temperature to obtain a transparent, Viscous reaction product, sample 2.

[0036] The Mw of the product sample 2 was measured to be 2,350, and the Mn was 1,040.

Embodiment 3

[0038] Preparation of Hyperbranched Polyester from Adipic Acid and Glycerin

[0039] Under solvent-free conditions, weigh 0.52mol of adipic acid and 0.26mol of glycerol in a molar ratio of 2:1 into a 250mL four-necked flask equipped with a stirrer, thermocouple, nitrogen gas inlet pipe, and Claisen condenser . Under nitrogen flow, the flow rate is 80mL / min. After replacing the air 3 times, add 3wt% dibutyltin dilaurate of the total amount of adipic acid and glycerin, and heat to 150℃ in an oil bath, and react for 8h. , The water produced by the reaction was separated by a reduced pressure method, and the water formed in the reaction was separated by applying a reduced pressure of 150 mbar; after the reaction was completed, cooled to room temperature to obtain a transparent and viscous reaction product, namely sample 3.

[0040] Measure the M of product sample 3 w 22260, M n For 2930.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com