A kind of silicon negative electrode lithium-ion battery and manufacturing method thereof

A lithium-ion battery and manufacturing method technology, applied in electrolyte battery manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as low specific capacity and short cycle life, and achieve high battery energy density, excellent charge-discharge performance, and low price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

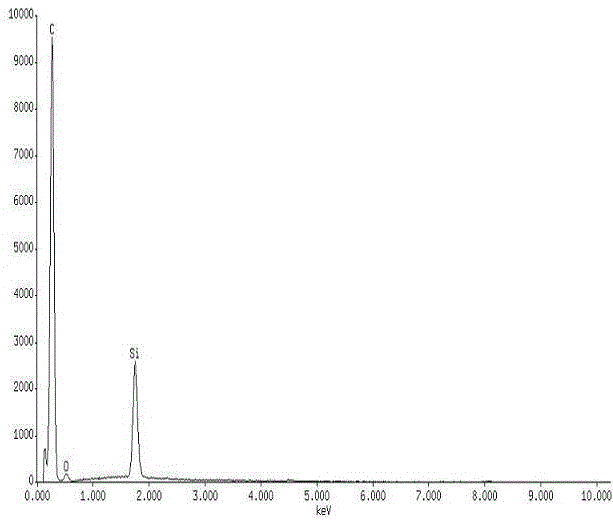

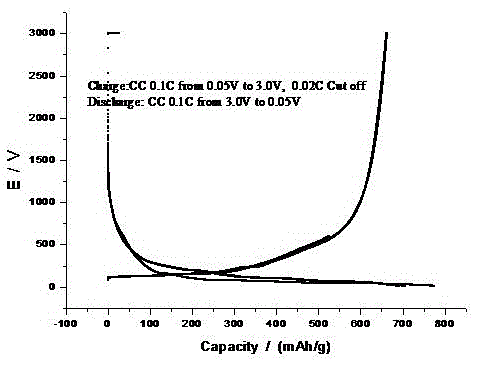

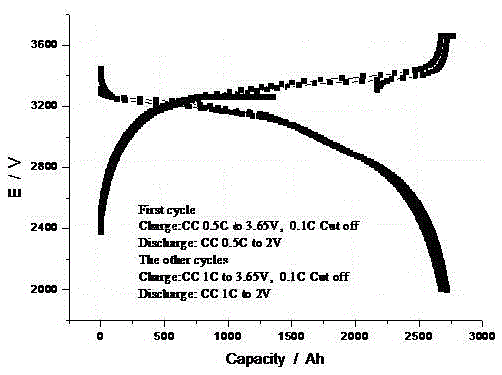

Embodiment 1

[0031] A lithium-ion battery with a silicon negative electrode, comprising a positive electrode, a negative electrode, and a separator located between the positive and negative electrodes. The lithium-ion battery with a silicon negative electrode has a laminated structure. The negative electrode is composed of a current collector, an active material, a conductive agent, and a binder. The active material is a silicon-carbon composite material coated with a carbon layer, and the carbon layer is formed by pyrolysis of glucose or sucrose. The active substance is prepared through the following steps:

[0032] Step a) Ball milling: 1500g natural graphite powder and 500g silicon powder with a particle size of 40 microns are mechanically high-energy ball milled in an argon atmosphere for 8 hours at a speed of 100 rpm to prepare a silicon-carbon composite material. Among them, the natural graphite powder is compacted The density is 0.96g / c㎡;

[0033] Step b) Dissolving and stirring: Dissol...

Embodiment 2

[0040] A lithium ion battery with a silicon negative electrode, comprising a positive electrode, a negative electrode, and a separator between the positive and negative electrodes. The lithium-ion battery with a silicon negative electrode has a laminated structure. The negative electrode is composed of a current collector, an active material, a conductive agent and a binder. The active material is a silicon-carbon composite material coated with a carbon layer, and the carbon layer is formed by pyrolysis of glucose or sucrose.

[0041] The active substance is prepared through the following steps:

[0042] Step a) Ball milling: 2500g natural graphite powder and 500g silicon powder with a particle size of 50 microns are mechanically high-energy ball milled in an argon atmosphere for 8-10 hours at a speed of 400 rpm to obtain a silicon-carbon composite material. The tap density is 0.96g / c㎡;

[0043] Step b) Dissolving and stirring: Dissolve 400g of glucose in 3000g of distilled water, a...

Embodiment 3

[0049] A lithium ion battery with a silicon negative electrode, comprising a positive electrode, a negative electrode, and a separator between the positive and negative electrodes. The lithium-ion battery with a silicon negative electrode has a laminated structure. The negative electrode is composed of a current collector, an active material, a conductive agent and a binder. The active material is a silicon-carbon composite material coated with a carbon layer, and the carbon layer is formed by pyrolysis of glucose or sucrose. The active substance is prepared through the following steps:

[0050] Step a) Ball milling: 4,500 natural graphite powder and 500g silicon powder with a particle size of 30 microns are mechanically high-energy ball milled in an argon atmosphere for 10 hours to obtain a silicon-carbon composite material, wherein the tap density of the natural graphite powder is 0.96g / c㎡;

[0051] Step b) Dissolving and stirring: Dissolve 500g of sucrose in 5000g of distilled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com