Bypass purification system for treating slightly polluted river water

A purification treatment, cement technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of lax management of sewage discharge and sudden drop in the sewage capacity of rivers, etc. Achieve the effects of preventing short water areas and dead water areas, cheap performance, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

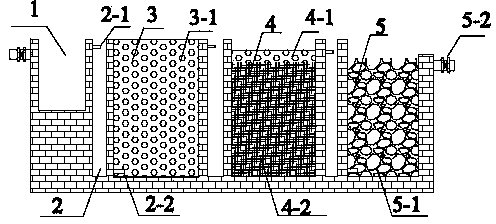

[0030] Embodiment 1: The outlet water of the sedimentation tank 1 enters the nitrification section 3 through the inlet pipe 2-1 through the corridor 2 and the bottom inlet pipe 2-2; the water flows through the filler 3-1, passes through the top of the nitrification section 3, and enters the denitrification through the corridor The bottom of the denitrification section enters the denitrification section 4; the water is discharged from the top of the denitrification section 4 through the packing 4-2 and 4-1, and enters the bottom of the adsorption phosphorus removal section through the corridor, and then enters the adsorption phosphorus removal section 5; the phosphorus removal is carried out through the packing 5-1 Finally, it is discharged through the outlet pipe 5-2.

specific Embodiment approach 2

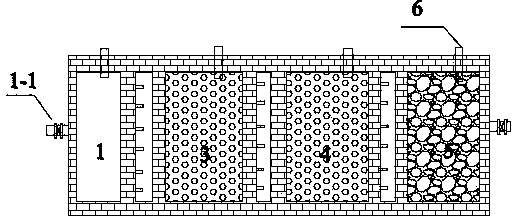

[0031] Specific implementation mode two: combination figure 1 and figure 2To illustrate this embodiment, the patent of the invention includes nitrification section, denitrification section and adsorption dephosphorization section, and the fillers in the nitrification section are all filled with zeolite; the denitrification filler layer includes an upper layer and a lower layer, that is, a zeolite layer and a slow-release carbon source (rotting wood) layer , the upper layer is a zeolite layer, the particle size range is 5-10mm, and the lower layer is rotten wood chips cut from rotten wood; the adsorption and phosphorus removal section is all filled with cement bricks, and the particle size range is 5cm.

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 and figure 2 This embodiment is described. In this embodiment, deflectors are arranged between each section to form a water inlet corridor, thereby realizing an upward water inlet mode. The water entering the sedimentation tank 1 enters the nitrification section 3 through the corridor 2, and each section enters and exits the water through a similar cycle, which effectively reduces the hydraulic dead zone of each section and ensures a good hydraulic flow state inside the system. Other components and connections are the same as those in the first embodiment.

[0033] Specific implementation mode four: combination figure 1 and figure 2 Describe this embodiment, this embodiment fills packing in nitrification section 3, denitrification section 4 and adsorption dephosphorization section 5, and the filler of nitrification section 3 is the zeolite with good ammonia nitrogen adsorption capacity, and the filler of adso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com