Method for preparing photocatalyst with visible light response by mechanochemical treatment on polybrominated diphenyl ether solid waste

A polybrominated diphenyl ether, mechanochemical technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. Consumption and operating costs, low energy consumption, saving raw materials and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

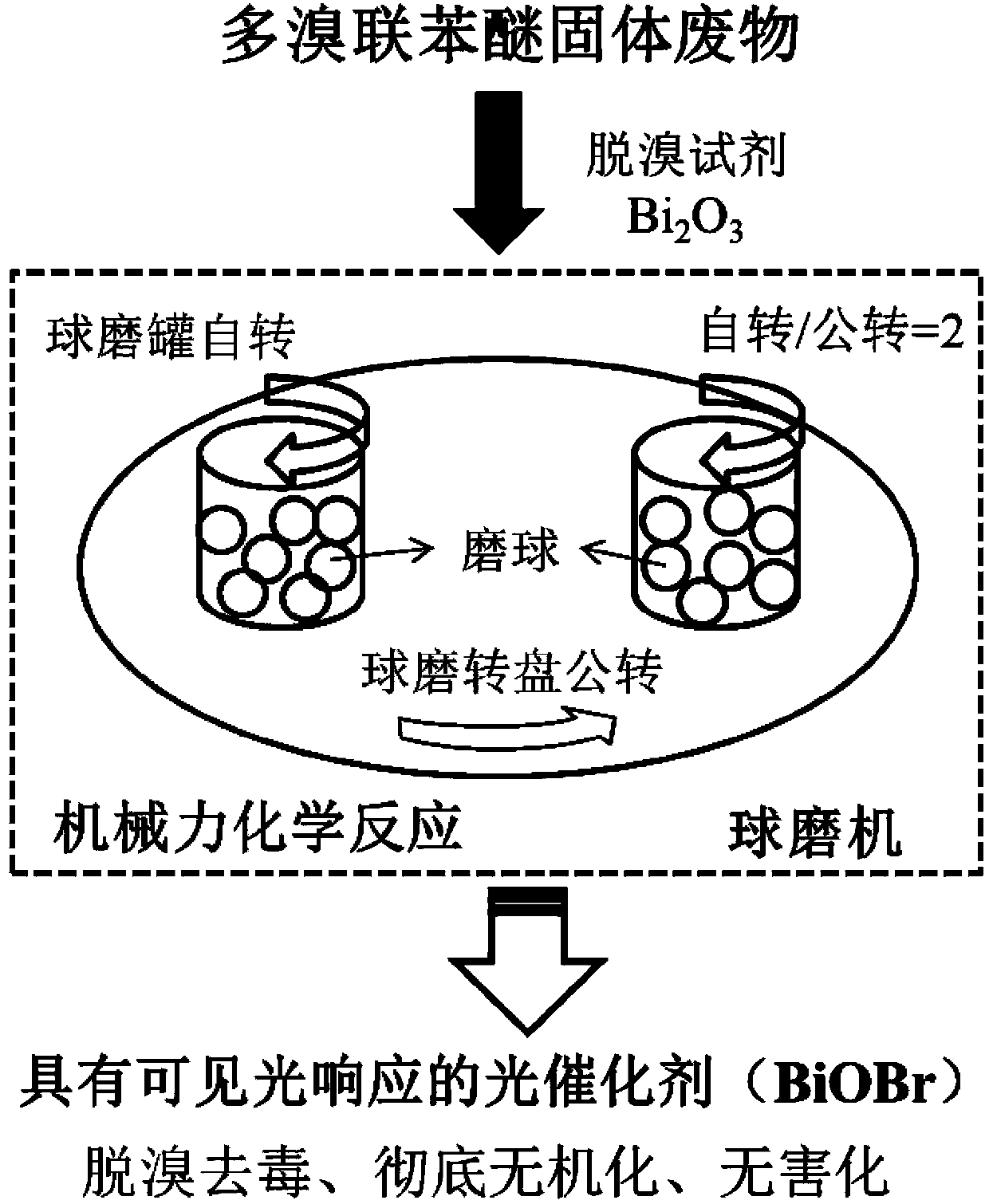

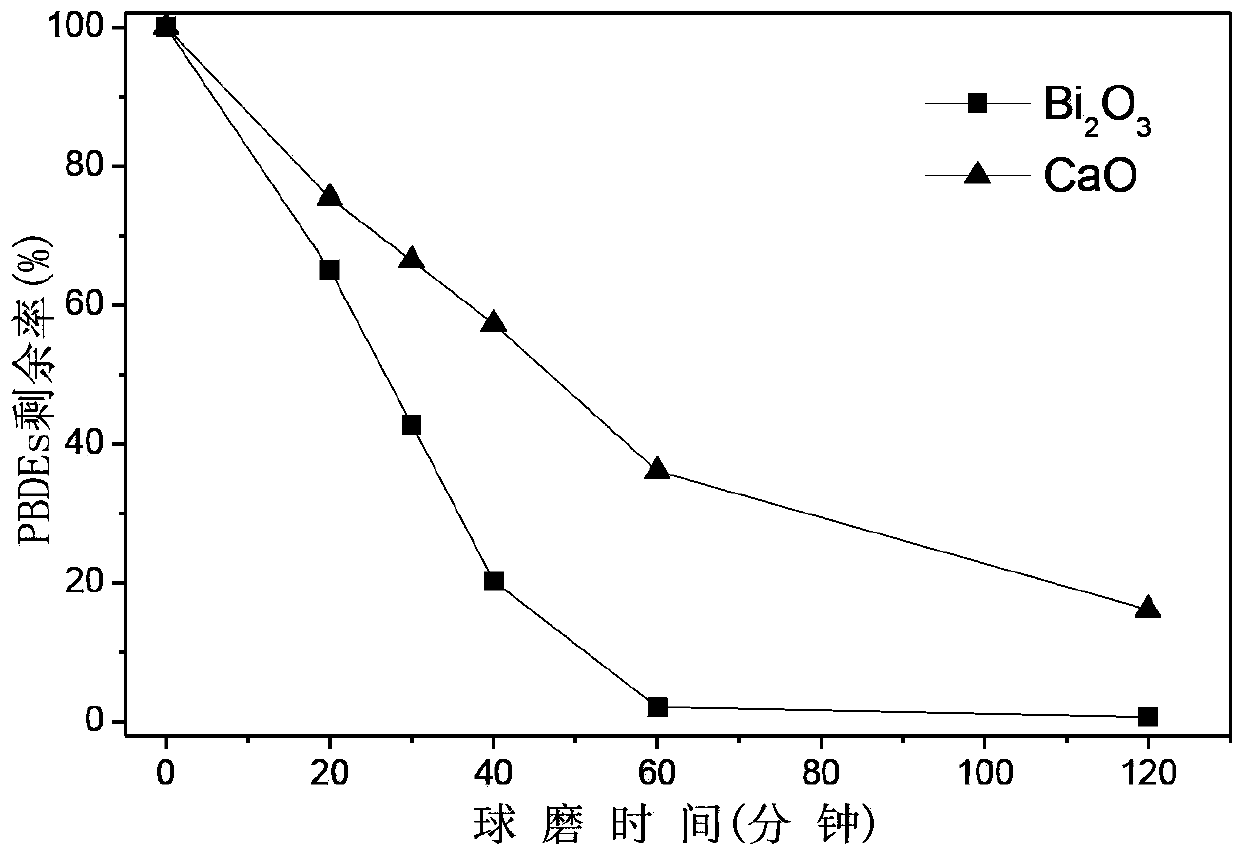

[0030] In order to explore Bi 2 o 3 As a ball milling additive, the degradation effect of PBDEs in the ball milling process was tested using traditional ball milling reagents CaO and Bi 2 o 3 Compare under the same material ratio (i.e. the mass ratio of debromination reagent to PBDEs), according to figure 1The schematic flow chart shown was used to conduct a control experiment. In this experiment, PBDEs were represented by commercial decabromodiphenyl ether.

[0031] The debrominated reagent Bi 2 o 3 Or CaO and decabromodiphenyl ether according to the same material ratio (2.125g debromination reagent: 0.875g decabromodiphenyl ether, a total of 3.0g, to ensure that the molar ratio of Bi:Br is 1:1) into the ball mill tank , and then add 7 balls (diameter 15mm, average weight 10.5g) into the ball mill jar. The inner diameter of a single ball milling jar is 40mm, the effective volume is 50mL, and the space between the ball milling jar and the lid is sealed with a polytetraf...

Embodiment 2

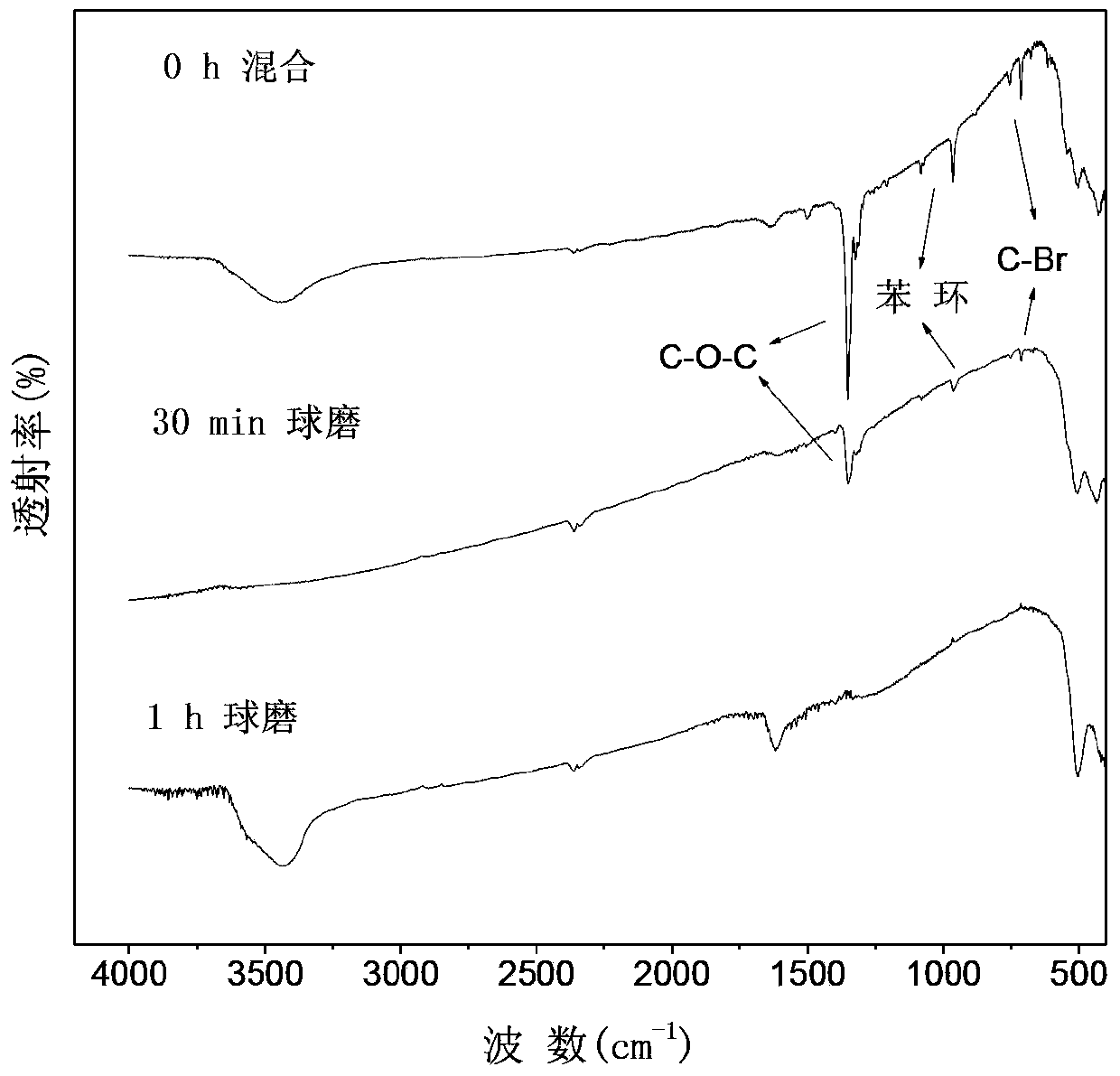

[0034] In order to show the change situation of PBDEs in the solid sample more specifically when ball milling reaction, adopt and utilize Bi in embodiment 1 2 o 3 The same sample (0h mixing, 0.5h ball milling and 1h ball milling) used as an additive to mechanochemically degrade decabromodiphenyl ether was analyzed by Fourier transform infrared spectroscopy (FTIR). image 3 shown.

[0035] For Bi 2 o 3 Compared with the 0h mixture of decabromodiphenyl ether without ball milling, the sample has three obvious absorptions in the FTIR spectrum: at 1350cm -1 There is a strong absorption peak on the left and right, which comes from the stretching vibration of the aromatic ether bond C-O-C in decabromodiphenyl ether; the other is at 960cm -1 The left and right absorption peaks come from the stretching vibration of the substituted benzene ring in the decabromodiphenyl ether molecule; while at 500-700cm -1 The left and right absorption bands are derived from the stretching vibratio...

Embodiment 3

[0037] In order to identify the change of the reactant and the generation of the final product in the ball milling process, similar to Example 2, using Bi 2 o 3 The same sample (0h mixing, 0.5h ball milling and 1h ball milling) used as an additive to mechanochemically degrade decabromodiphenyl ether was analyzed by X-ray diffraction (XRD). The obtained results are as follows Figure 4 shown.

[0038] After searching the XRD pattern card library, it can be seen that for Bi 2 o 3 Compared with the 0h mixture of decabromodiphenyl ether without ball milling, its XRD diffraction peak mainly comes from Bi 2 o 3 (Such as Figure 4 shown in ●), decabromodiphenyl ether also has some irregular small diffraction peaks around 20-25° (such as Figure 4 Indicated by ○ in). After 30min of ball milling, the diffraction peaks from decabromodiphenyl ether almost disappeared, Bi 2 o 3 The intensity of the diffraction peaks also decreased significantly, and at the same time, a diffractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com