A kind of preparation method of ferrous chelating antimicrobial peptide

An antibacterial peptide and chelation technology, applied in the field of preparation of ferrous chelated antibacterial peptides, can solve the problems of high price and large side effects, and achieve the effects of convenient operation, large-scale deep processing, and abundant scraps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

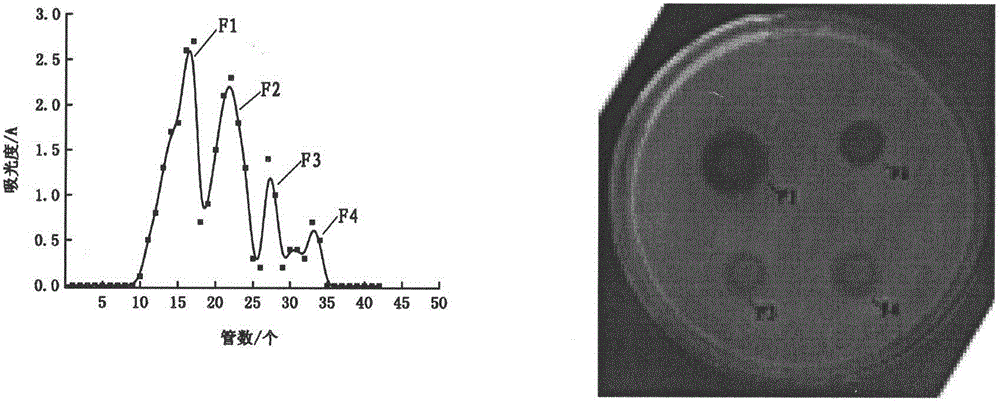

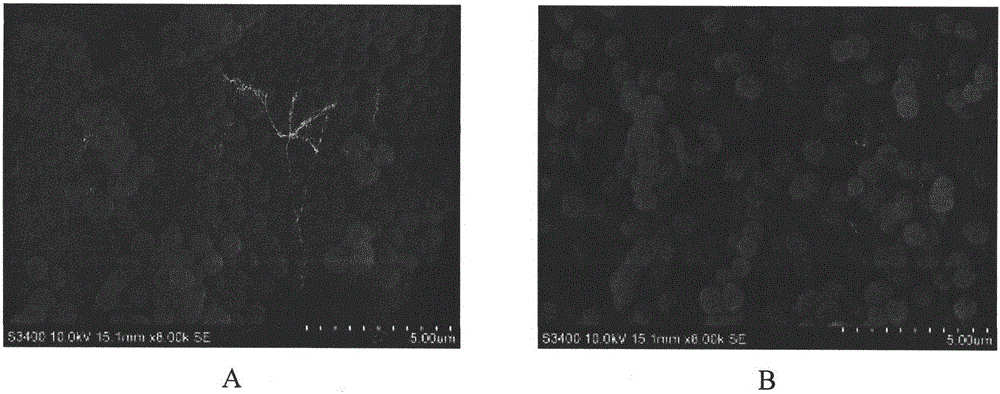

[0021] Embodiment 1 Preparation of hairtail enzymolysis protein ferrous chelating antimicrobial peptide

[0022] 1. The hairtail leftovers are crushed by a minced meat grinder, take 10g and add distilled water 100mL, then add 200mg into papain, carry out enzymatic hydrolysis at 40°C for 8-10h, heat to 90-100°C, inactivate the enzyme for 10-20min, 3000g After centrifuging for 10 min, filter the surface oil with filter paper, and then filter the precipitate.

[0023] 2. Add ferrous chloride to the enzymolysis solution, the ratio of ferrous chloride to the enzymolysis solution by volume is 1-30:40 (mg:mL), shake and chelate for 30-50°C at 30-50°C After 60 minutes, centrifuge and remove the precipitate to become the crude extract of hairtail enzymolyzed protein ferrous chelated antimicrobial peptide.

[0024] 3. Vacuum concentrate the crude extract of hairtail enzymatic protein ferrous chelated antibacterial peptide, concentrate at 40°C for 8 hours; freeze-dry the concentrate at ...

Embodiment 2

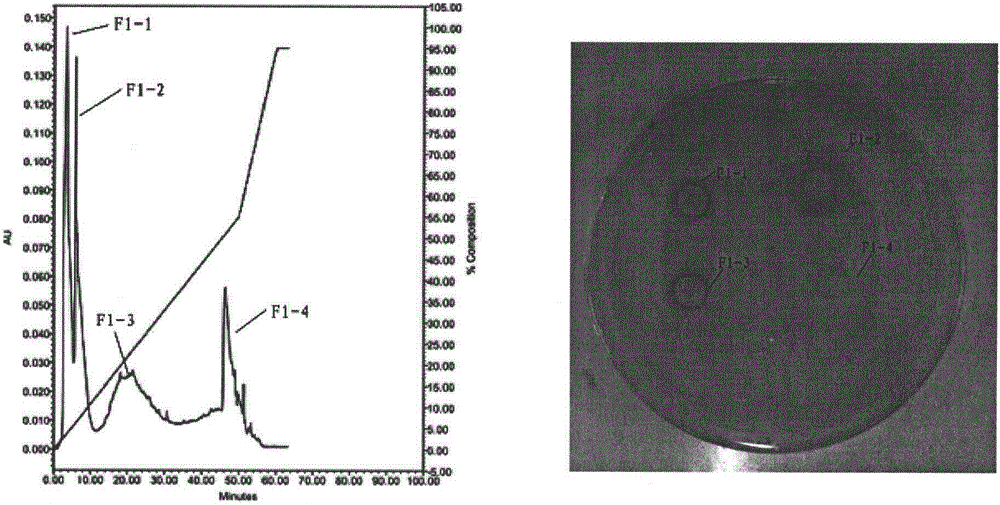

[0029] Antibacterial experiment of embodiment 2 hairtail enzymolysis protein ferrous chelating antimicrobial peptide

[0030] Using the Oxford cup method, the antibacterial activity experiment was carried out on the hairtail enzymatic protein ferrous chelating antimicrobial peptide of Example 1. The bacteria was Staphylococcus aureus ATCC25923.

[0031] The minimum inhibitory concentration of hairtail enzymatic protein ferrous chelated antimicrobial peptide against Staphylococcus aureus is shown in Table 1, and the results of minimum bactericidal concentration are shown in Table 2.

[0032] Table 1 Minimum inhibitory concentration of ferrous chelated antimicrobial peptides from hairtail enzymatic protein

[0033]

[0034] Note: "+" means colony growth, "-" means no colony growth;

[0035] Table 2 Minimum bactericidal concentration of ferrous chelated antimicrobial peptides from hairtail enzymatic protein

[0036]

[0037] Note: "+" means there is colony growth, "-" me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com