Preparation method for cladding lithium cobaltoxide cathode material with alumina

A technology of coating lithium cobaltate and positive electrode materials, which is applied to battery electrodes, electrical components, circuits, etc., can solve the problems of cumbersome filtration and washing steps, rising costs, and high electrochemical capacity, so as to achieve easy and convenient raw material composition and product formulation. The effect of reducing preparation cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

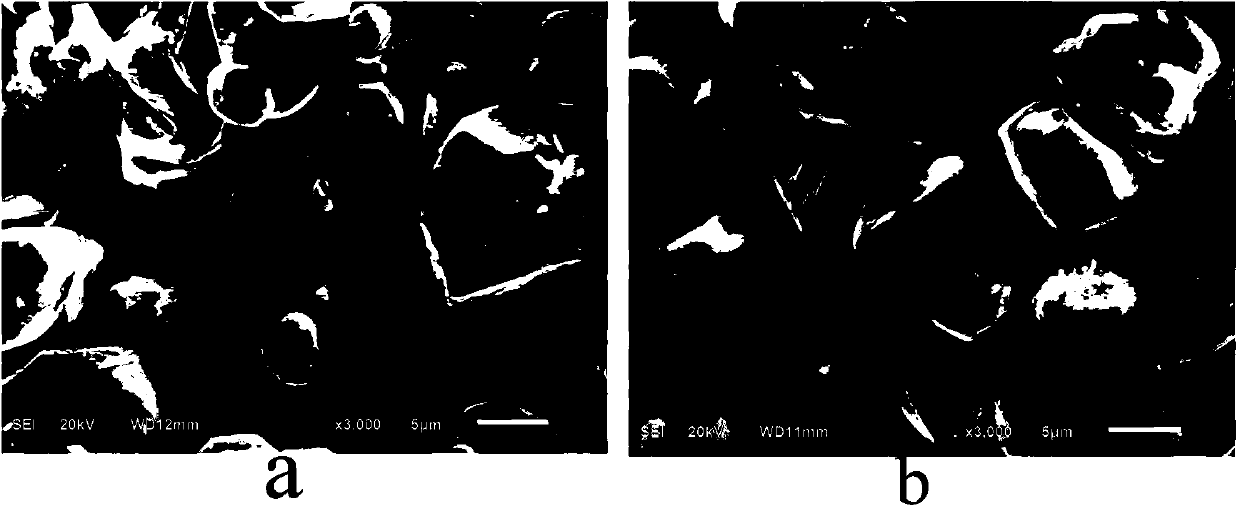

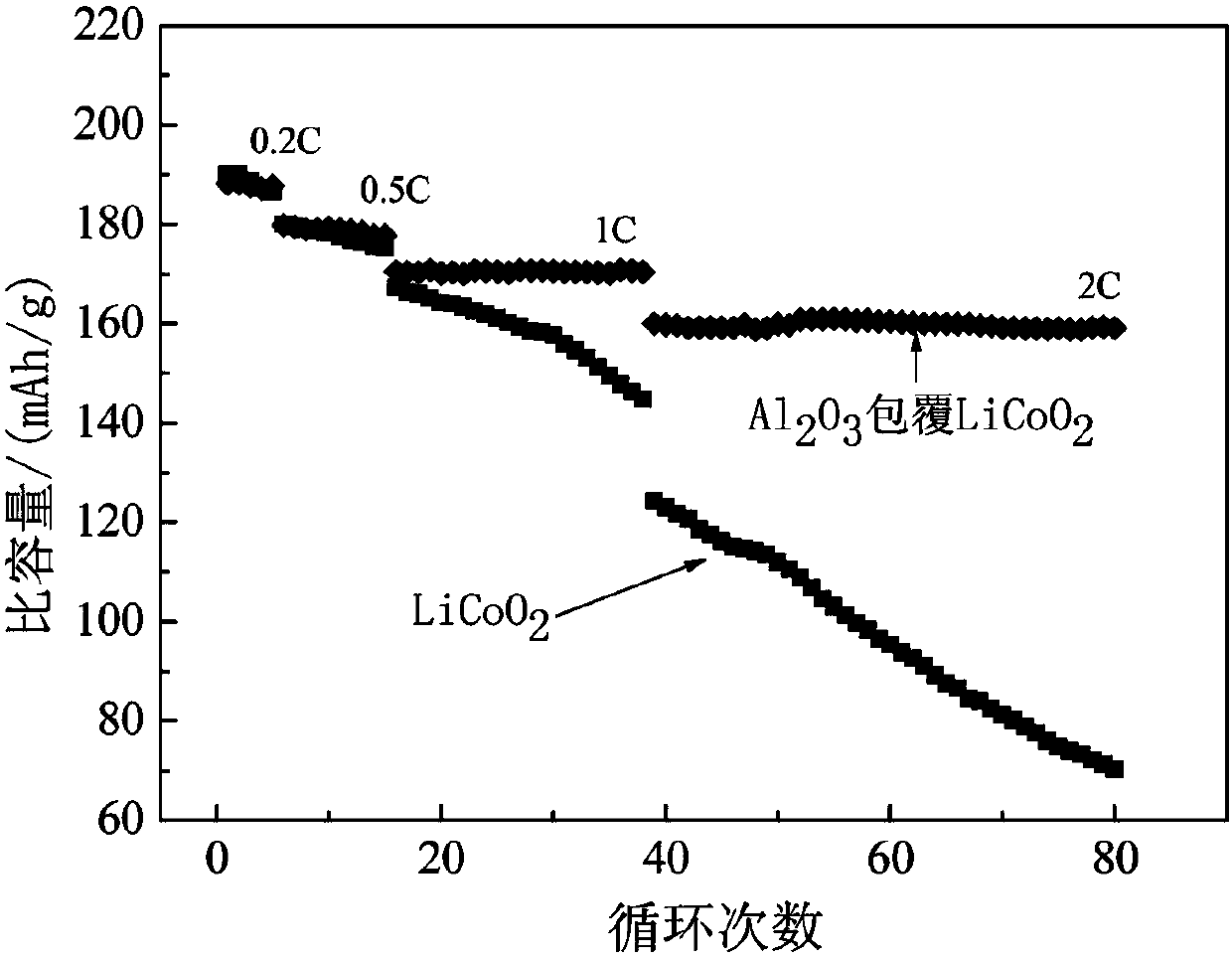

[0016] Mix lithium cobaltate and aluminum isopropoxide, wherein the molar ratio of aluminum isopropoxide to lithium cobaltate is 1:50, ball mill for 20 hours to obtain a uniformly mixed powder, heat-treat the above mixed material at 300°C for 2 hours, Then, it was cooled to room temperature at a cooling rate of 20° C. / min to prepare an aluminum oxide-coated lithium cobalt oxide cathode material.

Embodiment 2

[0018] Mix lithium cobaltate and aluminum ethoxide, wherein the molar ratio of aluminum isopropoxide to lithium cobaltate is 1:200, ball mill for 6 hours to obtain a uniformly mixed powder, heat-treat the above mixed material at 300°C for 2 hours, and then Cool down to room temperature at a cooling rate of 10°C / min to prepare an alumina-coated lithium cobalt oxide cathode material.

Embodiment 3

[0020] Mix lithium cobaltate and aluminum acetylacetonate, wherein the molar ratio of aluminum isopropoxide to lithium cobaltate is 1:50, ball mill for 20 hours to obtain a uniformly mixed powder, heat-treat the above mixed material at 600°C for 2 hours, and then Cool to room temperature at a cooling rate of 20°C / min to prepare an alumina-coated lithium cobalt oxide cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com