New zwitter-ionic polymer containing multiple phosphonic acid end groups, preparation method and application thereof

A zwitterionic and polymer technology, applied in the field of zwitterionic polymers, can solve the problems of complex surface modification methods, difficult to find groups, etc., to achieve excellent anti-bacterial adhesion ability and surface lubrication ability, low concentration requirements, modified layer stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Functional Self-Assembly of Titanium Oxide Surface

[0036] (1) Preparation of polymer

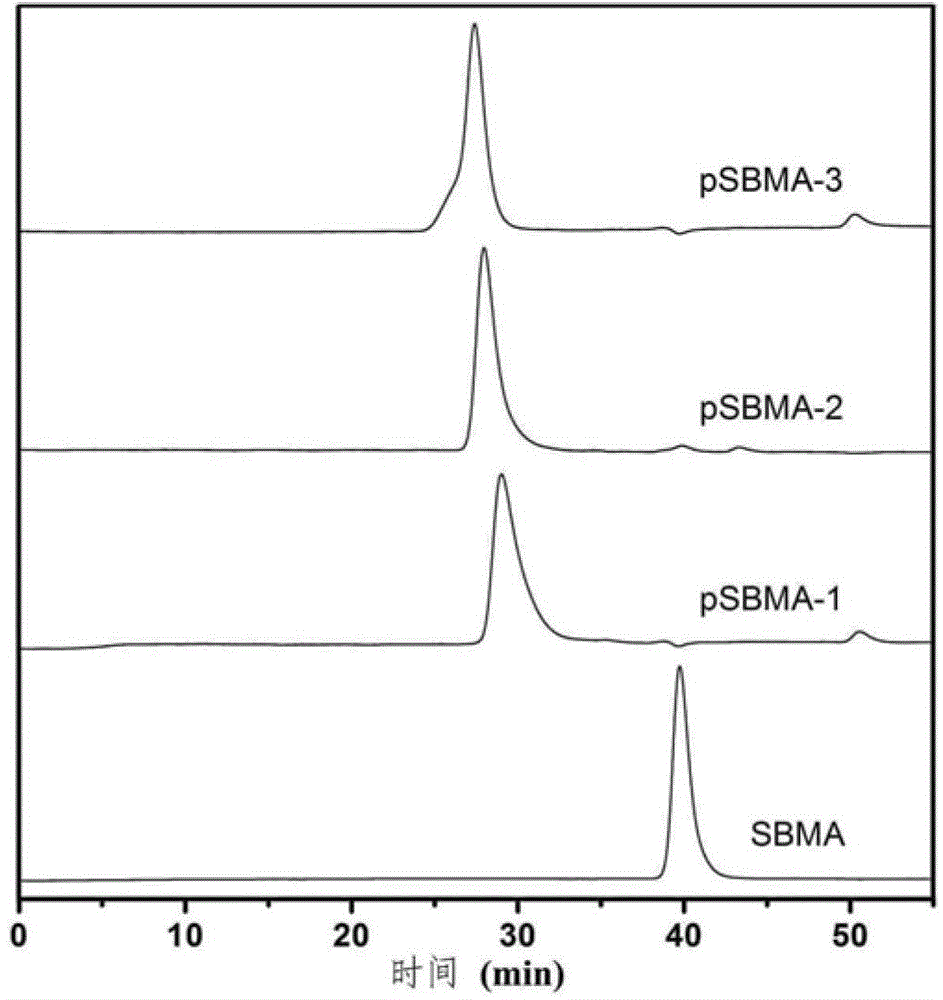

[0037] 1) Using the reversible addition‐fragmentation chain transfer (RAFT) polymerization method, take a 10 mL eggplant-shaped reaction bottle with a branch tube, add 4‐cyanovaleric acid dithiobenzoic acid, 4,4' ‐Azobis(4‐cyanovaleric acid), monomeric thiobetaine methyl acrylate (SBMA). Then add a 10:1 (volume ratio) mixture of methanol and deionized water, put it into a stirrer, dissolve the solid quickly, seal the reaction bottle, and pass nitrogen gas for 30 minutes under ice bath conditions. The oxygen-free reaction system was placed in an oil bath at 60°C to react to obtain a polymer (named pSBMA). During the whole operation, pay attention to protect from light with tin foil.

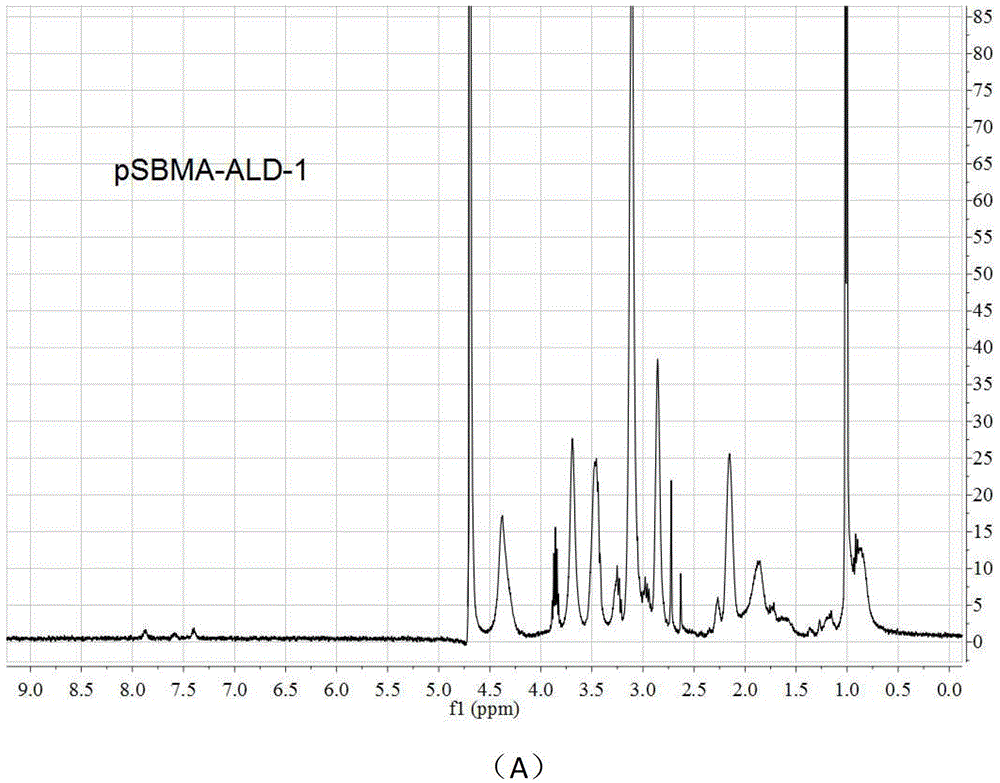

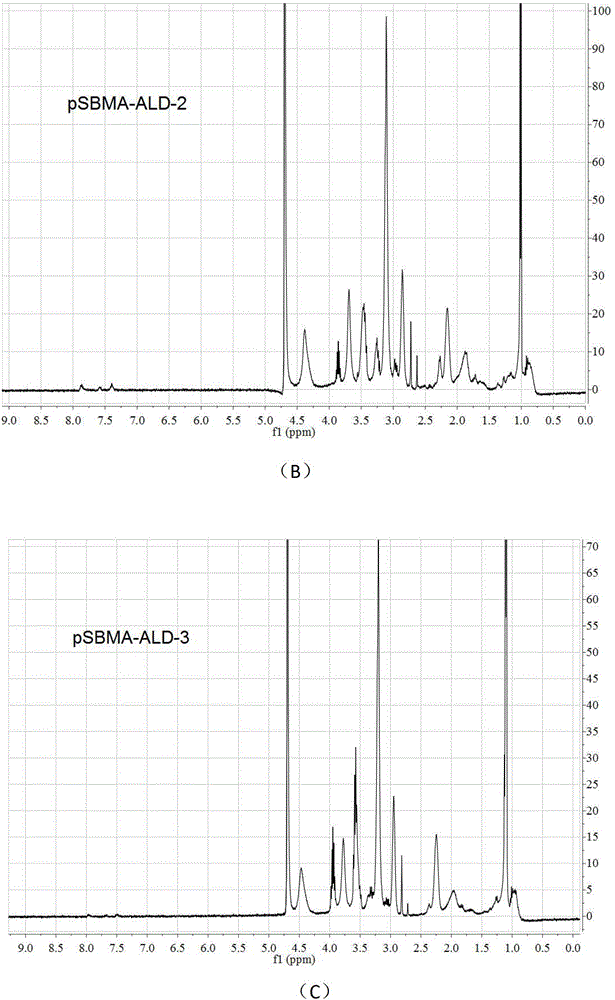

[0038] 2) Condensation acylation reaction of carboxylic acid and amine is adopted, and a 1 mL centrifuge tube is used as a reaction vessel. First, pSBMA was dissolved in 2‐(N‐morpholine)e...

Embodiment 2

[0052] Example 2: Functionalized self-assembly of stainless steel surfaces

[0053] (1) Preparation of polymer

[0054] 1) Using the reversible addition‐fragmentation chain transfer (RAFT) polymerization method, take a 10 mL eggplant-shaped reaction bottle with a branch tube, add 4‐cyanovaleric acid dithiobenzoic acid, 4,4' ‐Azobis(4‐cyanovaleric acid), monomeric thiobetaine methyl acrylate (SBMA). Then add a 10:1 (volume ratio) mixture of methanol and deionized water, put it into a stirrer, dissolve the solid quickly, seal the reaction bottle, and pass nitrogen gas for 30 minutes under ice bath conditions. The oxygen-free reaction system was placed in an oil bath at 60°C to react to obtain a polymer (named pSBMA). During the whole operation, pay attention to protect from light with tin foil.

[0055] 2) Condensation acylation reaction of carboxylic acid and amine is adopted, and a 1 mL centrifuge tube is used as a reaction vessel. First, pSBMA was dissolved in 2‐(N‐morpho...

Embodiment 3

[0070] Example 3: Fe 3 o 4 Surface Modification of Magnetic Nanoparticles

[0071] (1) Preparation of polymer

[0072] 1) Using the reversible addition‐fragmentation chain transfer (RAFT) polymerization method, take a 10 mL eggplant-shaped reaction bottle with a branch tube, add 4‐cyanovaleric acid dithiobenzoic acid, 4,4' ‐Azobis(4‐cyanovaleric acid), monomeric thiobetaine methyl acrylate (SBMA). Then add a 10:1 (volume ratio) mixture of methanol and deionized water, put it into a stirrer, dissolve the solid quickly, seal the reaction bottle, and pass nitrogen gas for 30 minutes under ice bath conditions. The oxygen-free reaction system was placed in an oil bath at 60°C to react to obtain a polymer (named pSBMA). During the whole operation, pay attention to protect from light with tin foil.

[0073] 2) Condensation acylation reaction of carboxylic acid and amine is adopted, and a 1 mL centrifuge tube is used as a reaction vessel. First, pSBMA was dissolved in 2‐(N‐morph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com