Preparation method of bipolar membrane

A bipolar membrane, membrane liquid technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the mechanical and electrochemical properties that are difficult to meet practical requirements, poor ion permeability, and ion transmission efficiency. Small and other problems, to achieve the effect of small membrane impedance, high working current density and low working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] 1. Preparation of bipolar membrane:

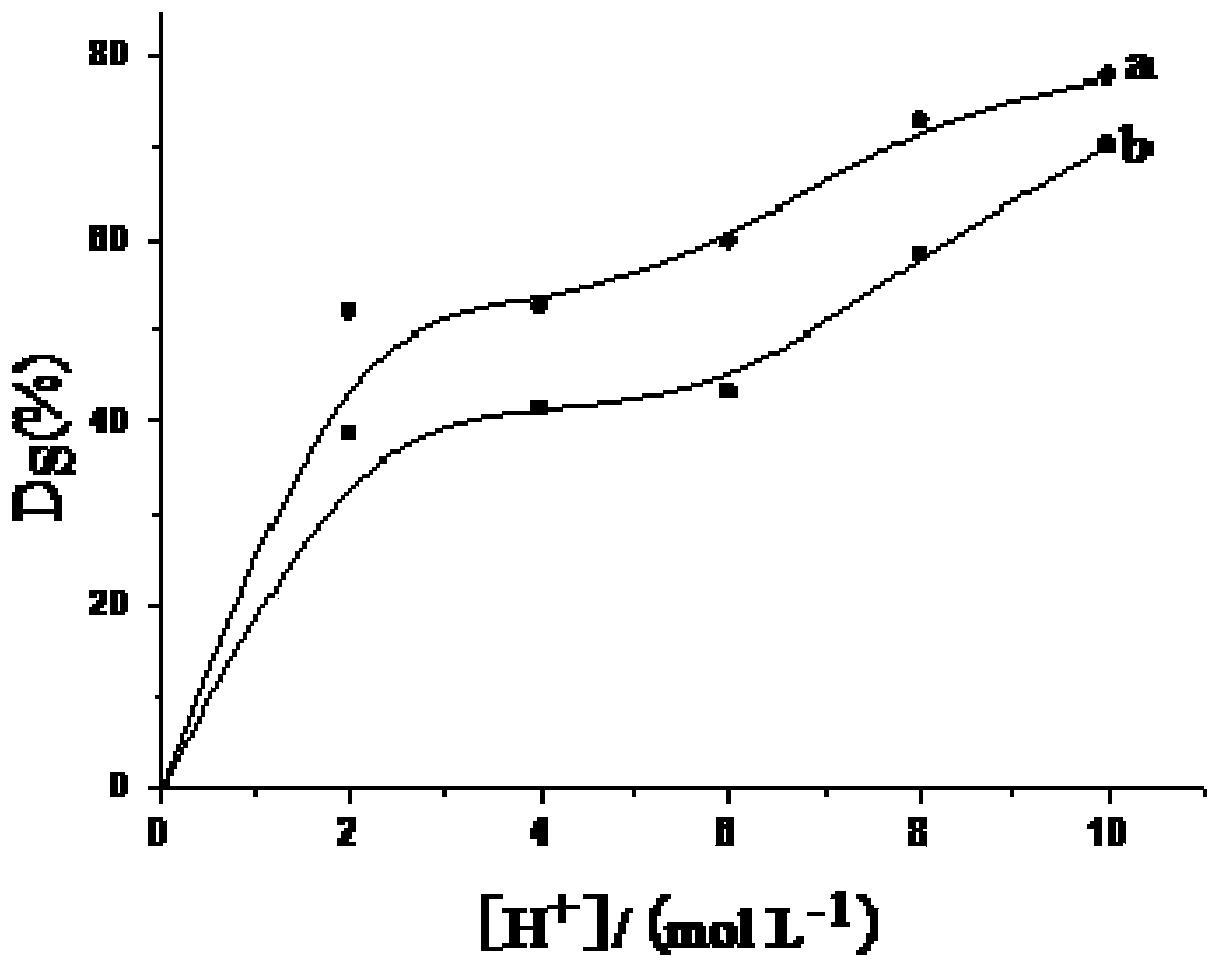

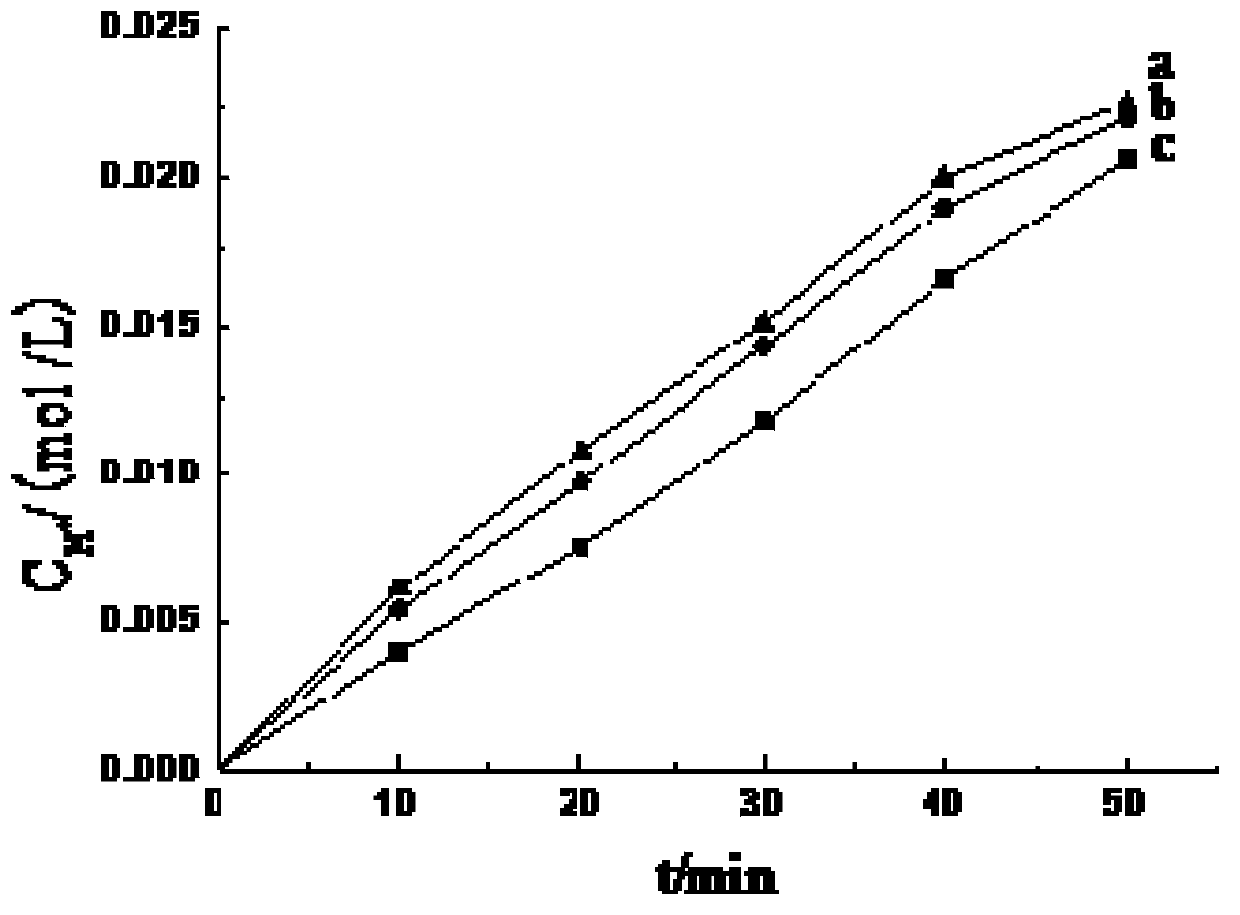

[0025] (1) Preparation of PAMPSLi membrane solution: PVA-SA sol was prepared by blending 3% sodium alginate solution with 6% polyvinyl alcohol, and 2% and 4% PAMPSLi was added in the PVA-SA sol, stirred evenly, and degassed under reduced pressure to obtain a viscous PAMPSLi film liquid, wherein the ratio of the amount of the sodium alginate, polyvinyl alcohol and PAMPSLi added was 1:1 :1;

[0026] (2) Preparation of PAMPSLi-SA membrane: cast the PAMPSLi membrane solution on a flat petri dish, air-dry at room temperature to form a film, and then place the air-dried film in an 8.0% ferric chloride solution Soak in medium for cross-linking for 30min, rinse with distilled water, and air-dry to obtain 2%PAMPSLi-SA film and 4%PAMPSLi-SA film;

[0027] (3) Preparation of PAMPSLi-SA / mCS bipolar membrane: Chitosan was dissolved in 2% acetic acid aqueous solution to prepare chitosan acetic acid solution with 3% mass fraction, and then added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com