Solid-state ion conductor and lithium-enrich manganese-based material composite electrode and lithium ion battery

A lithium-ion battery and ion conductor technology, applied in the direction of electrode carrier/collector, battery electrode, secondary battery, etc., can solve the problem of high cost, complicated preparation process, difficulty in controlling the integrity and thickness uniformity of the coating layer on the surface of the material and other issues, to achieve the effect of low manufacturing cost, good reproducibility, and excellent lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take 90 parts of 0.5Li 2 MnO 3 0.5LiNi 0.5 mn 0.5 o 2 type Li-rich manganese-based materials with 2 parts of solid-state ionic conductor Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 , grind and mix in a mortar for 0.5h, then add the obtained mixed powder, 2 parts of conductive carbon black, 2 parts of conductive graphite, and 4 parts of PVDF into NMP, and stir well to obtain a lithium-rich manganese-based electrode slurry After that, the slurry is coated on an aluminum foil, dried, and rolled to obtain a composite electrode sheet of a solid-state ion conductor and a lithium-rich manganese matrix. The lithium-rich manganese-based electrode pole piece, separator and lithium sheet were assembled in an argon-filled glove box, and the electrolyte was injected to prepare a lithium-rich manganese-based lithium-ion button battery.

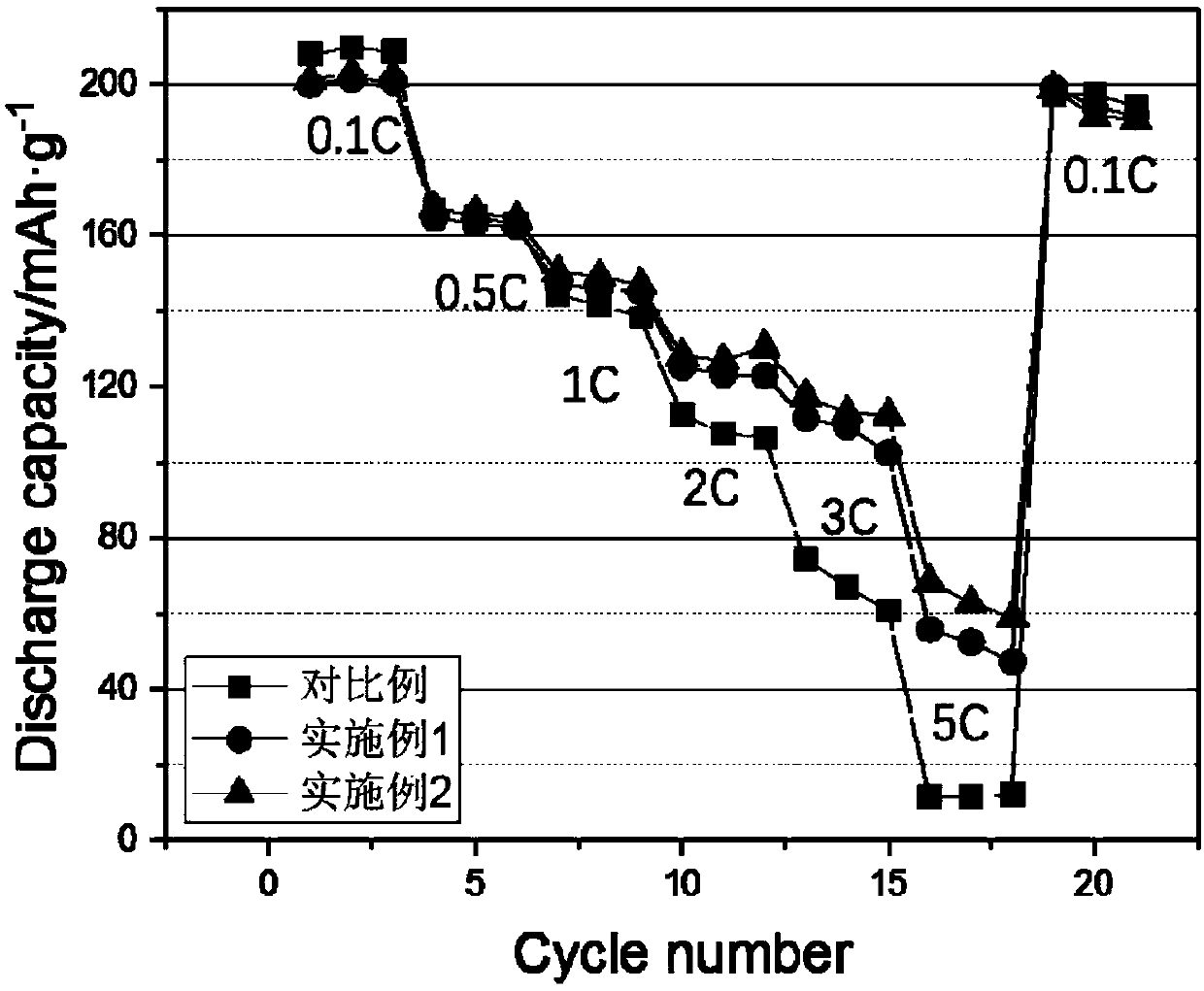

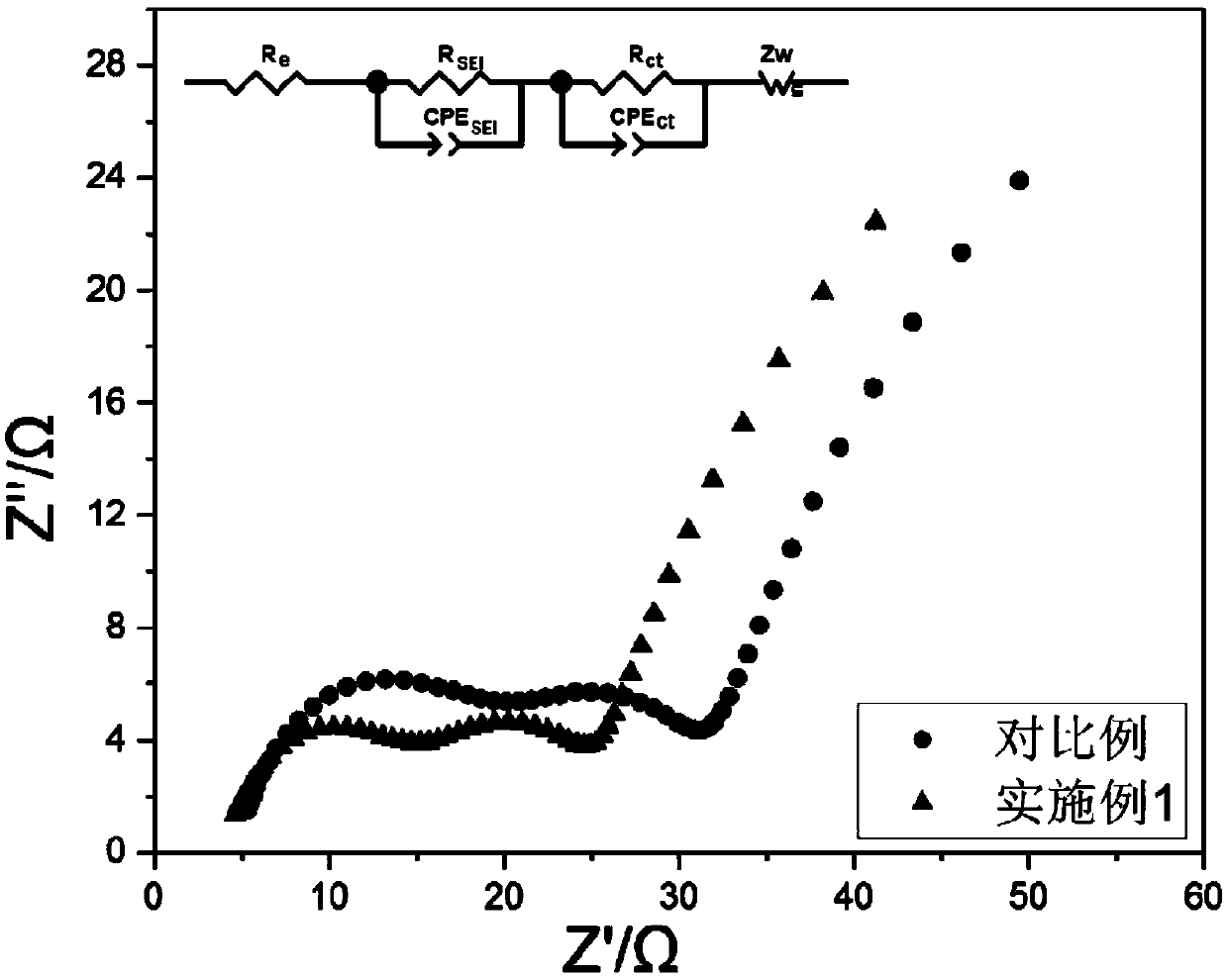

[0036] The high-rate discharge performance of the battery of the comparative example and the battery of Example 1 was tested. Wherein, the discharge spec...

Embodiment 2

[0039] Take 90 parts of 0.5Li 2 MnO 3 0.5LiNi 0.5 mn 0.5 o 2 type Li-rich manganese-based materials with 1 part of solid-state ionic conductor Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 , grind and mix in a mortar for 0.5h, then add the obtained mixed powder, 2 parts of conductive carbon black, 3 parts of conductive graphite, and 4 parts of PVDF into NMP, and stir well to obtain a lithium-rich manganese-based electrode slurry After that, the slurry is coated on an aluminum foil, dried, and rolled to obtain an electrode sheet composed of a solid-state ion conductor and a lithium-rich manganese matrix. The lithium-rich manganese-based electrode pole piece, separator and lithium sheet were assembled in an argon-filled glove box, and the electrolyte was injected to prepare a lithium-rich manganese-based lithium-ion button battery.

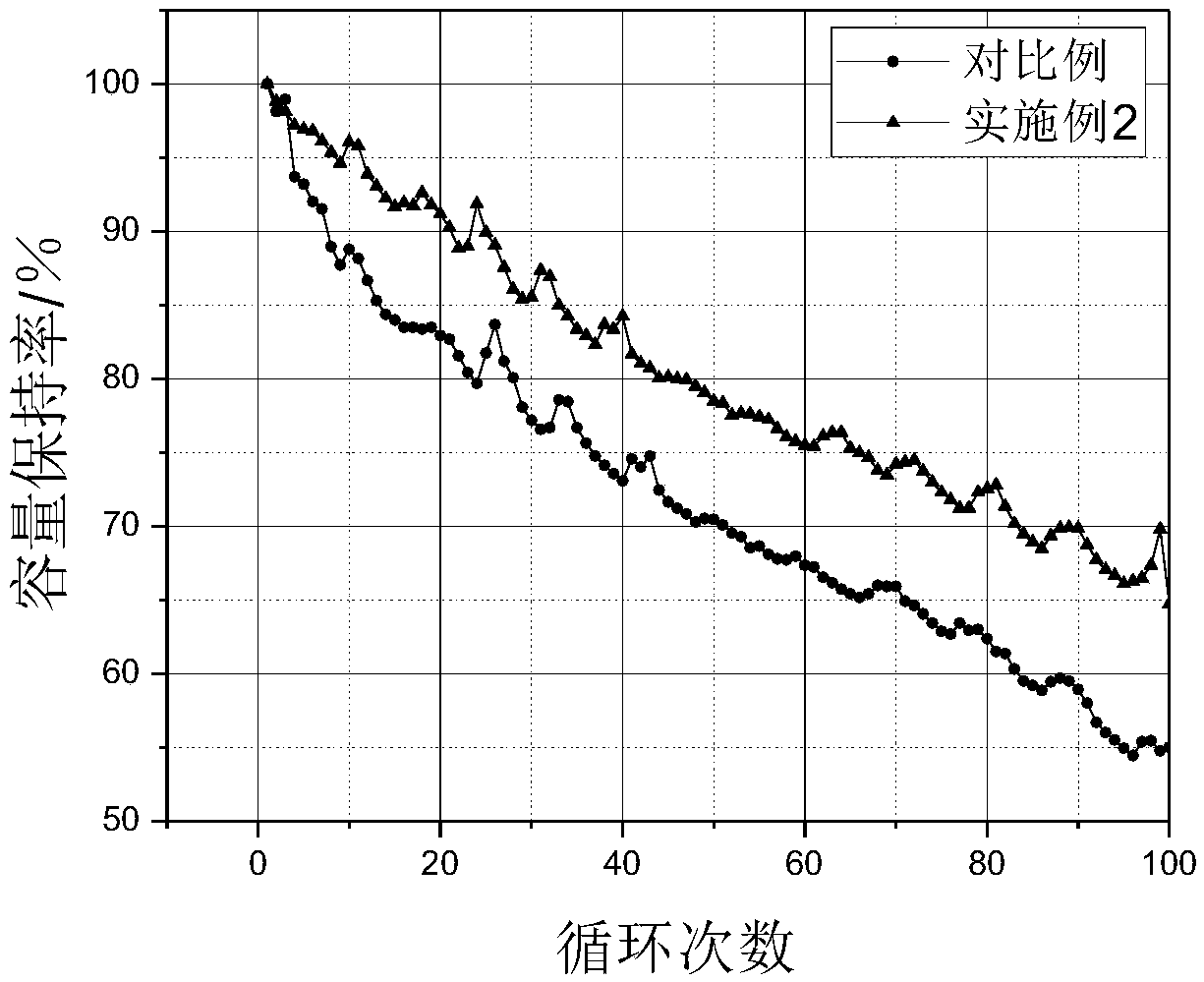

[0040] The discharge specific capacity of the battery reaches 201.2mAh / g at the 0.1C rate, 167.2mAh / g at the 0.5C rate, 150.2mAh / g at the 1C rate, and 15...

Embodiment 3

[0043] Take 92 parts of 0.6Li 2 MnO 3 0.4LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 type Li-rich manganese-based materials with 3 parts of solid-state ionic conductor Li 1.4 Al 0.4 Ti 1.6 (PO 4 ) 3 , ball milling and mixing for 1 h, then adding the resulting mixed powder, 1.8 parts of conductive carbon black, 0.2 parts of carbon nanotubes, and 3 parts of PVDF into NMP, and fully stirring to obtain a lithium-rich manganese-based electrode slurry, and then The slurry is coated on the aluminum foil, and after drying, rolling and slicing, the lithium-rich manganese-based electrode sheet is obtained. Mix the artificial graphite negative electrode material, conductive carbon black, conductive graphite, and PVDF uniformly in a ratio of 93:1:1:5, coat it on the copper foil, and obtain the negative electrode sheet after drying, rolling, and slicing. The lithium-rich manganese-based electrode pole piece, separator, and negative electrode pole piece are assembled and sealed into an aluminum-pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com