Polyvinylidene fluoride/polyalkenes sulfonate cation exchange alloy membrane preparation method

A technology of polyolefin sulfonate and cation exchange, which is applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of huge influence on membrane performance, meet the requirements of practical application, reduce membrane resistance, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

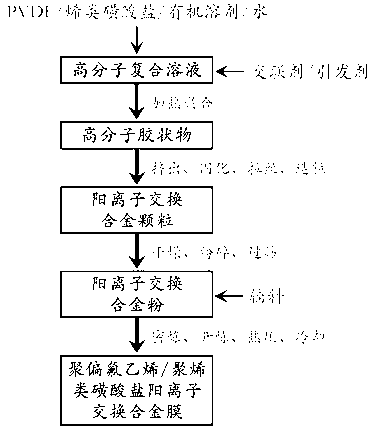

[0014] like figure 1 Shown, the preparation method of polyvinylidene fluoride / polyolefin sulfonate cation exchange alloy membrane of the present invention, the method may further comprise the steps:

[0015] 1. Preparation of polymer composite solution. First, polyvinylidene fluoride, olefin sulfonate, organic solvent and water are stirred at 50-100°C until completely dissolved according to the mass ratio of 1:0.3~1.2:2~10:0~0.5; Then add cross-linking agent and initiator, the mass ratio of cross-linking agent and olefin sulfonate is 0.02~0.2:1, the mass ratio of initiator and olefin sulfonate is 0.05~0.2:1, after fully mixing to get Homogeneous polymer complex solution.

[0016] The alkene sulfonate used is sodium propylene sulfonate or sodium methacrylene sulfonate, which can be one of them or a mixture of the two in any mass ratio. The mass ratio of olefin sulfonate to polyvinylidene fluoride is 0.3~1.2:1. If the ratio is too small, the ion exchange capacity after polyme...

Embodiment 1

[0023] 1. Preparation of polymer composite solution. In a 5-liter glass interlayer reactor, add 500 grams of polyvinylidene fluoride powder (brand FR904, Shanghai Sanaifu Company) and 400 grams of sodium methacrylate (purity: 99.5%, 2.52 moles), and pour into 4 liters of Dimethylacetamide was heated to 85°C and stirred for 1 hour; maintaining rapid stirring, 100 ml of deionized water was added dropwise very slowly, and stirring was continued for 1 hour to form a completely dissolved homogeneous solution. Cool down to 65°C, slowly add 38 g of divinylbenzene (63.2% content, provided by Shangyu Puer Resin Co., Ltd.) dropwise with a 100 ml constant pressure funnel, and continue stirring for 15 minutes; add 45 g of azobisisobutyronitrile, continue After stirring for 1 hour, a homogeneous polymer composite solution was obtained.

[0024] 2. Preparation of cation exchange alloy powder. By means of temperature programming, the composite solution was heated, polymerized at 65°C for 2...

Embodiment 2

[0028] 1. Preparation of polymer composite solution. In a 5-liter glass interlayer reactor, add 500 grams of polyvinylidene fluoride powder (brand FR904, Shanghai Sanaifu Company) and 350 grams of sodium propylene sulfonate (99.5% purity, 2.42 moles), and pour 4.2 liters of dimethylformamide base sulfoxide, heated to about 80°C, and stirred for 1 hour; maintained rapid stirring, very slowly dripped 125 ml of deionized water, and continued to stir for 1 hour to form a completely dissolved homogeneous solution. Cool down to 65°C, slowly add 38 grams of trimethylolpropane diallyl ether (the total content of allyl ether is 98.7%, of which the content of di-ether is 84.5%) dropwise with a 100 ml constant pressure funnel, purchased from Shenzhen Feiyang Chemical Co., Ltd.), continue to stir for 15 minutes; add 40 grams of benzoyl peroxide, continue to stir for 1 hour to obtain a homogeneous polymer composite solution.

[0029] 2. Preparation of cation exchange alloy powder. By mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com