Method for efficiently preparing deoxynivanol

A falkenol and high-efficiency technology, applied in the field of natural product extraction, can solve the problems of long production cycle, low product purity, waste of manpower and material resources, etc., to save usage and sample processing time, reduce production costs, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

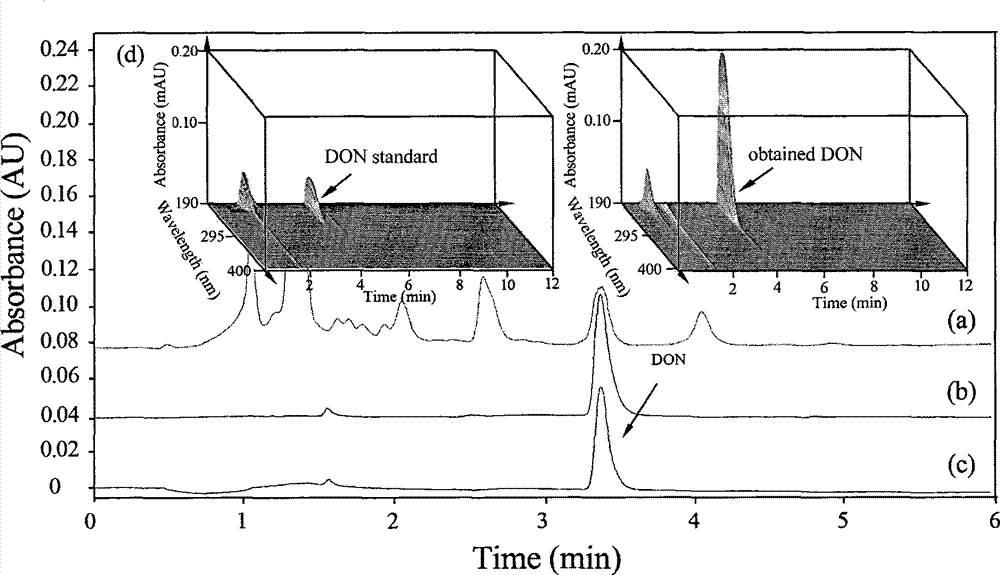

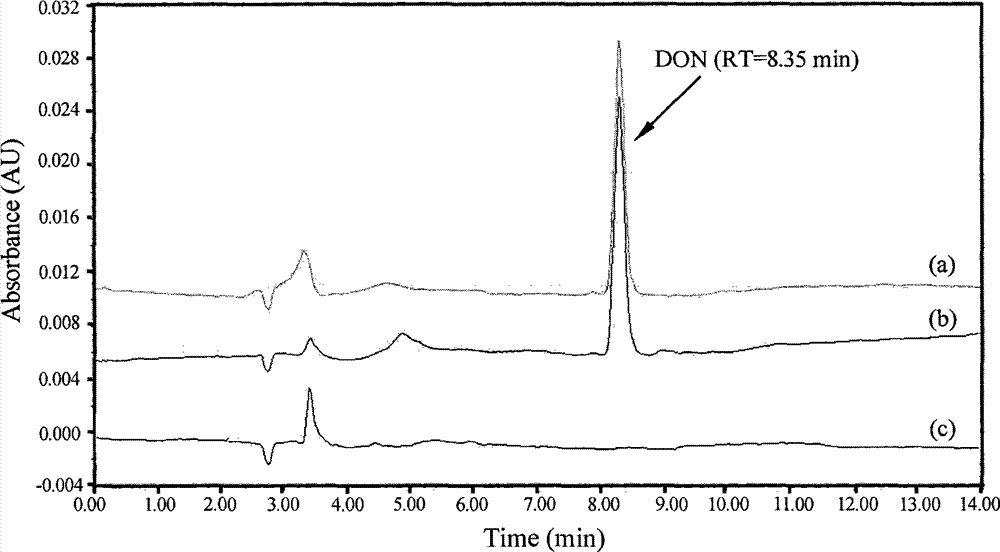

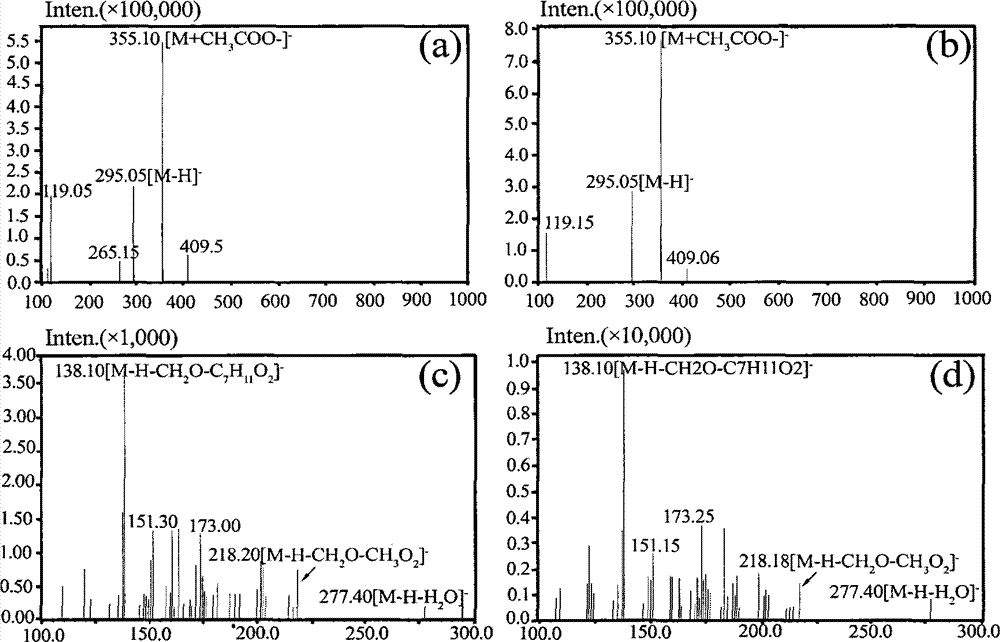

Embodiment 1

[0029] Example 1: Fusarium was cultured on potato medium at 28°C for 3 days in the dark, and then the mycelia were inoculated into 200 ml of carboxymethyl cellulose medium and vibrated at 200 r / min at 25°C for 1 day to obtain Fusarium graminearum Spore liquid, adjust the concentration to 1.0×10 by hemocytometer counting 5pcs / ml and save for later use. Weigh 50g of rice into a 200m1 Erlenmeyer flask, add 20m1 of deionized water, and sterilize at 121°C for 30 minutes; inoculate the bacteria block or spore liquid into the sterilized rice medium, and place it at 28°C for 10 days; The rice medium was dried in a drying oven at 50°C for 24 hours, and then crushed into a uniform powder using a high-speed pulverizer. Weigh 100g of dry powder and place it in a conical flask and add different extraction solvents (acetonitrile, 84% acetonitrile water, 50% acetonitrile water, methanol, 70% methanol water, 50% methanol water, ethyl acetate, water) to extract, the extract Place at 4°C for ...

Embodiment 2

[0030] Embodiment 2: The preparation of Fusarium graminearum spore liquid is the same as that in Embodiment 1. Weigh 50g of corn into a 200ml Erlenmeyer flask, add 20ml of deionized water, and sterilize at 121°C for 30min; the rest of the steps are the same as in Example 1.

Embodiment 3

[0031] Example 3: The preparation of Fusarium graminearum spore liquid was the same as in Example 1. Weighed 50 g of wheat into a 200 ml Erlenmeyer flask, added 20 ml of deionized water, and sterilized at 121° C. for 30 minutes; the rest of the steps were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com