Technique for fast filling constructed wetland in shore area

A technology of artificial wetland and process method, applied in civil engineering, rapid filling of artificial wetland in the lakeside area, can solve the problems of high cost, low construction efficiency, difficult consolidation and rapid formation, etc., to improve productivity and reduce engineering. Cost, reduce the effect of rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

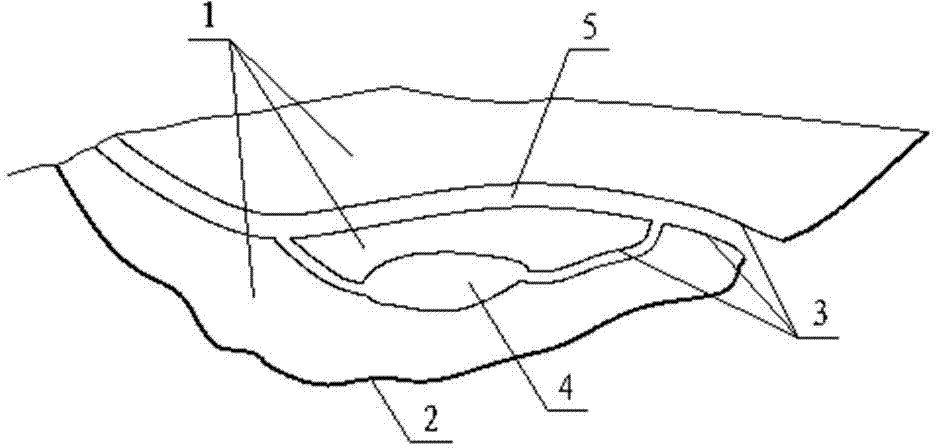

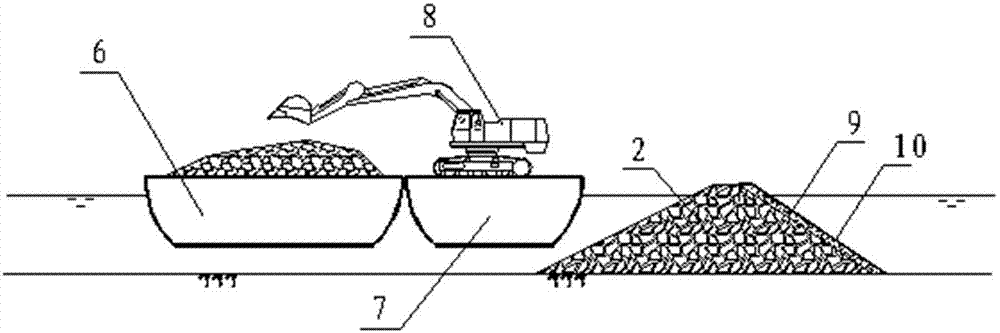

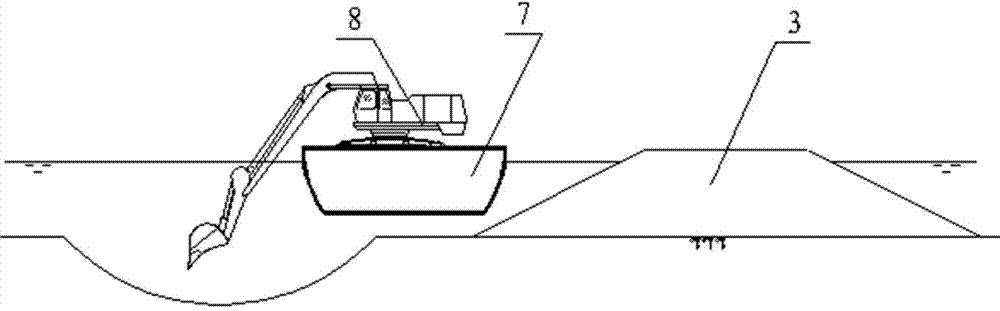

[0036] Such as figure 1 As shown, the shoreline of a city’s lakeside artificial wetland test section project is about 1800m long, with an average width of about 500m, the front and periphery of the wetland in the lake area are about 2450m long, and the wetland area is about 802,300m 2 , 941,000 m of filled earthwork 3 , there are sub-lakes 4, waterways 5 and other landscape water bodies. The wetland filling period is required to be 4 months, and plant measures can be carried out on it immediately after the filling is completed. Although conventional cutter suction dredger dredging construction can meet the construction period requirements, the wetland bearing capacity after filling cannot meet the requirements, and water body landscapes such as sub-lakes and waterways are difficult to organize and form. The construction scheme of grab dredger with mud barge has low construction efficiency, it is difficult to meet the construction period requirements, and the construction cos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com