Dynamic gas lock

A dynamic gas lock and cylinder body technology, which is applied in the direction of microlithography exposure equipment, instruments, photoplate making process of pattern surface, etc., to achieve the effect of inhibiting the diffusion of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

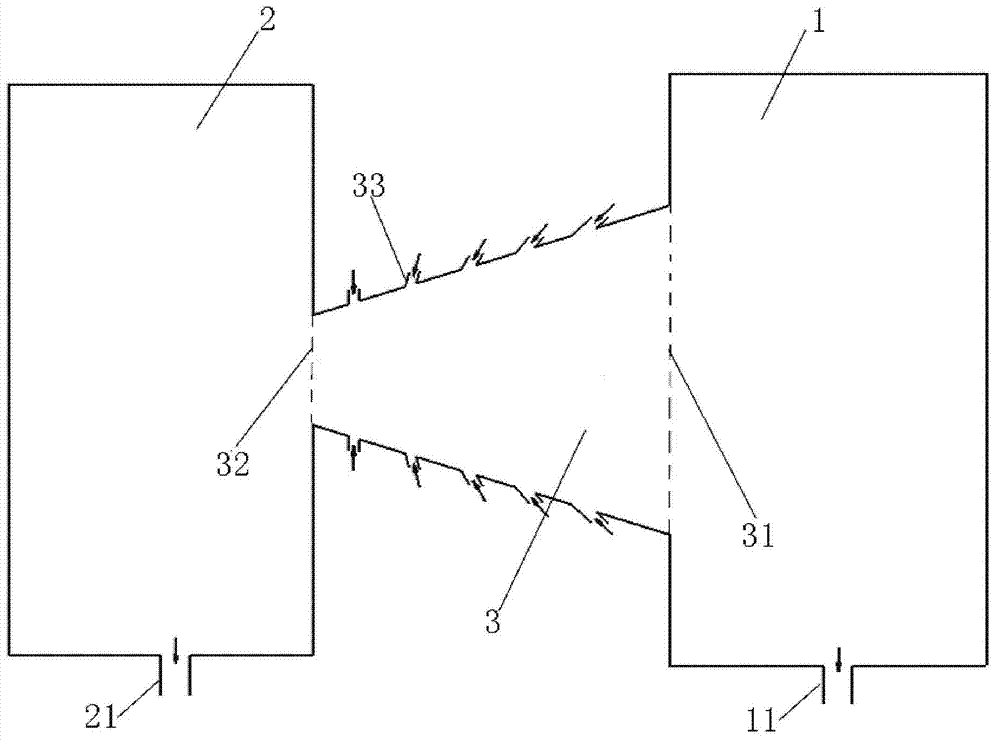

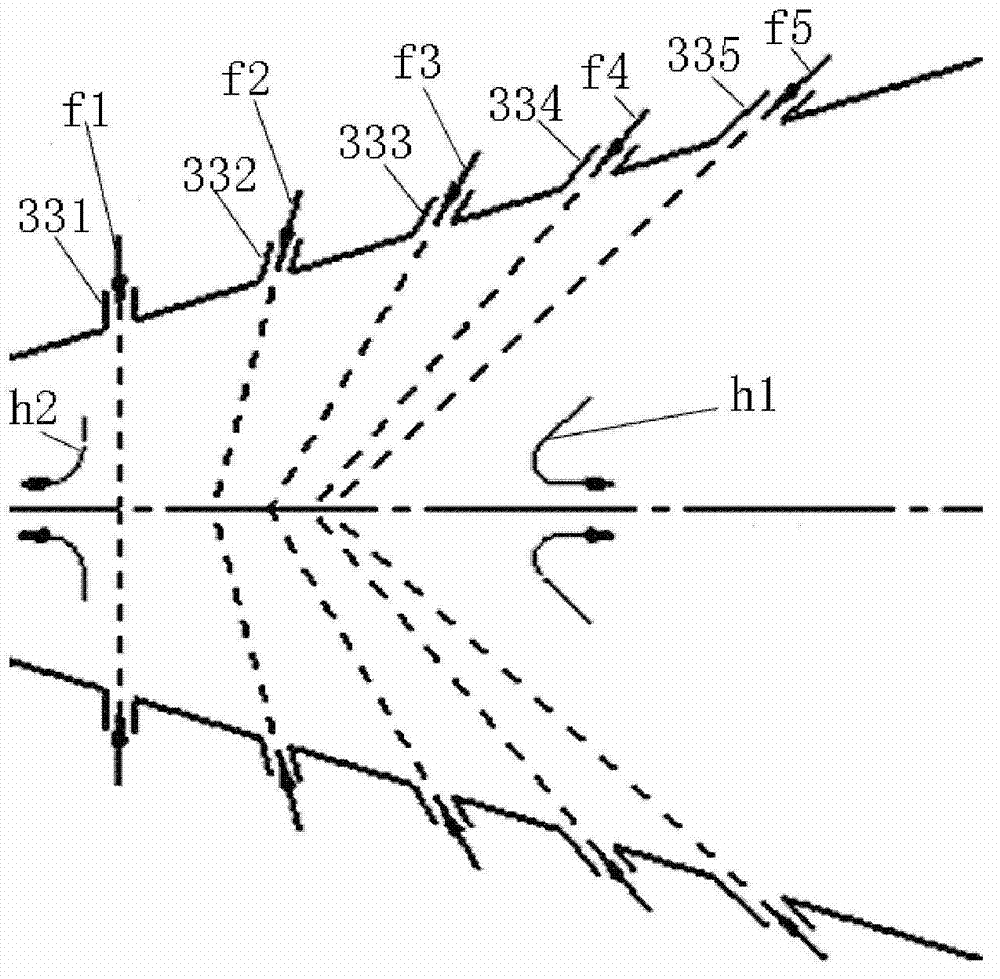

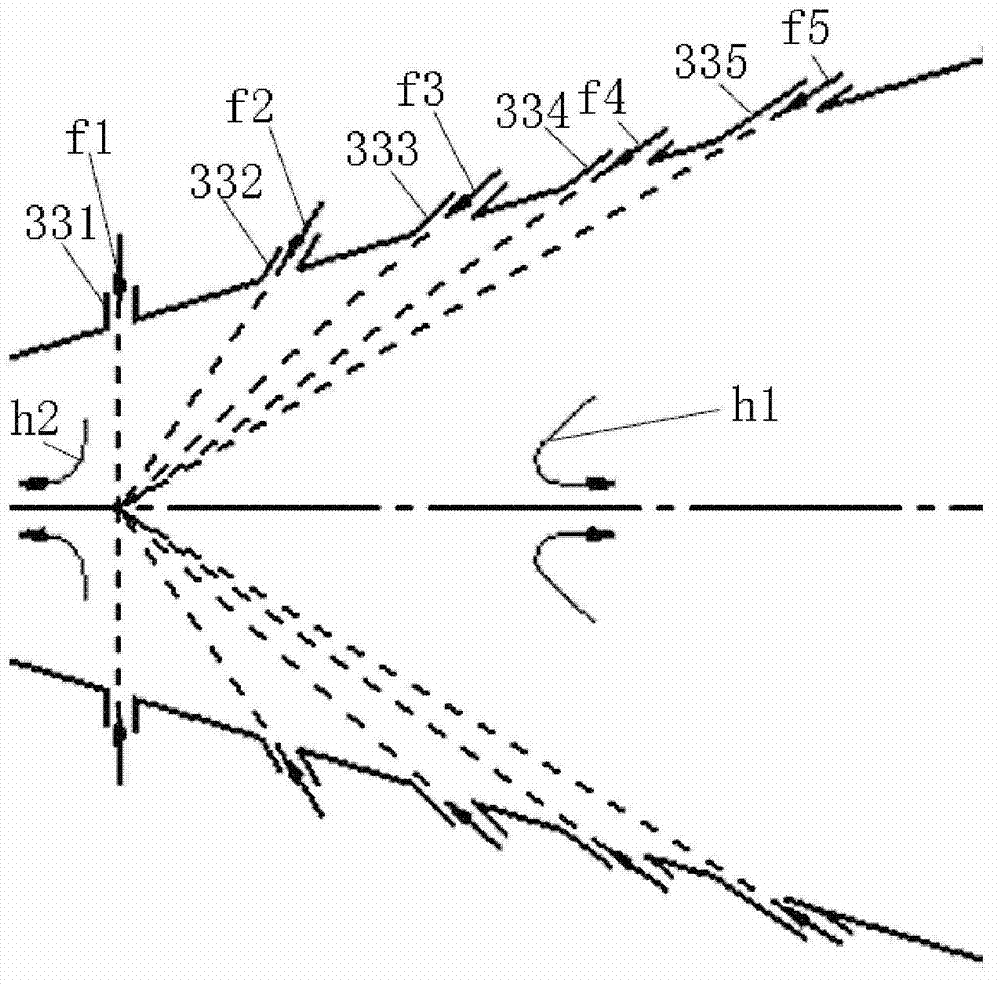

[0026] The dynamic gas lock proposed by the present invention presents a cylindrical shape, including a cylinder body with two ends open, the cylinder body has a wide mouth end and a narrow mouth end, the wide mouth end is connected with a first chamber, and the narrow mouth end is connected with a first chamber Two chambers.

[0027] The dynamic gas lock of the present invention is used to prevent substances in the second chamber from entering the first chamber. For example, the interior of the first chamber is an ultra-clean vacuum environment, and the interior of the second chamber is a clean vacuum environment. The present invention is used to prevent impurities and dust in the clean vacuum environment from entering the ultra-clean vacuum environment.

[0028] A plurality of nozzles are opened on the cylinder body of the cylindrical dynamic gas lock, and the plurality of nozzles all penetrate the side wall of the cylinder body, so as to blow a kind of gas to the inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com