Structure and preparation method of surface electric field enhanced PIN photoelectric detector

A photodetector, surface electric field technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of reducing the spectral response of the detection device, reducing the spectral response of the short-wave band, and reducing the efficiency of carrier collection, and improving the spectral response. , Improve the collection efficiency and increase the effect of the back electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

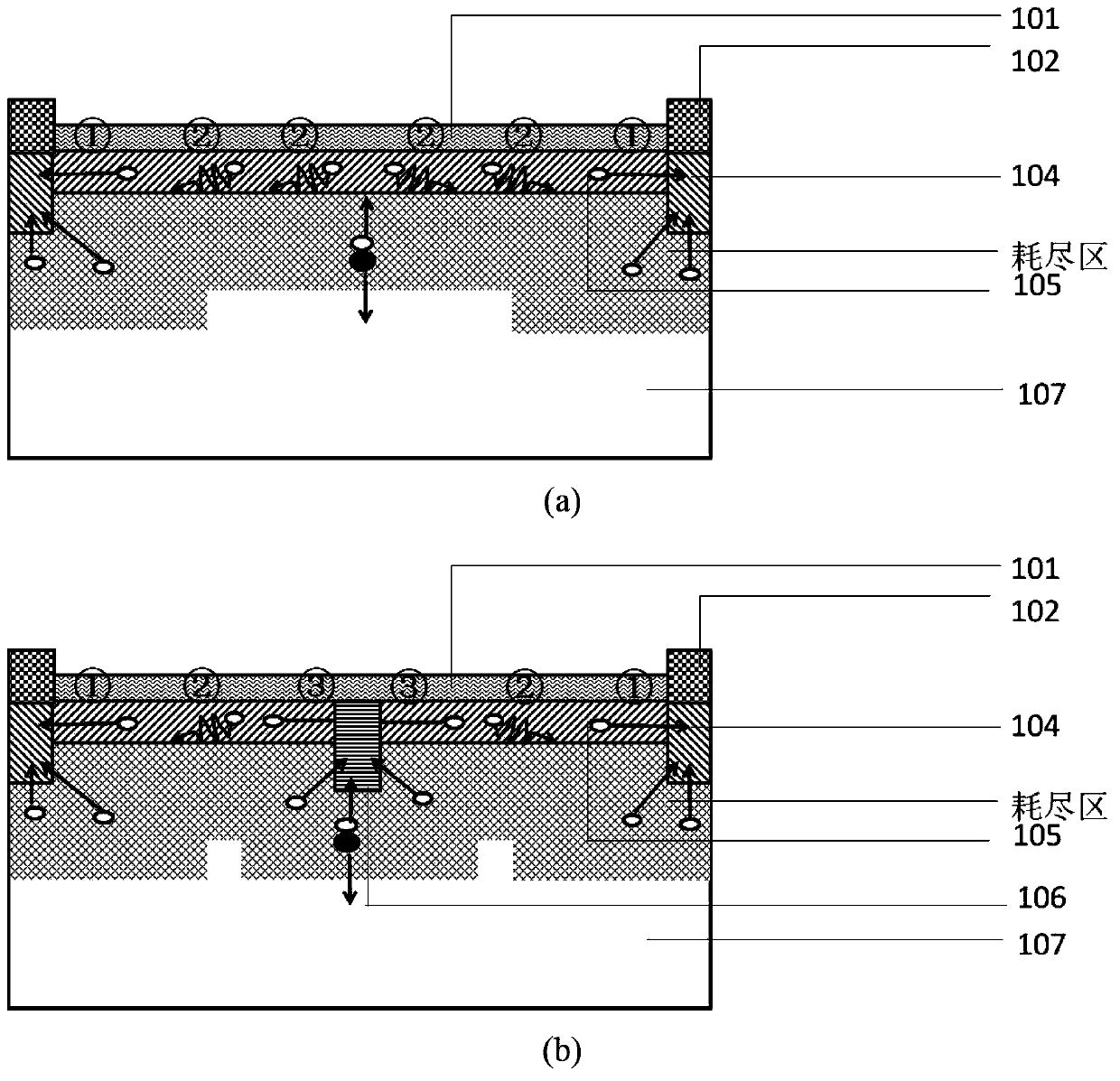

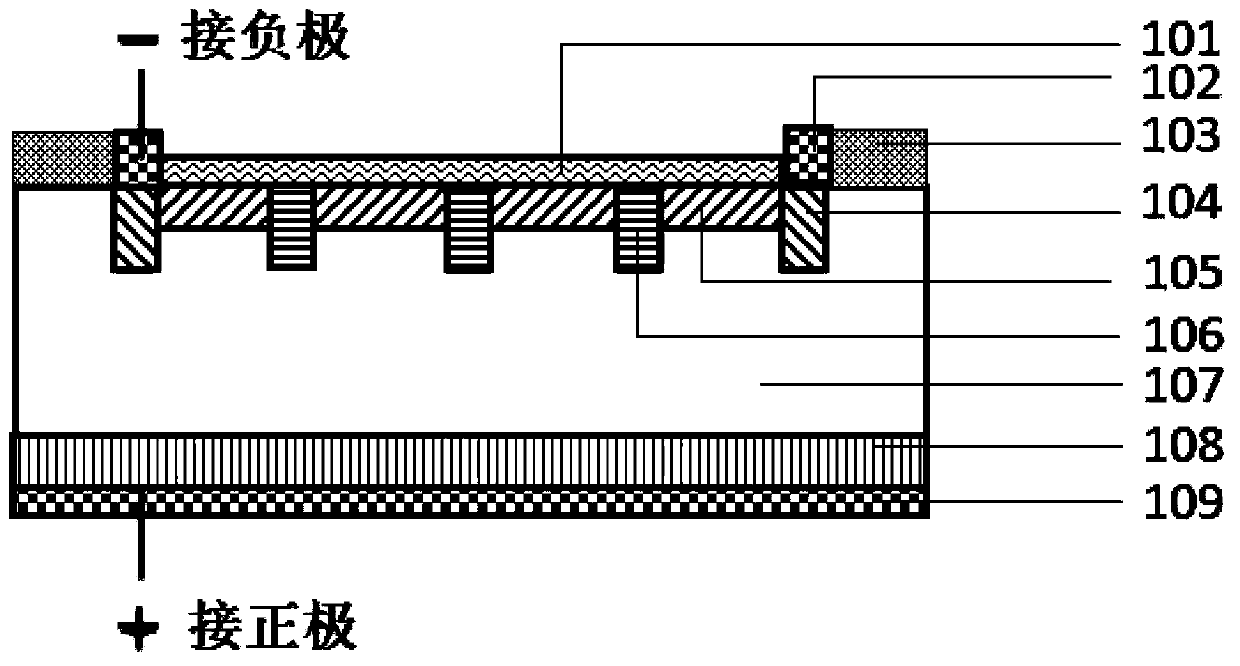

[0031] as attached Figure 5 As shown, the intrinsic layer 107 is made of n-type doped high-resistance silicon material with a doping concentration of 5×10 11 cm -3 , and taking the p-type heavily doped lattice as an example, the preparation process and method are as follows:

[0032] 1. Thermal oxidation or growth of an oxidation protection layer 103 on the surface of the n-type high resistance silicon intrinsic layer 107;

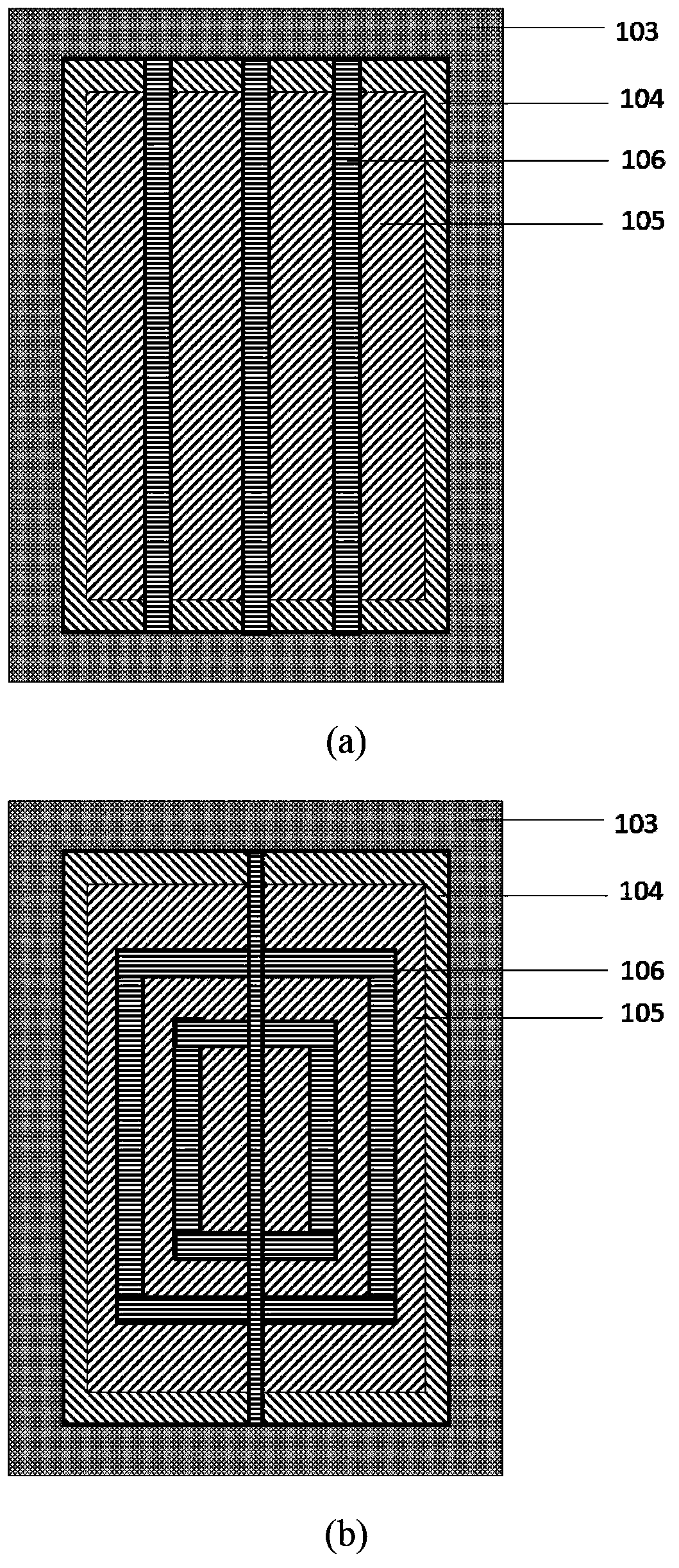

[0033] 2. Photoetching out the pattern of p-type ohmic contact layer 104 and p-type heavily doped lattice 106, etching the front oxidation protection layer 103, injecting boron on the front side of n-type high-resistance silicon intrinsic layer 107 to form p-type ohmic contact Layer 104 and p-type heavily doped lattice 106, the doping concentration is 5×10 19 cm -3 , the depth is 2 μm, the top view of the p-type heavily doped lattice 106 is a square lattice, the length and width are both 20 μm, and the strip width connecting the p-type heavily doped l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com