Adhesive for negative pole material of lithium ion battery and preparation method of electrode containing adhesive

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of first efficiency reduction, cycle and rate performance deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

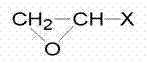

[0022] Example 1, A binder for negative electrode materials of lithium ion batteries, which is a polyacrylic acid polymer, which is formed by condensation of polyacrylic acid and polyether polymers, wherein polyacrylic acid accounts for the polyacrylic acid polymer The percentage by weight of the total weight of the product is 10%, and the molecular weight of the polyether polymer is 100. Polyether polymers include: 1 mol% of repeating units derived from monomers represented by structural formula (I),

[0023] (I)

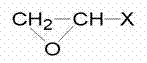

[0024] and 99 mol% of repeating units derived from monomers represented by structural formula (II);

[0025] (II)

[0026] Wherein, X is a methyl group.

Embodiment 2

[0027] Example 2, A binder for negative electrode materials of lithium ion batteries, which is a polyacrylic acid polymer, which is formed by condensation of polyacrylic acid and polyether polymers, wherein polyacrylic acid accounts for the polyacrylic acid polymer The percentage by weight of the total weight of the product is 15%, and the molecular weight of the polyether polymer is 200. Polyether polymers include: 10mol% of repeating units derived from monomers represented by structural formula (I),

[0028] (I)

[0029] and 90 mol% of repeating units derived from monomers represented by structural formula (II);

[0030] (Ⅱ)

[0031] Wherein, X is an ethyl group.

Embodiment 3

[0032] Example 3, A binder for negative electrode materials of lithium ion batteries, which is a polyacrylic acid polymer, which is formed by condensation of polyacrylic acid and polyether polymers, wherein polyacrylic acid accounts for the polyacrylic acid polymer The percentage by weight of the total weight of the product is 20%, and the molecular weight of the polyether polymer is 400. Polyether polymers include: 25mol% of repeating units derived from monomers represented by structural formula (I),

[0033] (I)

[0034] and 75 mol% of repeating units derived from monomers represented by structural formula (II);

[0035] (Ⅱ)

[0036] Wherein, X is a propyl group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com