Preparation method for synthesizing N-TiO2@WSe2 photocatalyst through sol-gel method and application of N-TiO2@WSe2 photocatalyst

A technology of tungsten diselenide and titanium dioxide, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. The method is simple and the effect of improving the dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Solution A: Add 9ml of n-butyl titanate and 27ml of absolute ethanol into a 250ml three-necked flask, place it in a water bath at 40°C, and stir vigorously for 15 minutes;

[0063] (2) Prepare thiourea solution according to the molar ratio of N and Ti being 1:1 respectively, and dissolve 2g of thiourea in 10ml of ethanol;

[0064] (3) Add the prepared thiourea solution drop by drop into solution A under vigorous stirring, and stir at a constant speed for 10 minutes;

[0065] (4) Load 7mmolTiO per 1g of tungsten diselenide 2 Weigh 2.5g of tungsten diselenide, add it into solution A and stir evenly;

[0066] (5) Solution B: Add 36ml of absolute ethanol and 2ml of deionized water into a 50ml volumetric flask, drop in HCl to make the solution acidic, and mix the solution evenly;

[0067] (6) Add solution B into the above mixed solution at a rate of 80 drops / min, and keep stirring at a constant speed for 20 minutes to obtain a black sol;

[0068] (7) Put the black sol...

Embodiment 2

[0070] Prepare solution A and solution B according to the method in embodiment 1, according to every 1g of tungsten diselenide loading 9mmolTiO 2 Weigh 4g of tungsten diselenide, add it into solution A and stir evenly. Other experimental methods are the same as in Example 1.

Embodiment 3

[0072] Prepare solution A and solution B according to the method in embodiment 1, according to every 1g tungsten diselenide loading 13mmolTiO 2 Weigh 6g of tungsten diselenide, add it into solution A and stir evenly. Other experimental methods are the same as in Example 1.

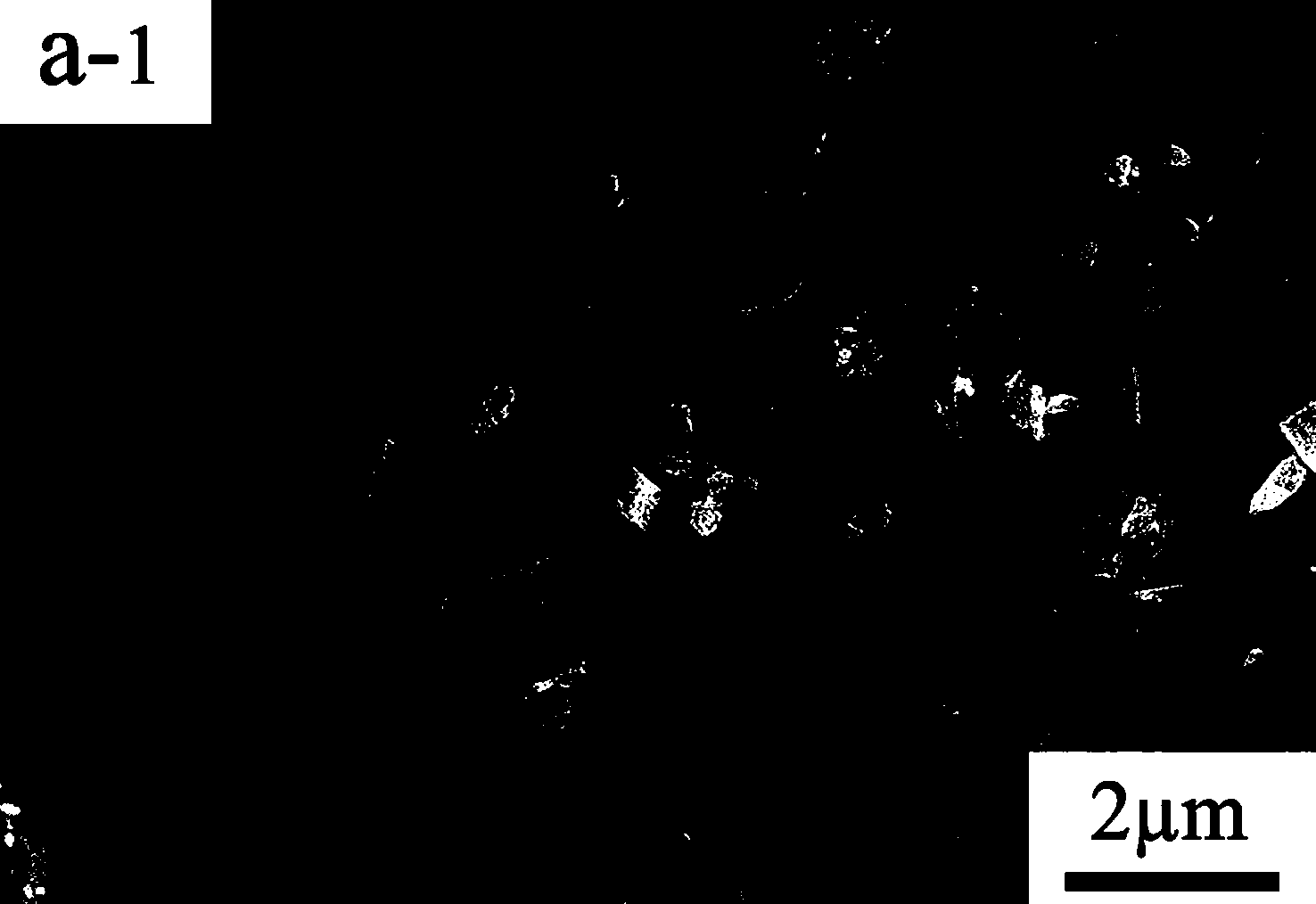

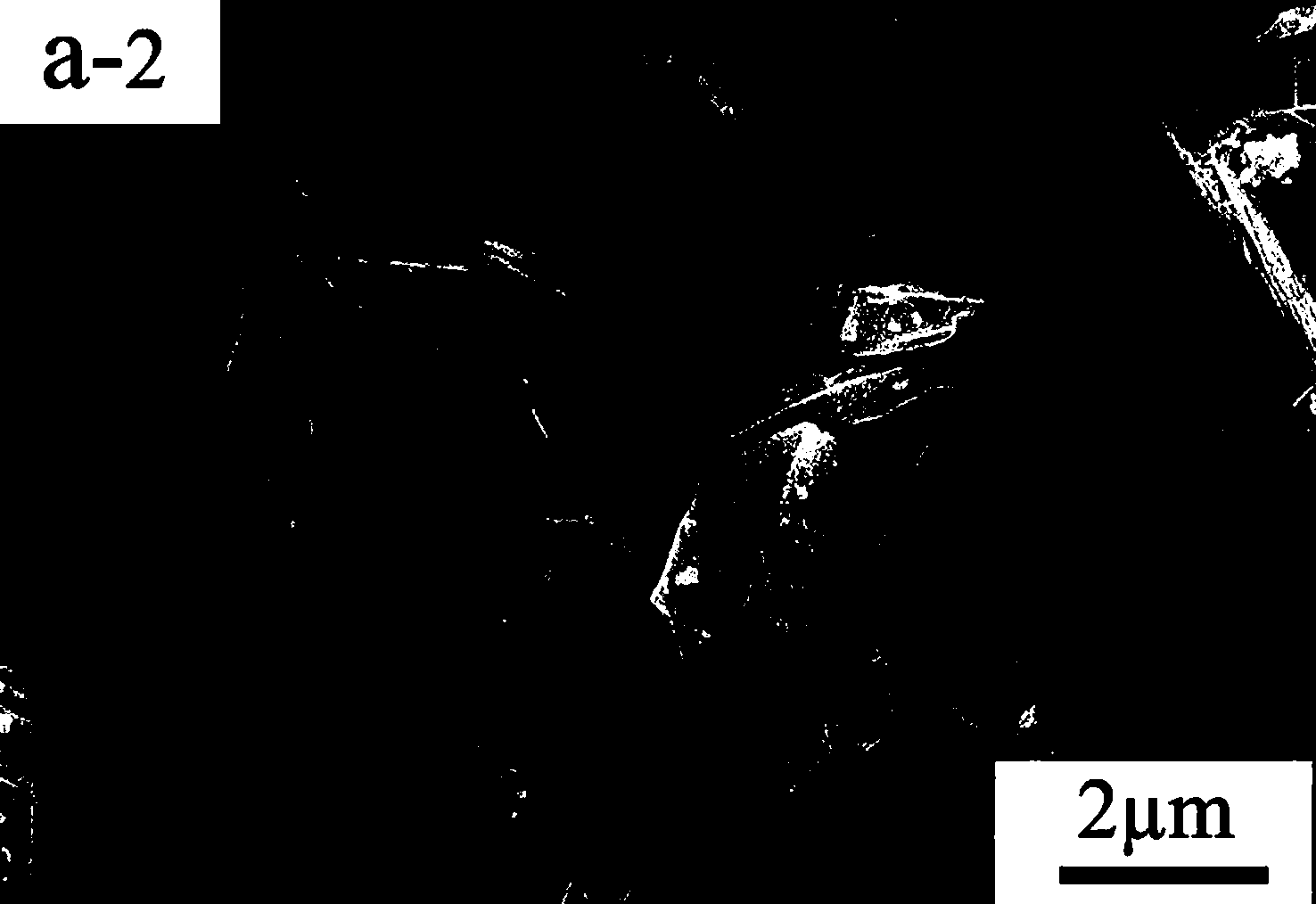

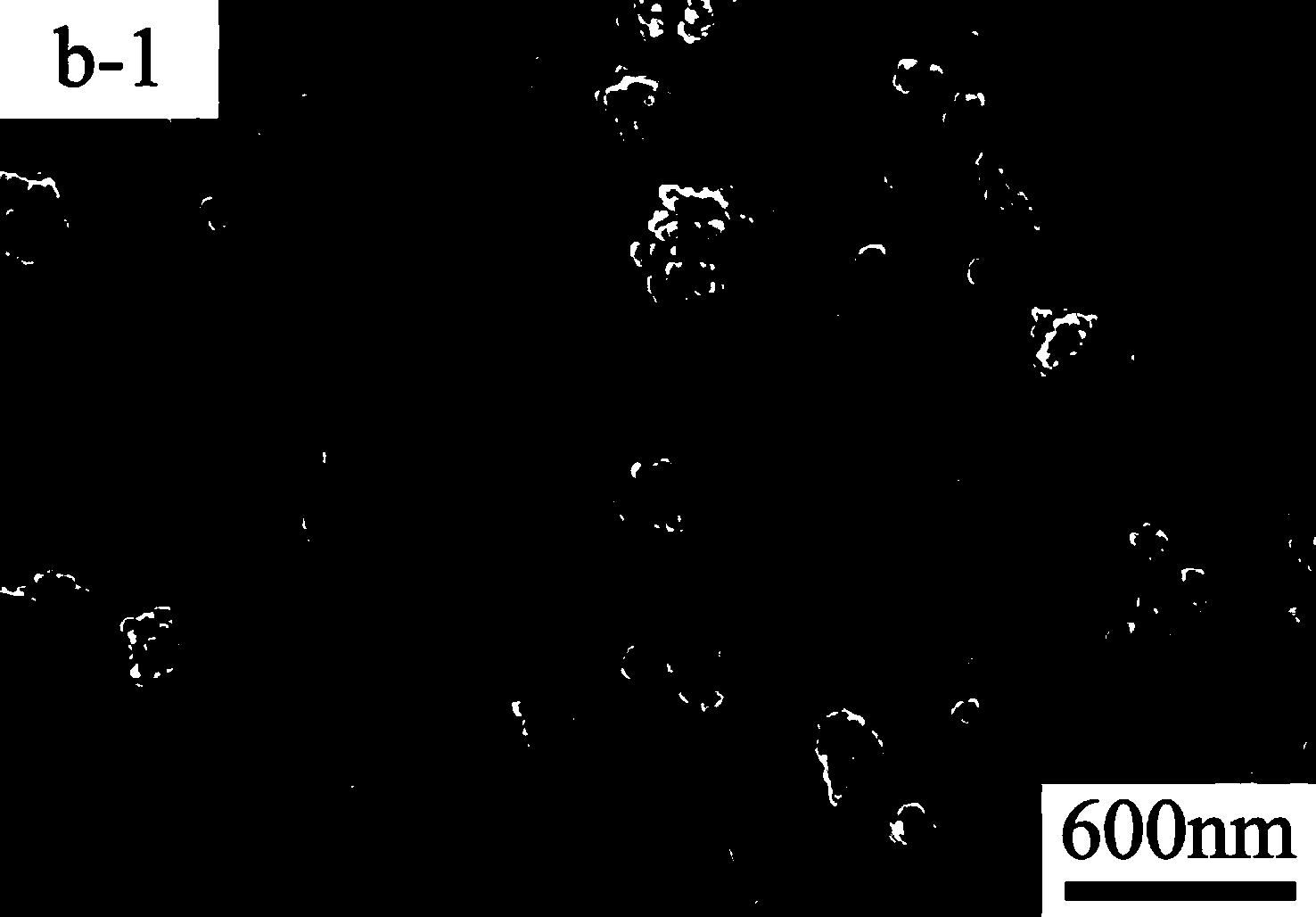

[0073] The comparison of the above three embodiments finds that by comparing the scanning electron microscope images, when adding 9mmolTiO2 per 1g of tungsten diselenide load 2 Weigh 4g of tungsten diselenide and add it into solution A, and the obtained N-TiO 2 WS 2 The photocatalyst has the most uniform morphology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com