Ellipsoidal nitrogen-doped mesoporous carbon, and preparation method and applications thereof

A nitrogen-doped mesoporous carbon, ellipsoid technology, applied in the preparation/purification of carbon, the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., to achieve the effects of easy replication, easy control, and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

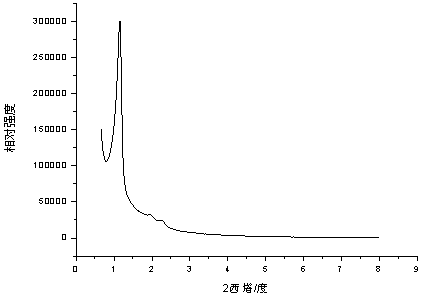

Image

Examples

Embodiment 1

[0049] A method for preparing an ellipsoidal nitrogen-doped mesoporous carbon material, specifically comprising the steps of:

[0050] (1) Dissolve 0.08g of nitrogen-containing precursor in 20ml of ethanol, add 1.0g of ellipsoidal mesoporous silica, then add 1.51g of organic high molecular polymer, and stir to make the organic high molecular polymer and nitrogen-containing precursor The body is fully immersed in the pores of ellipsoidal mesoporous silica, and after the ethanol solvent is volatilized, it is dried at 30°C for 24 hours to obtain nitrogen-doped ellipsoidal mesoporous carbon;

[0051] The amount of the above-mentioned ellipsoidal mesoporous silica, organic polymer, nitrogen-containing precursor and ethanol, according to ellipsoidal mesoporous silica: organic polymer: nitrogen-containing precursor: ethanol is 1g: 1.51g: 0.08g: 20ml ratio calculation;

[0052] The ellipsoidal mesoporous silica has a ratio of major axis to minor axis of 1.732 and a pore volume of 1.0...

Embodiment 2

[0065] A method for preparing an ellipsoidal nitrogen-doped mesoporous carbon material, specifically comprising the steps of:

[0066] (1) Weigh 0.27g of nitrogen-containing precursor and dissolve it in hot deionized water, add 1.0g of ellipsoidal mesoporous silica, stir for 1 hour and place it on the top of the oven until the water evaporates completely, then add 1.36g of organic high Stir the molecular polymer and 20ml of ethanol so that the organic polymer and the nitrogen-containing precursor are fully immersed in the pores of the ellipsoidal mesoporous silica. After the ethanol solvent has evaporated, dry it at 55°C for 24 hours to obtain nitrogen Doped ellipsoidal mesoporous carbon;

[0067] The amount of the above-mentioned ellipsoidal mesoporous silica, organic polymer, nitrogen-containing precursor and ethanol, according to ellipsoidal mesoporous silica: organic polymer: nitrogen-containing precursor: ethanol is 1g: 1.36 g: 0.27g: 20ml ratio calculation;

[0068] Th...

Embodiment 3

[0077] A method for preparing an ellipsoidal nitrogen-doped mesoporous carbon material, specifically comprising the steps of:

[0078] (1) Dissolve 0.31g of nitrogen-containing precursor in 20ml of ethanol, add 1.0g of ellipsoidal mesoporous silica, then add 0.61g of organic polymer, and stir to make the organic polymer and nitrogen-containing precursor Immerse fully into the pores of mesoporous silica, and dry at 55°C for 24 hours after the ethanol solvent evaporates to obtain nitrogen-doped ellipsoidal mesoporous carbon;

[0079] The amount of the above-mentioned ellipsoidal mesoporous silica, organic polymer, nitrogen-containing precursor and ethanol, according to ellipsoidal mesoporous silica: organic polymer: nitrogen-containing precursor: ethanol is 1g: 0.61g: 0.31g: 20ml ratio calculation;

[0080] The ellipsoidal mesoporous silica has a ratio of major axis to minor axis of 1.732 and a pore volume of 1.0-1.5 cm 3 / g;

[0081] Described organic polymer is furfuryl alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com