Method for cooling biomass gasification gas and recovering waste heat by using heat exchanger

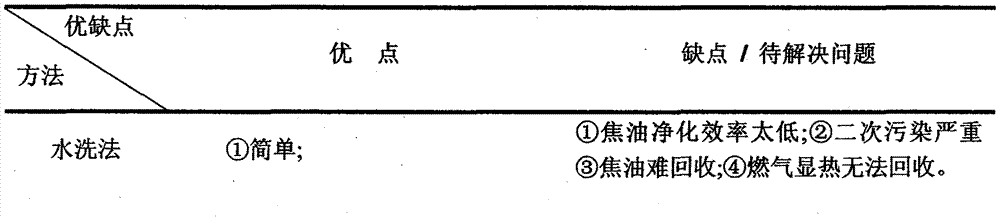

A heat exchanger, biomass technology, applied in the manufacture of combustible gas, chemical industry, climate sustainability, etc., can solve problems such as low tar decomposition efficiency, catalyst problem, secondary pollution, etc., to avoid organic alkali metal/alkaline earth The problem of secondary metal release, the effect of improving usability and added value, and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further described below in conjunction with specific embodiments.

[0039] A method for cooling biomass gasification gas and recovering waste heat using a heat exchanger:

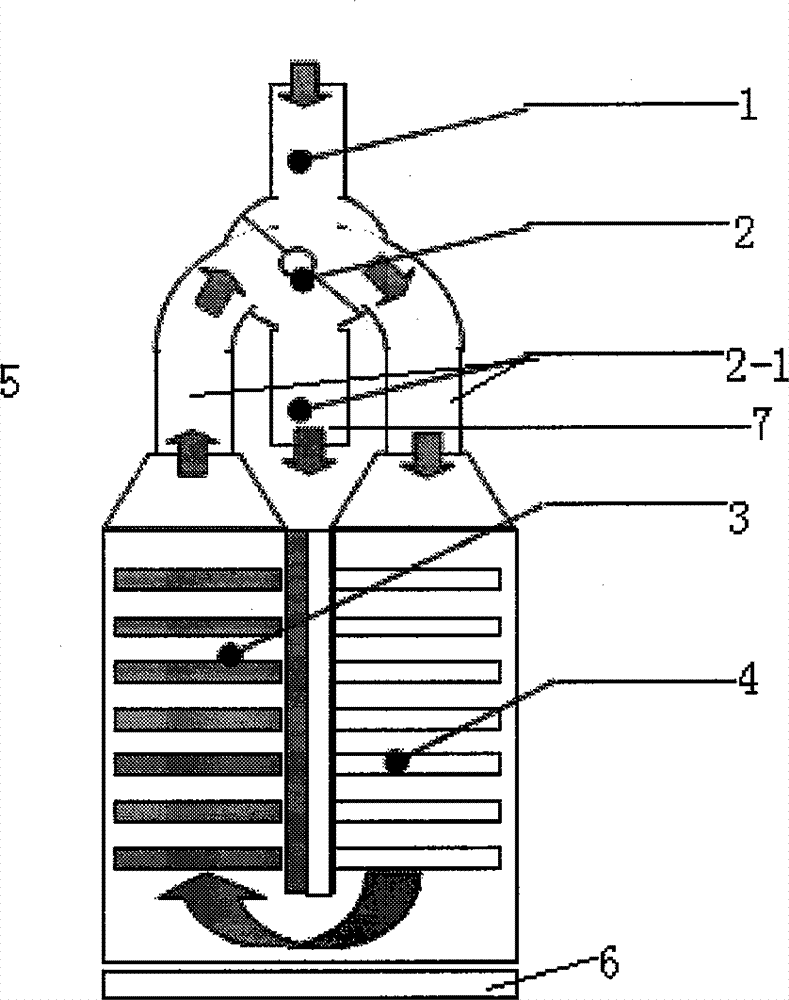

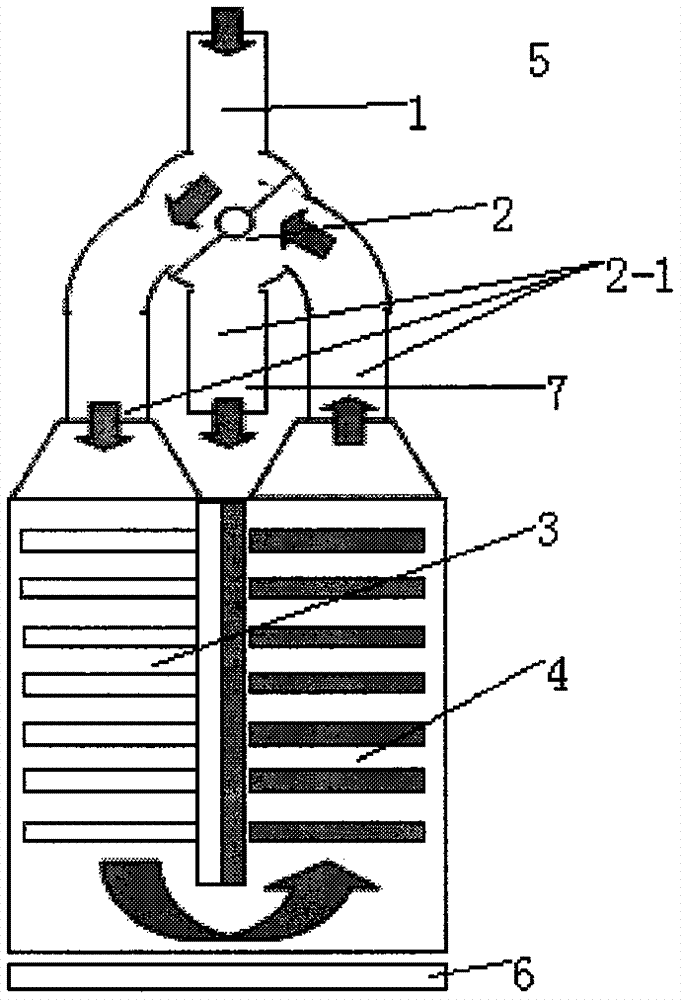

[0040] The heat exchanger (5) includes a gas inlet (1), a four-way valve (2), a first heat exchanger (3), a second heat exchanger (4), a gas outlet (7) and a microwave radiation device (6 ), the four-way valve (2) has four outlets (2-1), one of which is connected to the gas inlet (1), one is connected to the gas outlet (7), and the other two are respectively connected to the first heat exchanger (3) is connected with the second heat exchanger (4), changes the gas flow direction in the heat exchanger (5) through the four-way valve, and the first heat exchanger (3) and the second heat exchanger (4) ) are connected in series, the tubes adopted in the first heat exchanger (3) and the second heat exchanger (4) are microwave permeable tubes, and the method may further comprise the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com