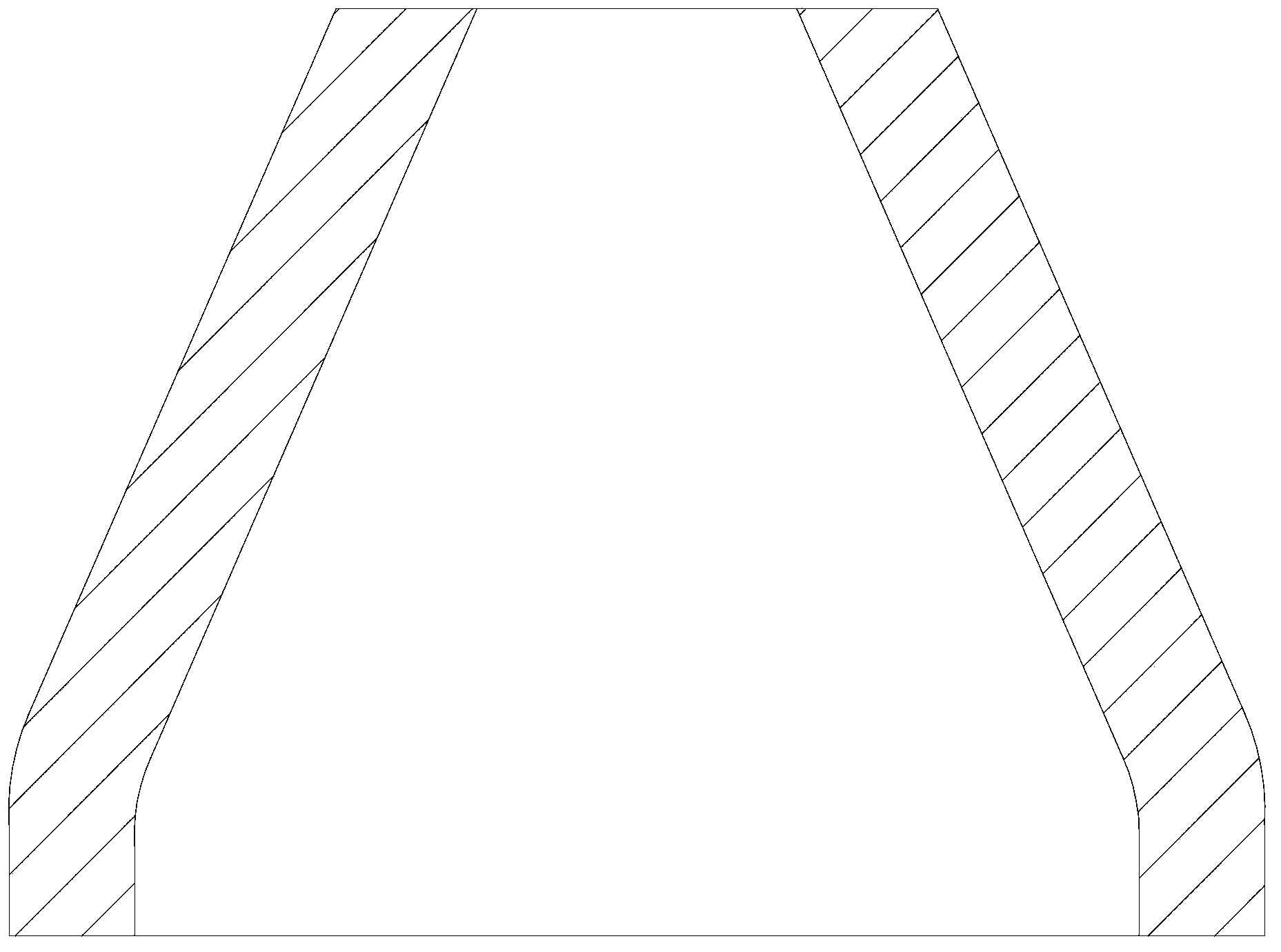

Manufacturing technology for toriconical head

The technology of a conical head and a manufacturing process is applied in the field of the manufacturing process of the folded conical head, which can solve the problems of poor mechanical properties, many processing steps, complicated processes, etc., and achieves high service life, light weight and material saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific embodiments of the present invention are described in detail below.

[0010] The manufacturing process of the folded conical head of the present invention includes the following process steps: a. Refining material: select 6061 aluminum ingot, the mass percentage of each element is silicon: 0.40~0.8, copper: 0.15~0.40, magnesium: 0.8~1.2, Zinc: ≤0.25, Manganese: ≤0.15, Titanium: ≤0.15, Chromium: 0.04~0.35 Iron: 0.000~0.700, the rest is aluminum, of which: single impurity: ≤0.05; total impurity: ≤0.15; The aluminum ingot is smelted in an electric furnace, and then forged into positive and negative electrode rods. Refined aluminum ingots weighing 1.5 tons are upset and drawn three times on a forging machine with a capacity of more than 2,000 tons, so that the composition segregation of the refined aluminum ingots is homogenized to ensure a uniform structure, and then forged into plate-shaped forgings with the required thickness. ≥6, during three upsetting and thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com