Method and device for carrying out gradient utilization on boiler flue gas waste heat to improve efficiency of thermal power unit

A technology for boiler flue gas and thermal power units, which is applied in the directions of preheating, feed water heaters, lighting and heating equipment, etc., can solve the problems of large energy loss, small power generation contribution of the unit, low temperature corrosion, etc., to reduce emissions and reduce temperature. The effect of large and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

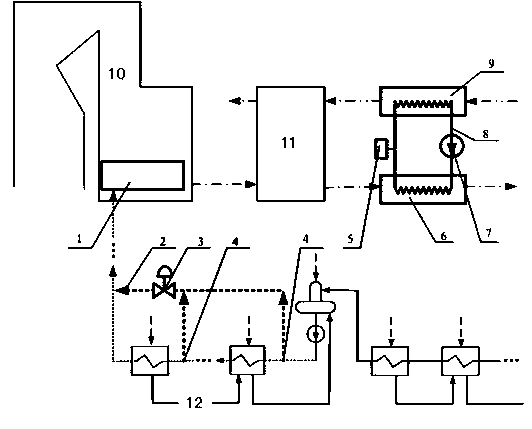

[0024] This cascade uses the waste heat of boiler flue gas to improve the efficiency of thermal power units. An additional heating surface 1 of the economizer is added to the 10th section of the boiler economizer to reduce the temperature of the flue gas entering the air preheater 11 by 15-50°C. Add an air-oil heat exchanger 9 and a flue gas-oil heat exchanger 6 at the cold end of the air preheater 11, and set a circulation pipeline 8 between the flue gas-oil heat exchanger 6 and the air-oil heat exchanger 9 , the expansion tank 5 and the circulation pump 7, and the circulation pipeline 8 is injected with heat transfer medium and heat transfer oil. Through the heat transfer oil, the waste heat of the flue gas is used for the air from the blower before the air preheater 11. Although the temperature of the flue gas entering the air preheater 11 is reduced by 15-50°C, after the air enters the air preheater 11 and is heated by the flue gas, the air temperature can still reach 250-...

Embodiment 2

[0029] This cascade is a device that utilizes boiler flue gas waste heat to improve the efficiency of thermal power units. An additional heating surface 1 is added to the economizer section 10 of the thermal power unit boiler, and an air-oil heat exchanger 9 and flue gas-oil heat exchanger 9 are added to the cold end of the air preheater 11. Oil heat exchanger 6, circulation pipeline 8, expansion tank 5 and circulation pump 7 are set between flue gas heat exchanger-oil 6 and air-oil heat exchanger 9, and heat transfer medium heat transfer oil is injected into circulation pipeline 8 . A bypass pipe 2, a flow regulating valve 3 and a bypass water diversion pipe 4 are provided on the steam turbine side high-pressure heater 12 for the jellyfish pipe.

[0030] The air from the blower enters the air-oil heat exchanger 9, absorbs the heat from the heat transfer medium heat transfer oil of the flue gas heat exchanger 6, and the air is heated to make up for the air preheater 11 due to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com