Cascade-stage-type electron beam diode

A diode and electron beam technology, applied in the direction of X-ray tube electrodes, X-ray tube parts, etc., can solve the problems of insufficient insulation performance, influence of electric field distribution, etc., and achieve the effect of fast movement, guaranteed suspension work, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

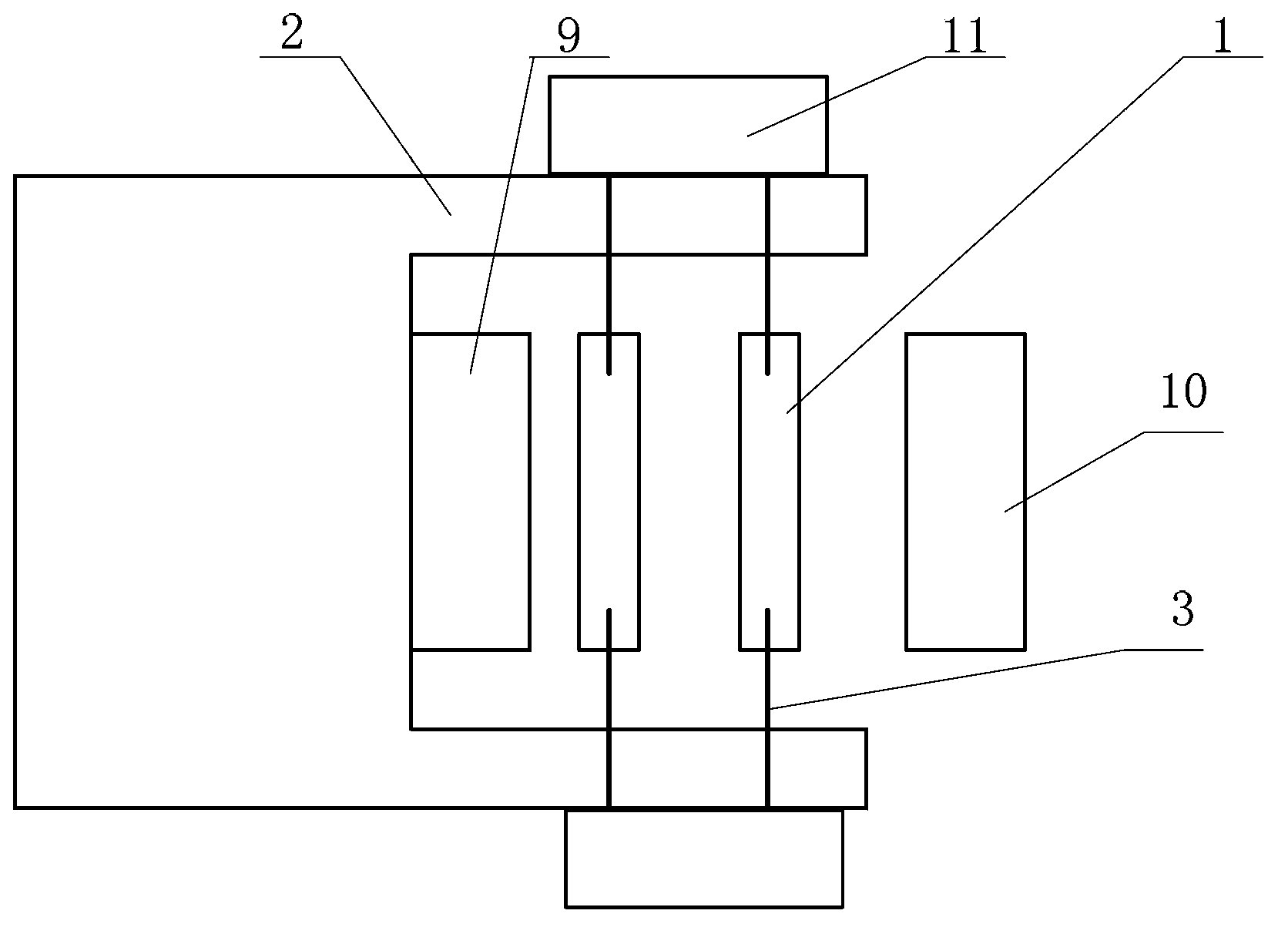

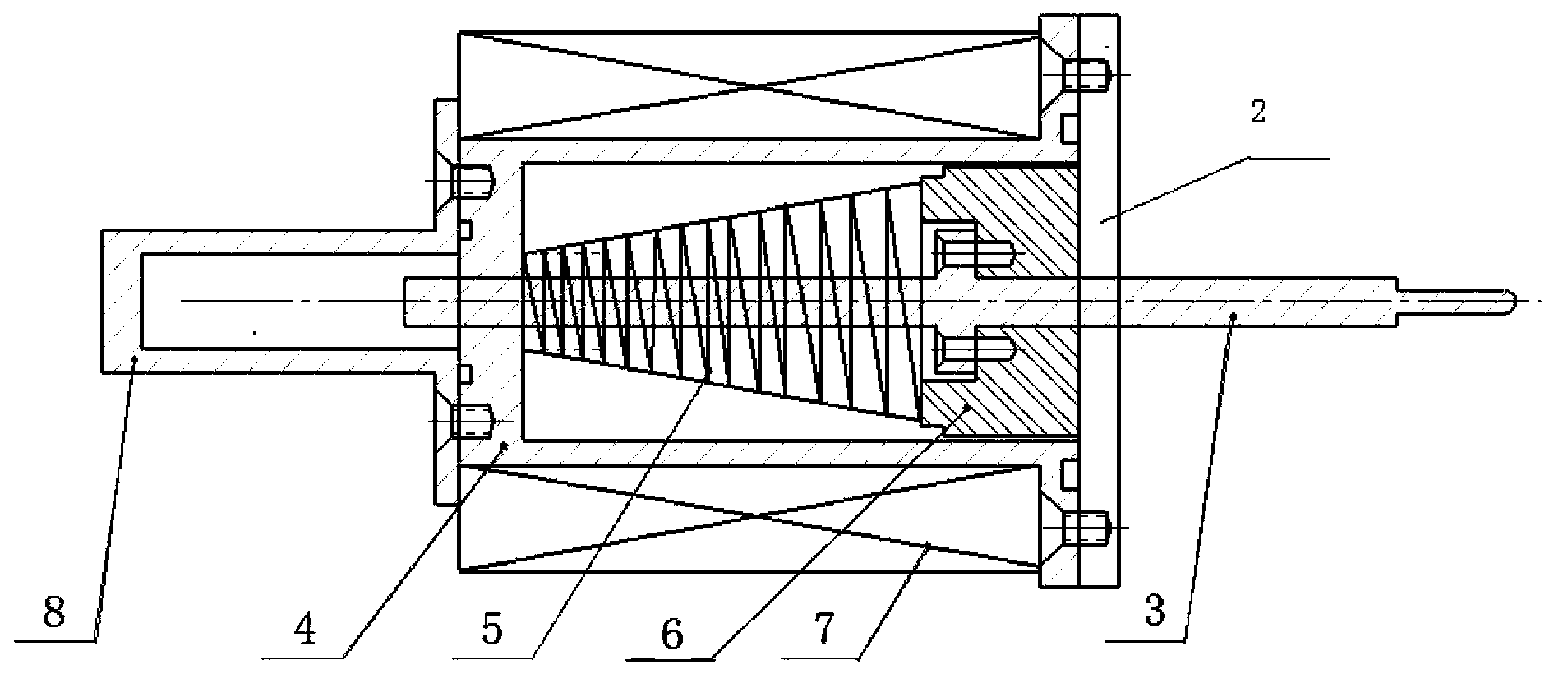

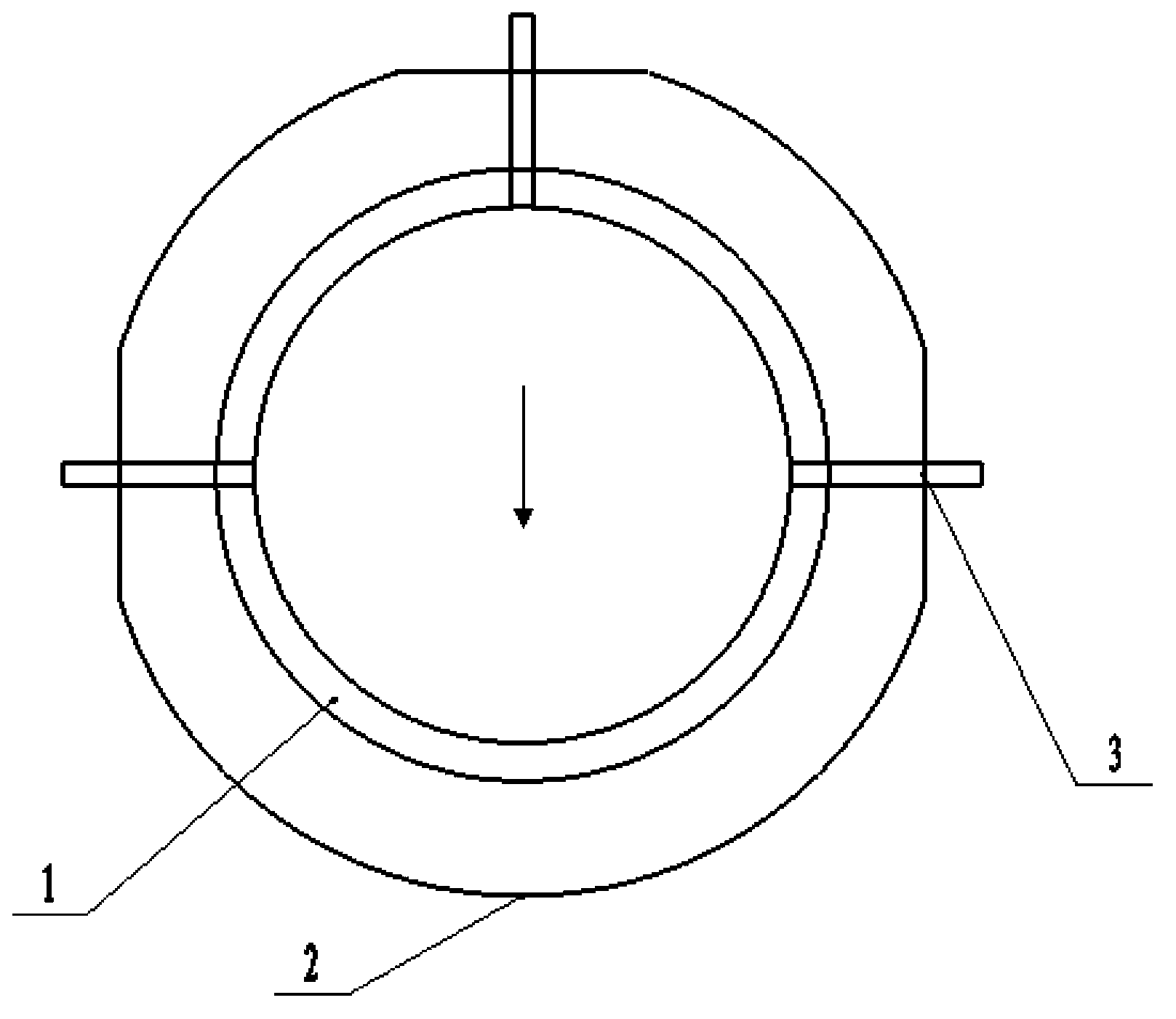

[0030] figure 1 It is a schematic diagram of the principle of the cascaded diode structure of the present invention. There is not less than one floating electrode 1 arranged at a coaxial interval between the cathode 9 and the anode 10 of the conventional electron beam diode. The floating electrode 1 is usually a ring-shaped flat plate with parallel working surfaces. On the working surface of the diode anode 10 and the diode cathode 9, and the centers of the suspension electrode 1, the diode anode 10 and the diode cathode 9 are on a straight line; the suspension electrode 1 is supported by several support devices 11 fixed on the electron beam diode shell, The housing 4 of the supporting device 11 is fixed on the shell 2 of the electron beam diode, and through the support and withdrawal of the supporting pins 3 , the instantaneous floating operation of multiple groups of high-voltage floating electrodes 1 is realized.

[0031] The spacing between the suspension electrodes and be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com