High-protein multi-dimensional puffed saccharified compressed fodder capable of being stored for long time and processing method

A processing method and technology of puffed sugar, applied in animal feed, animal feed, applications, etc., can solve the problems of poor animal feeding effect, space occupied by storage straw, and inconvenient transportation, so as to avoid logistics difficulties and pertinence Good, nutritious and easy to digest and absorb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

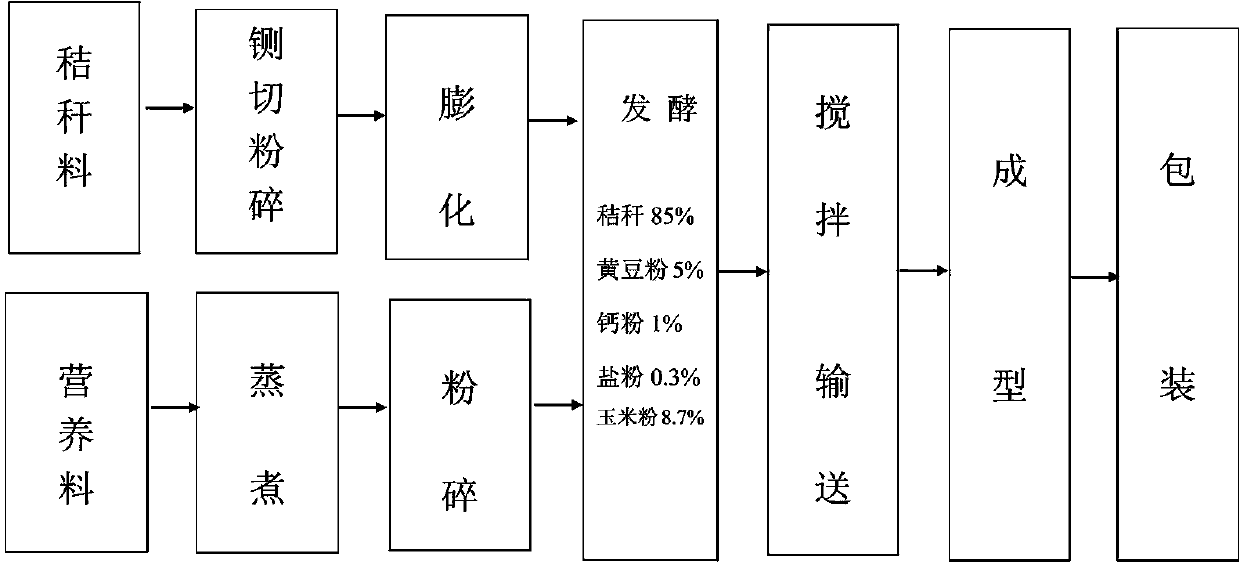

Image

Examples

Embodiment 1

[0039] A processing method for high-protein multi-dimensional puffed, saccharified, and compressed feed for long-term storage. The processing method includes eight steps. The first step is to double-cut and crush the straw, the second step is to puff the crushed straw, and the third step is to puff the puffed straw. The finished straw is fermented, the fourth step is to process the nutrient material, the fifth step is to add the nutrient material, calcium powder and salt to the fermented straw and stir evenly, the sixth step is to send the product of the fifth step into the compression molding machine for granulation, The seventh step is to dry the granular material obtained in the sixth step, and the eighth step is to pack.

[0040] The control power part adopts remote centralized control and is monitored by video. The whole set of production line is compact but not loose, easy to operate, easy to maintain, and runs according to the electric program.

Embodiment 2

[0042] In the processing method of high-protein multi-dimensional extruded saccharification and compressed long-term storage feed described in Example 1, the first step is to double-cut and pulverize the straw to process the straw into a standard length of 5-10mm; The second step to expand the crushed straw is to put the crushed straw into the puffing machine for puffing, and the temperature during puffing is 100°C~120°C; the third step is to ferment the puffed straw Put the puffed straw into the fermentation tank and add 65% of water, then add 1-5% of cellulolytic enzymes to ferment the mycobacterium, so that the decomposed fiber cell wall is fermented to release sugar to make slightly acidic feed.

[0043] Pulverizer is used for crushing: electric mill is used, the power supply is 380v and the power is 1.1kw, and the bottom of the sieve can be replaced at any time according to actual needs.

[0044]Extruder: JPC- The finalized product of straw puffing machine—straight thre...

Embodiment 3

[0046] The processing method of the high-protein multi-dimensional puffed saccharification compressed long-term storage feed described in Example 1, the fourth step of processing the nutritional material is to put soybeans and corn into the pressure cooker, add 70% water and cook for 12 minutes at 2 atmospheric pressures Afterwards, it is sent into a pulverizer and crushed to more than 20 meshes to make a mixture of soybean flour and corn flour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com