Biological deodorizing packing and device

A technology of biological deodorization and biological filler, which is applied in the fields of biological deodorization fillers and devices, materials and devices for waste gas treatment, which can solve the problems of long start-up time, low impact resistance, large floor space, etc., and reduce the adhesion capacity , reduce biological blockage, and break through technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

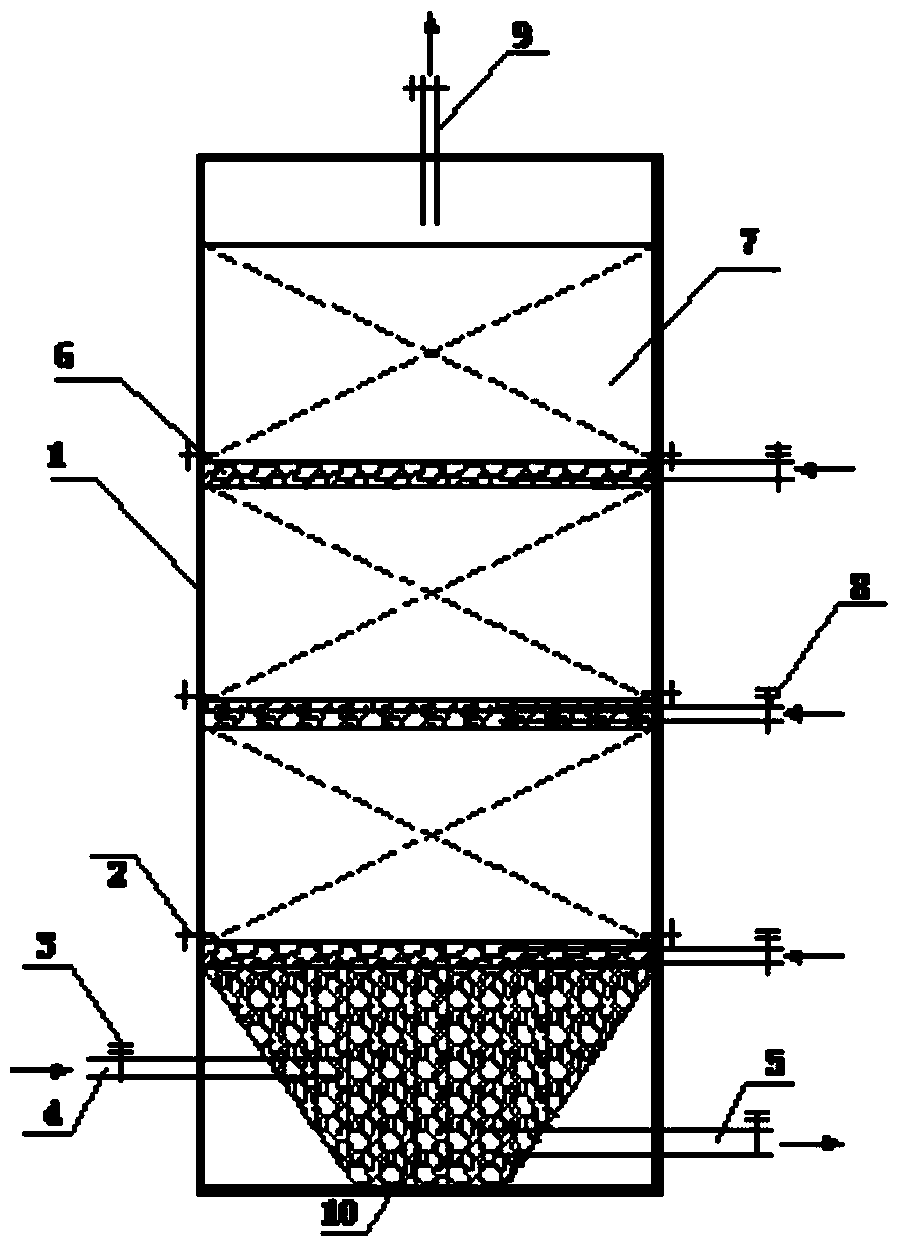

[0038] Example 1, constructing a biological deodorization system for malodorous gases.

[0039] First, biochar, mineralized waste and incineration ash are mixed into a biological deodorizing filler with a mass ratio of biochar:mineralized waste:polyurethane of 3:4:3, and the packing density of the biological deodorizing filler after mixing evenly 0.6g / cm 3 , the particle size range is 5-50mm, and the specific surface area is 300m 2 / g; the biochar is made by anaerobic / anoxic pyrolysis process using the remaining sludge of Minhang Sewage Treatment Plant in anaerobic or anoxic state at 600°C, and the mineralized waste is taken from Laogang Fill Landfill garbage (particle size <50mm) for 6 years, polyurethane is irregular block, particle size is 20mm.

[0040] Then the above-mentioned biological deodorization filler is added to the structure as described above (such as figure 1 and figure 2 shown) in the biological deodorization device. This biological deodorization device ...

Embodiment 2

[0042] Example 2, constructing a biological deodorization system for malodorous gases.

[0043] First, biochar, mineralized waste and incineration ash are mixed into a biological deodorizing filler with a mass ratio of biochar:mineralized waste:polyurethane of 4:5:1, and the packing density of the biological deodorizing filler after mixing evenly 1.0g / cm 3 , the particle size range is 5-50mm, and the specific surface area is 200m 2 / g; the biochar is made by anaerobic / anoxic pyrolysis process using the remaining sludge of Minhang Sewage Treatment Plant in anaerobic or anoxic state at 600°C, and the mineralized waste is taken from Laogang Fill Landfill 15 years of garbage (particle size <50mm), polyurethane is irregular block, particle size is 30mm.

[0044] Then the above-mentioned biological deodorization filler is added to the structure as described above (such as figure 1 and figure 2shown) in the biological deodorization device. This biological deodorization device c...

Embodiment 3

[0046] Example 3, constructing a biological deodorization system for malodorous gases.

[0047] First, biochar, mineralized waste and incineration ash are mixed into a biological deodorizing filler with a mass ratio of biochar: mineralized waste: polyurethane of 3:5:2, and the packing density of the biological deodorizing filler after mixing evenly 0.8g / cm 3 , the particle size range is 5-50mm, and the specific surface area is 270m 2 / g; the biochar is made by anaerobic / anoxic pyrolysis process using the remaining sludge of Minhang Sewage Treatment Plant in anaerobic or anoxic state at 750°C, and the mineralized waste is taken from Laogang Fill Landfill garbage (particle size <40mm) for 10 years, polyurethane is irregular block, particle size is 50mm.

[0048] Then the above-mentioned biological deodorization filler is added to the structure as described above (such as figure 1 and figure 2 shown) in the biological deodorization device. This biological deodorization devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com