Ceramic base carbon nano tube inorganic composite membrane and preparation method thereof

An inorganic composite membrane and carbon nanotube technology, which is applied in the field of membrane separation, can solve the problems of porosity loss and low carbon membrane porosity, and achieve high porosity, ensure electrical properties, and effectively remove the effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

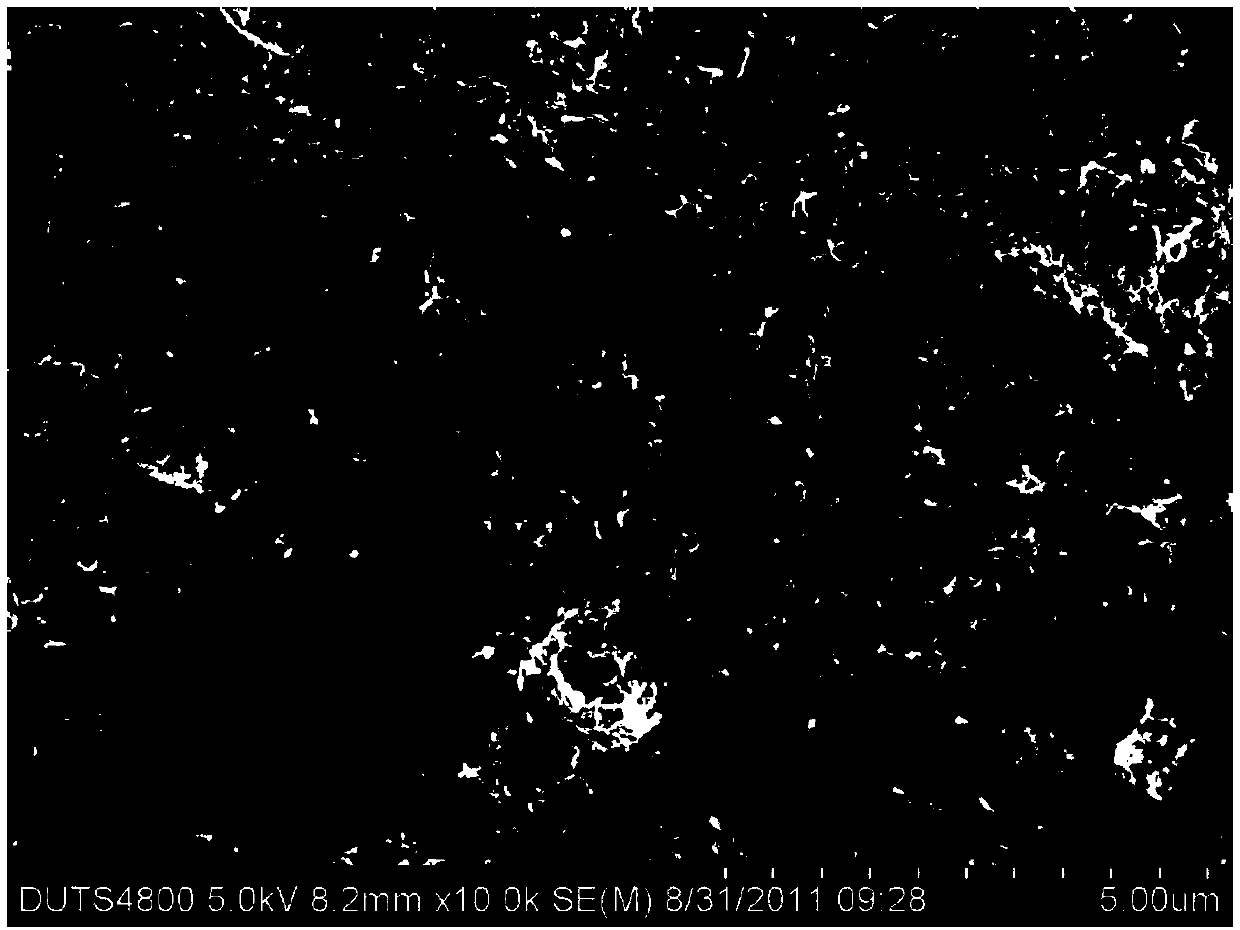

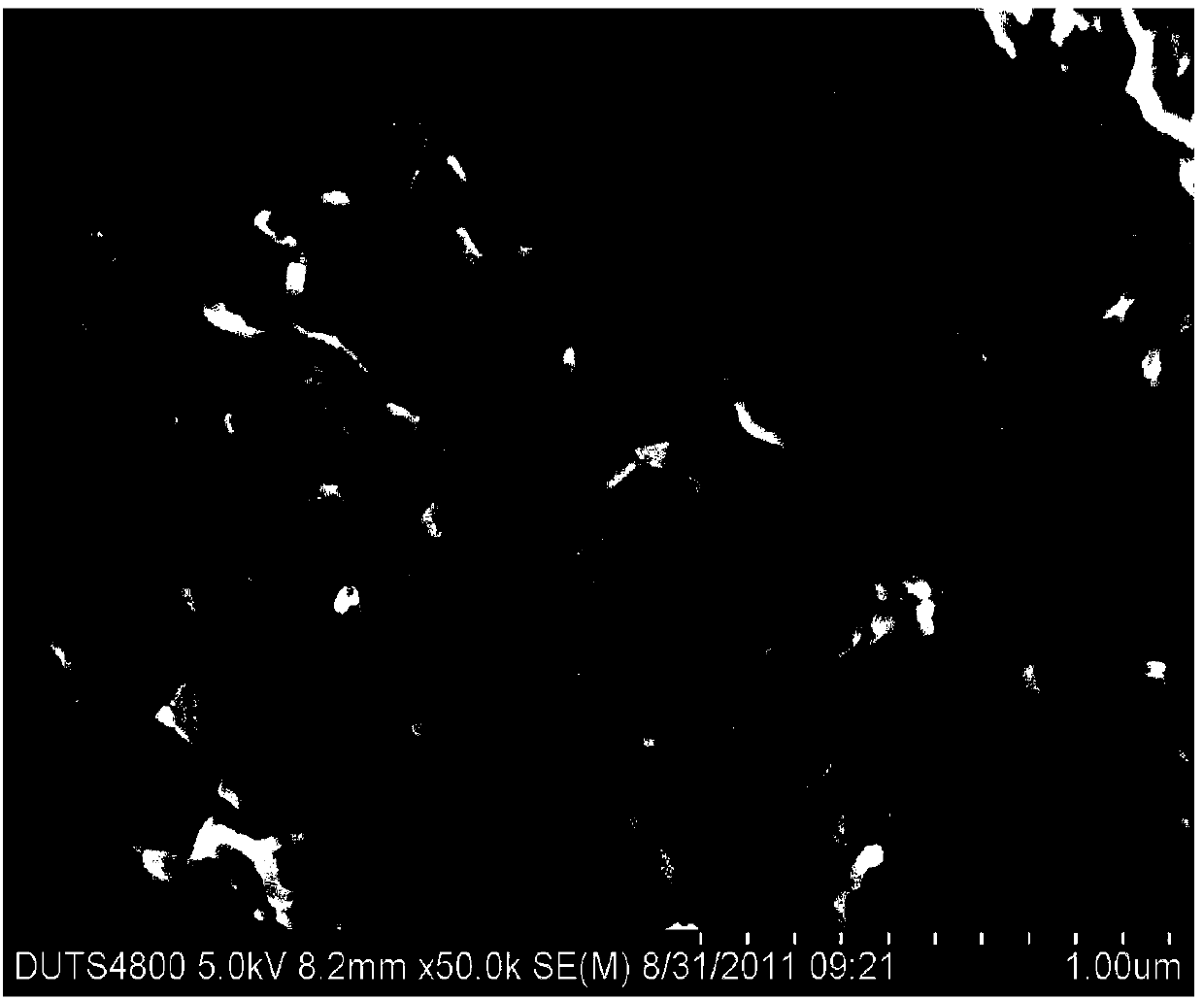

Image

Examples

Embodiment 1

[0027] Example 1 A ceramic-based carbon nanotube composite flat ultrafiltration membrane with a small pore size was prepared.

[0028] Using a flat ZrO plate with a pore size of 200 nm 2 The ceramic membrane is used as a carrier to prepare a single-wall ceramic-based carbon nanotube composite flat ultrafiltration membrane with a pore size of <5nm. The steps are:

[0029] The first step, the pretreatment of the carrier

[0030] ZrO will be used as carrier 2 The volume ratio of the ceramic membrane is H 2 SO 4 :H 2 o 2 =3:1 Washing solution is subjected to impurity removal treatment at 80°C for 1 hour, then rinsed with deionized water until neutral, and dried for later use;

[0031] The second step, preparation of single-walled carbon nanotube dispersion

[0032] Using a surfactant-assisted method to disperse the single-walled carbon nanotubes in a 5-10wt% sodium dodecyl sulfate solution, and ultrasonically disperse to form a single-walled carbon nanotube dispersion with ...

Embodiment 2

[0036] Example 2 A ceramic-based carbon nanotube composite tubular microfiltration membrane with a large pore size was prepared.

[0037] A tubular alumina ceramic membrane with a pore size of 2000-3000 nm is used as a carrier to prepare a single-wall ceramic-based carbon nanotube composite tubular microfiltration membrane with a pore size of 140 nm. The steps are:

[0038] The first step, the pretreatment of the carrier

[0039] The tubular alumina ceramic membrane as the carrier is used with a volume ratio of H 2 SO 4 :H 2 o 2 =3:1 washing solution is subjected to impurity removal treatment at 70°C for 2 hours, then rinsed with deionized water until neutral, and dried for later use;

[0040] The second step, preparation of multi-walled carbon nanotube dispersion

[0041] First, the multi-walled carbon nanotubes with a diameter of 40-60nm are passed through a volume ratio of H 2 SO 4 :HNO 3 =3:1 acid solution was treated at 60°C for 8 hours, washed with deionized wate...

Embodiment 3

[0045] Example 3 Preparation of ceramic-based carbon nanotube composite tubular ultrafiltration membrane with medium pore size

[0046] A ceramic-based carbon nanotube composite tubular ultrafiltration membrane with a pore size of 60 nm is prepared by using an alumina tubular ceramic membrane with a pore size of 600 to 1000 nm as a carrier. The steps are:

[0047] The first step, the pretreatment of the carrier

[0048] The tubular alumina ceramic membrane as the carrier is used with a volume ratio of H 2 SO 4 :H 2 o 2=3:1 Washing solution is subjected to impurity removal treatment at 80°C for 1 hour, then rinsed with deionized water until neutral, and dried for later use;

[0049] The second step, preparation of multi-walled carbon nanotube dispersion

[0050] First, the multi-walled carbon nanotubes with a diameter of 10-20nm are passed through a volume ratio of H 2 SO 4 :HNO 3 =3:1 acid solution was treated at 60°C for 8 hours, washed with deionized water until neut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com