Method for preparing nanometer copper through chemical reduction method

A technology of nano-copper powder and reducing agent, which is applied in the field of preparing nano-copper by chemical reduction method, which can solve the problems that the active metal powder reducing agent is not easy to clean and affects the purity of nano-copper powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

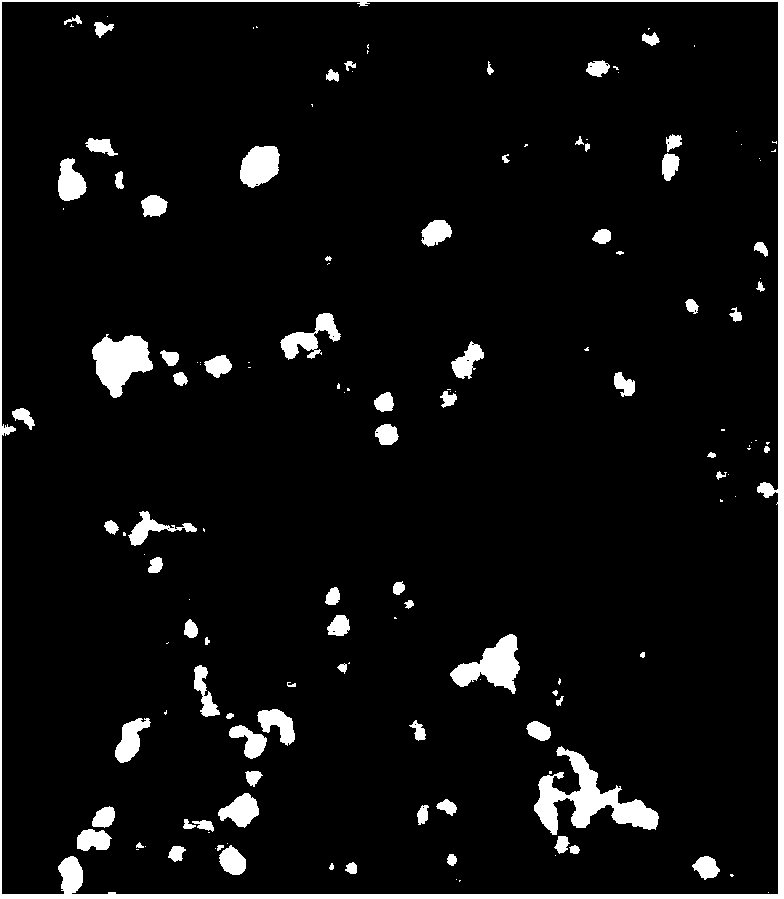

Image

Examples

Embodiment 1

[0017] The preparation of nano copper powder is carried out according to the following steps:

[0018] (1) Dissolve 10g of copper sulfate in 300ml of deionized water, add 5g of polyacrylic acid, stir to dissolve it, and then add 150ml of ammonia water with a concentration of 25% to form a dark blue aqueous solution of tetraammonia copper complex ions

[0019] (2) Dissolve 5g of sodium hypophosphite in 20ml of water to obtain a homogeneous solution

[0020] (3) Pour solution (2) into (1). Stirring was continued, resulting in a precipitate, until the solution became colorless

[0021] (4), stop stirring and let it stand, remove the supernatant

[0022] (5) Wash twice with ethanol

[0023] (6) Treat the cleaned precipitate in (5) at 100°C for 10 hours under a nitrogen atmosphere to obtain nano-copper powder

[0024] The advantages of the present invention are:

[0025] (1) The present invention has high reduction efficiency and high recovery rate, and the nanometer particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com