Novel metal plate strip surface cleaning method and device

A metal strip, surface cleaning technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problem that the uniformity of cleaning is difficult to be guaranteed, the stability of the use effect of the brush roller is affected, and the hard particles are easy to fall off. and other problems, to achieve the effect of quality and metal yield, improved environmental and pollution control, good flatness and finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

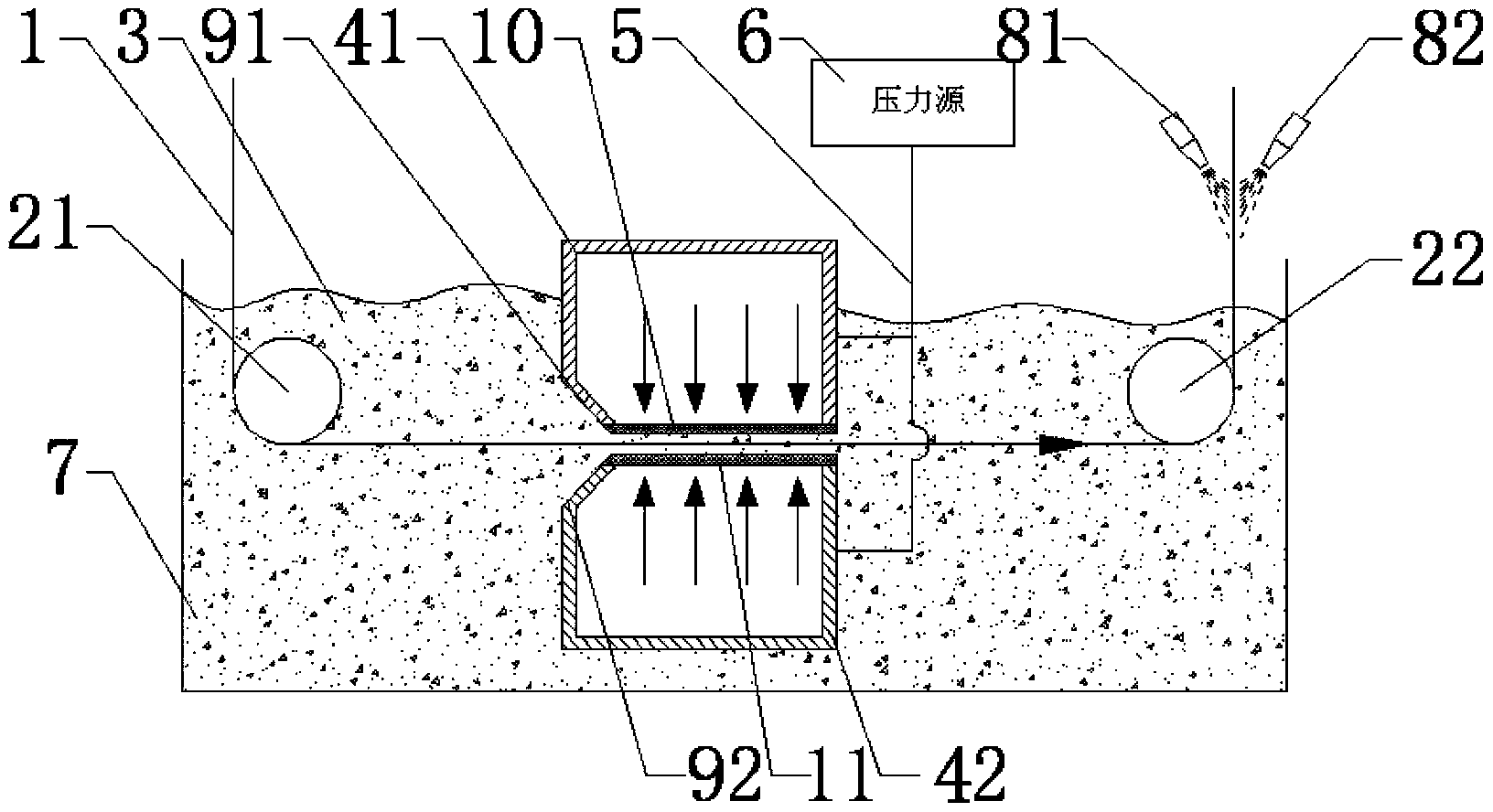

[0050] As mentioned above, the method of the present invention is to comprehensively utilize the soft material to carry out pressure friction on the metal surface, relying on the role of the grinding mud as the intermediate medium to realize the removal of the scales on the surface of the metal strip, the specific implementation method is as follows figure 1 shown.

[0051] The novel metal strip surface cleaning method and device of the present invention can be described as having two pressure boxes 41, 42 arranged up and down, wherein the lower surface of the upper pressure box 41 is a soft, wear-resistant surface 10, and the upper pressure box 42 The upper surface of the upper pressure box 41 is a soft, wear-resistant surface 11, and the materials of the upper and lower surfaces 10, 11 are completely the same; at the same time, the inlet area of the lower surface 10 of the upper pressure box 41 is provided with an inlet inclined guide plate 91, and at the same time, the upp...

Embodiment 2

[0061] According to the present embodiment, roughly as embodiment 1, but following is difference:

[0062] The upper and lower pressure tanks 41, 42 have a fluid medium inside, and the medium is gas or liquid oil, and the fluid medium is transported to the upper and lower pressure tanks 41, 42 through the pressure source 6 and the pressure delivery pipeline 5 , and realize regulating and maintaining the pressure levels in the upper and lower pressure tanks 41 and 42.

[0063] Preferably, the particle size range of the sandy hard abrasive particles is between 50 mesh and 80 mesh.

[0064] The inclination angle of the inclined guide plate is between 4° and 6°.

[0065] This embodiment uses non-metallic bristles. The non-metallic bristles are polymer materials, and hard abrasive particles such as hard emery are adhered on the surface of the bristles.

[0066] Under the pressure of 2-3MPa, the lower surface 10 of the upper pressure box 41 and the upper surface 11 of the lower p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com