Method for removing ammonia nitrogen by three-dimensional electrode

A three-dimensional electrode, ammonia nitrogen technology, used in sterilization/microdynamic water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of limited ammonia nitrogen exchange capacity and cumbersome operation process, so as to improve the ammonia nitrogen removal capacity and current. Efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

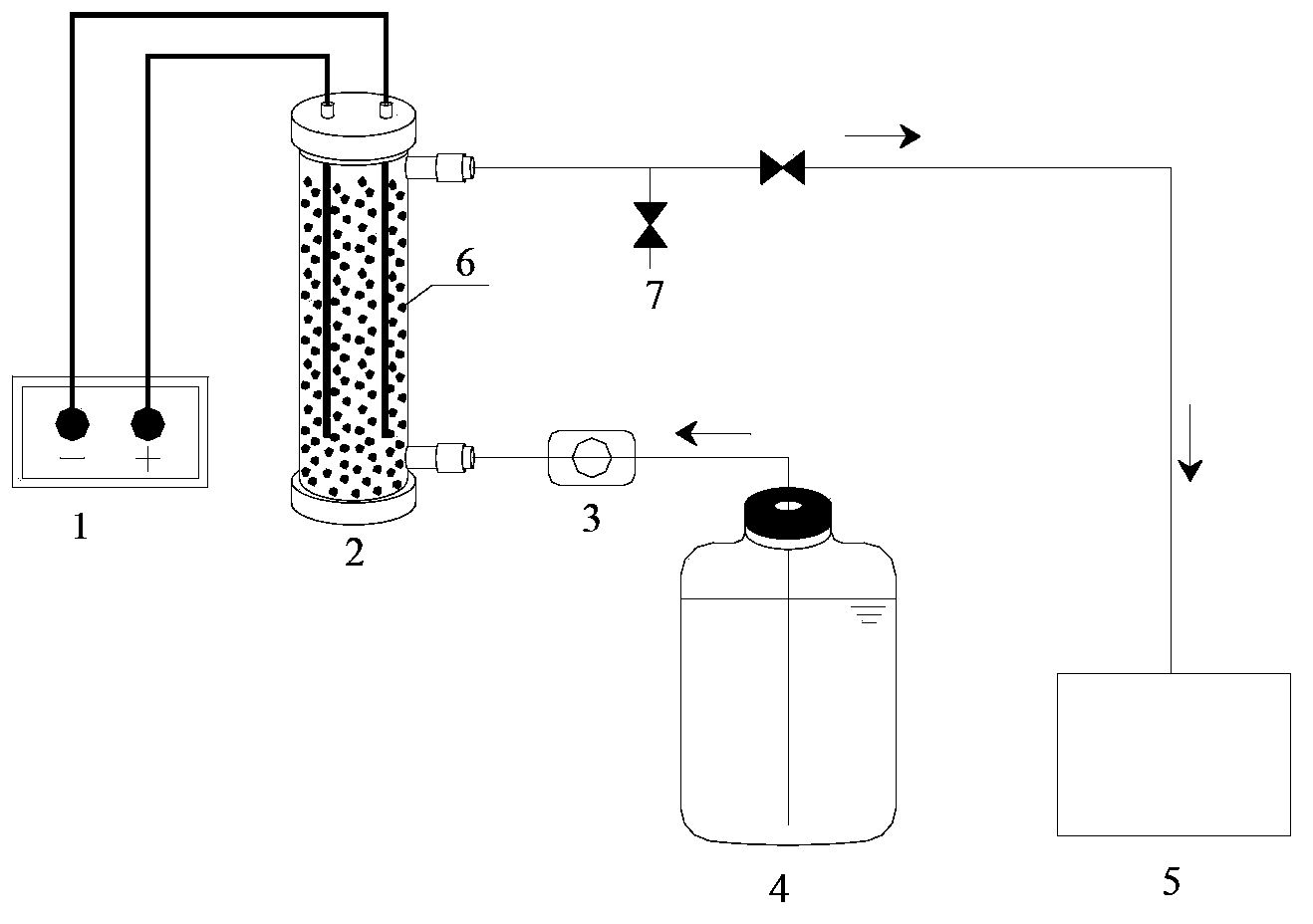

[0026] figure 1 It is a schematic diagram of the device structure of the three-dimensional electrode ammonia nitrogen removal method of this embodiment.

[0027] The device for removing ammonia nitrogen by the three-dimensional electrode in the present embodiment, such as figure 1 As shown, it includes: an electrolytic cell 2 for treating wastewater; a peristaltic pump 3 for delivering wastewater to the electrolytic cell; a water collection tank 5 for collecting treated wastewater; a DC power supply 1 for supplying power to the electrolytic cell 2; And waste water tank 4, used for storing waste water containing ammonia nitrogen. Wherein, the cathode of the three-dimensional electrode in the electrolytic cell 2 and the top of the anode are connected to a DC power supply, and the anode is Ti / RuO 2 , the cathode is a stainless steel plate, the particle electrode of the three-dimensional electrode is natural clinoptilolite 6, and the particle diameter of natural clinoptilolite 6...

Embodiment 2

[0043] Preparation of a certain amount of ammonia nitrogen and chloride ion concentration is respectively 24.0mg N / L, 300mg / L waste water is packed in waste water tank 4, utilizes the NaOH solution of 1mol / L and the H of 0.5mol / L 2 SO 4 The solution adjusts the pH of the water sample to 7, using Na 2 SO 4 Adjust conductivity to 1500 μS / cm.

[0044] A method for removing ammonia nitrogen from water using a three-dimensional electrode, comprising the following steps:

[0045] Such as figure 1 As shown, connect the device;

[0046] Open the peristaltic pump, waste water is sent into described electrolytic cell, control peristaltic pump rotating speed is 5rpm, and the hydraulic retention time of waste water in electrolytic cell is 31min this moment;

[0047] Before powering on, feed enough waste water containing ammonia nitrogen into the electrolytic cell until the concentration of ammonia nitrogen in the effluent is consistent with that of the influent water, so that the zeo...

Embodiment 3

[0054] Preparation of a certain amount of ammonia nitrogen and chlorine ion concentration is respectively 25.0mg N / L, 300mg / L waste water is packed in waste water tank 4, utilizes the NaOH solution of 1mol / L and the H of 0.5mol / L 2 SO 4 The solution adjusts the pH of the water sample to 7, using Na 2 SO 4 Adjust the conductivity to 1500μS / cm;

[0055] A method for removing ammonia nitrogen from water using a three-dimensional electrode, comprising the following steps:

[0056] Such as figure 1 As shown, connect the device;

[0057] Turn on the peristaltic pump, waste water is sent into described electrolyzer, control peristaltic pump rotating speed is 9rpm, and now the hydraulic retention time of waste water in electrolyzer is 16min;

[0058] Before powering on, feed enough waste water containing ammonia nitrogen into the electrolytic cell until the concentration of ammonia nitrogen in the effluent is consistent with that of the influent water, so that the zeolite in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com