A kind of method for preparing methylcyclopentene

A technology for methylcyclopentene and methylcyclopentadiene, which is applied in the field of preparing methylcyclopentene, can solve the problems of low methylcyclopentene yield, high energy consumption, complicated process and the like, and achieves reduction of equipment. The effect of investment, reduction of operating costs, and simplification of separation and purification systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

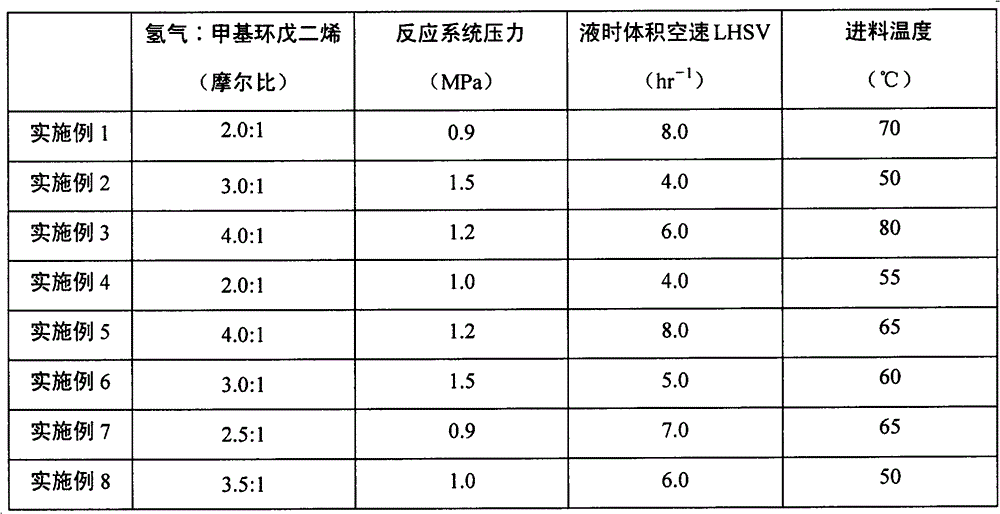

[0025] Fill the catalyst in the fixed bed reactor, the catalyst is γ-Al 2 o 3 It is used as a carrier, Pd is used as an active component, and the content of Pd in the catalyst is 0.3-1.0 wt%. The solvent, methylcyclopentadiene obtained by thermal cracking of dimethylcyclopentadiene, and hydrogen were mixed and then continuously passed through the reactor for hydrogenation reaction. The hydrogenation reaction conditions of each example are shown in Table 1. The contents of methylcyclopentadiene, methylcyclopentene and methylcyclopentane in the hydrogenation products were determined by gas chromatography, and the conversion rate of methylcyclopentadiene, methylcyclopentene and methylcyclopentene were calculated. The selectivity of pentane, the results are shown in Table 2.

[0026] Table 1.

[0027]

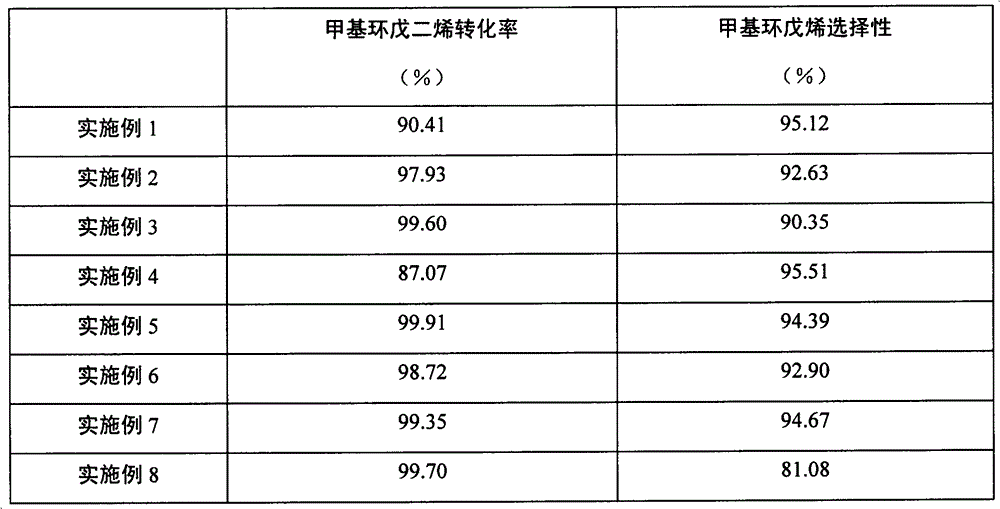

[0028] Table 2.

[0029]

Embodiment 9~18

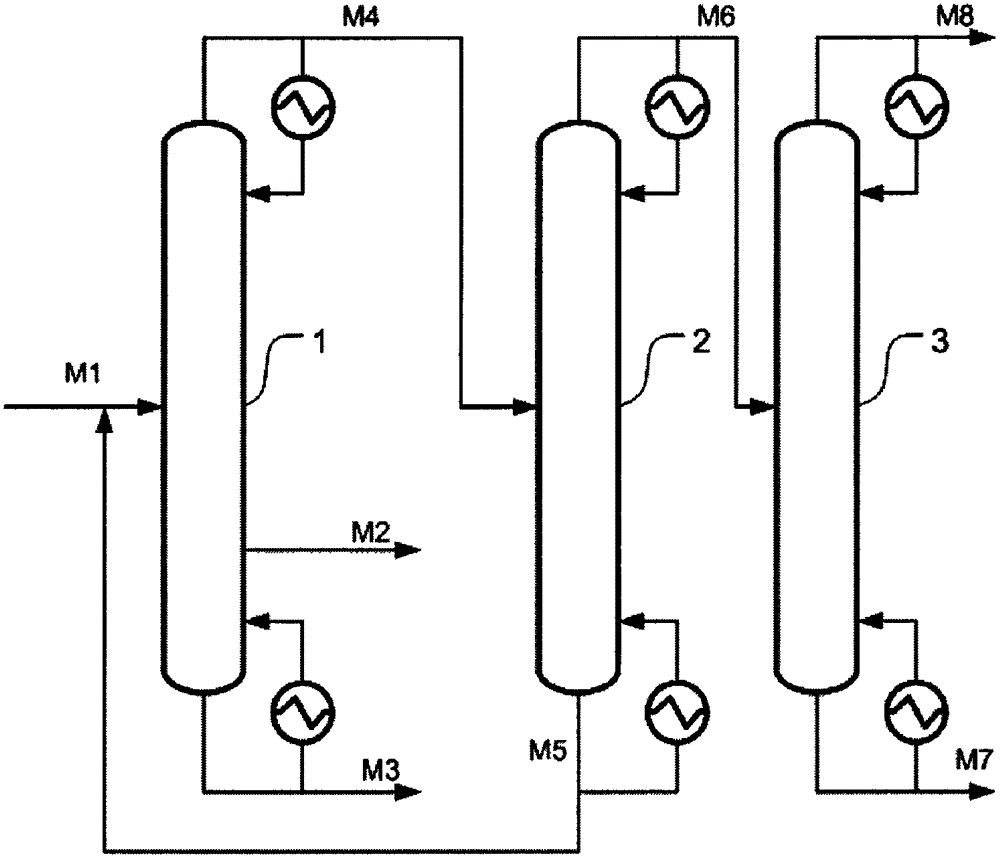

[0031] The hydrogenation products obtained in Examples 1-8 are mixed and then separated and refined. The process flow is shown in the accompanying drawings.

[0032] The operating conditions of rectification tower 1, rectification tower 2, and rectification tower 3 are shown in Table 3, the refined methylcyclopentane purity that rectification tower 1 side line obtains, the refined methylcyclopentene that rectification tower 3 tower kettle obtains Purity, methylcyclopentene yield are shown in Table 4.

[0033] table 3.

[0034]

[0035] Table 4.

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com