Open-type constant-current diffusion protein crystallization array chip and manufacturing method thereof

A protein crystallization and array chip technology, which is applied in the biological field, can solve the problems of difficulty in promoting the crystallization of protein molecules, the total amount of protein molecules is limited, and the size of protein crystals is small. The effect of large crystal size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

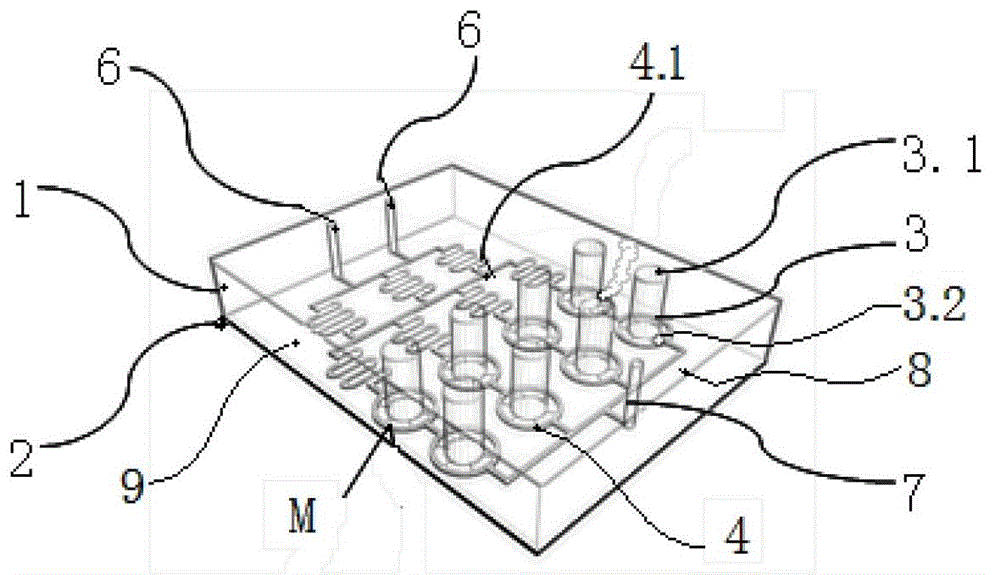

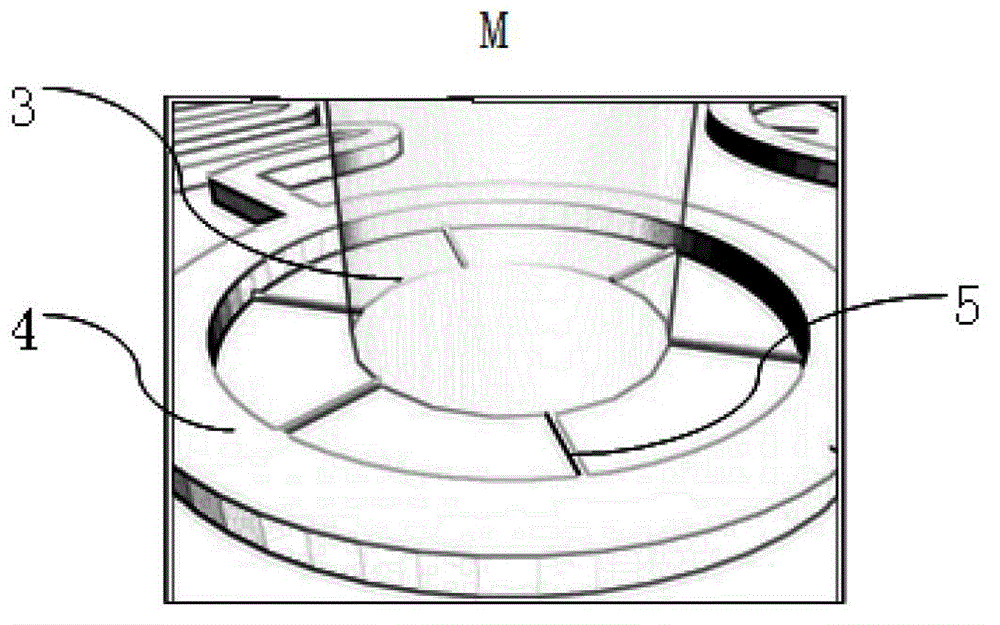

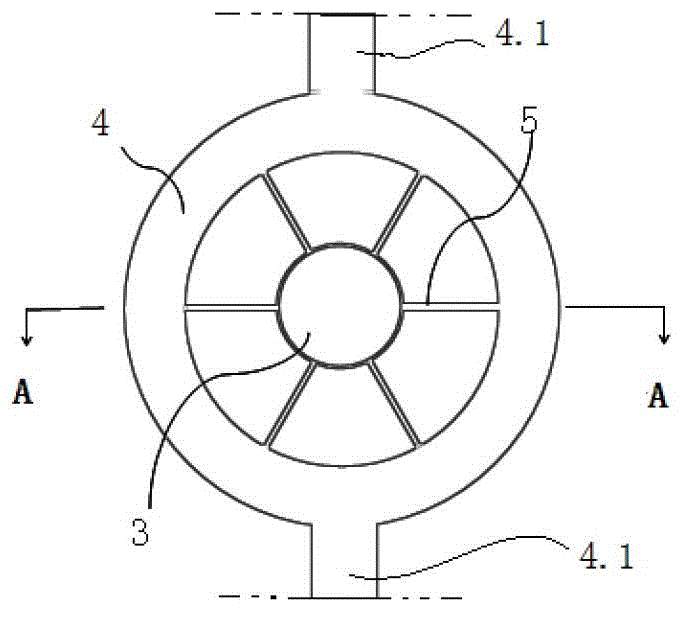

[0051] Embodiment 1: It is the basic embodiment of the present invention. like Figure 1-5 As shown, an open constant current diffusion protein crystallization array chip, which includes a substrate 2 and a substrate 1 fixed on the substrate 2; several cylindrical hole-shaped protein crystallization units 3 are distributed on the substrate 1; One end of each protein crystallization unit 3 has an upper opening 3.1 facing upwards, and the other end has a lower opening 3.2 facing the surface of the substrate 2; the plane where the substrate 1 and the base 2 are combined has a ring surrounding the lower opening 3.2 of the protein crystallization unit 3 The microfluidic main channel 4; the annular microfluidic main channel 4 communicates with the protein crystallization unit 3 through several microfluidic diffusion channels 5; the two ends of the substrate 1 respectively have the protein solution connected with the annular microfluidic main channel 4 Inlet 6 and outlet 7; severa...

Embodiment 2

[0052] Example 2: It is an embodiment of the single row crystal unit array in the above-mentioned embodiment 1. The open constant current diffusion protein crystallization array chip is composed of 4 annular microfluidic main channels 4 connected in series through the connecting channel 4.1 along the direction from one inlet 6 to the other outlet 7 and together with the protein crystallization unit 3 in the middle constitutes a Single Column Crystalline Cell Array 12.1. The upper port 3.1 is an open orifice communicating with the external environment, and is used for regulating the humidity required for crystallization in the protein crystallization unit 3 and for injecting a precipitation solution into the protein crystallization unit 3 . The microfluidic diffusion channel 5 is on the plane where the substrate 1 and the substrate 2 are combined, or in the middle of the substrate 1 . The annular microfluidic main channel 4 is circular or polygonal; the microfluidic diffusio...

Embodiment 3

[0054] Example 3: The difference from the above-mentioned embodiment 2 is that this embodiment is an embodiment of a multi-row crystal unit array. The open constant current diffusion protein crystallization array chip consists of two single-row crystallization unit arrays 12.1 connected in parallel to form a multi-row crystallization unit array 12.2. The two single-row crystallization unit arrays 12.1 of the multi-row crystallization unit array 12.2 have one inlet 6 and one outlet 7 in total.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com