Reaction type greasy base degradable surfactant as well as synthetic method and application thereof

A technology of surfactant and synthesis method, which is applied in the direction of fatty acid production, fatty acid chemical modification, fatty acid preparation/refining, etc., can solve the problems of unsuitable industrial application and high cost, and achieves industrial promotion of emulsion polymerization, low price, and easy availability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

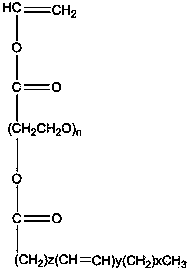

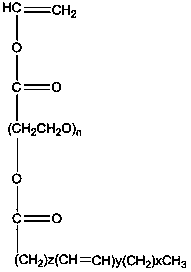

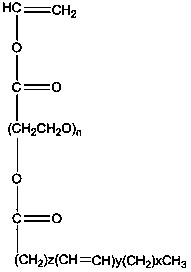

[0024] A kind of synthetic method of grease-based degradable surfactant provided by the invention comprises the following steps:

[0025] 1. Hydrolyzing oil: Mix 50 parts by mass of an acid catalyst with a mass concentration of 15-35% and 30-70 parts by mass of ethanol evenly, add it to the reactor, heat up to 50-100°C, and stir for 0.5-12 hours Add 20-60 parts of fats and oils to the reactor dropwise, keep warm for 0.5-24 hours, cool to room temperature, let stand to separate layers, take the upper layer and wash it with water for 5 times to obtain fatty acid;

[0026] 2. Esterification of fatty acid and polyether: dissolve 30-100 parts by mass of the fatty acid obtained in step 1 and the polyether in equal molar parts to the fatty acid in 100 parts by mass of toluene, add it to the reactor, and drop in 0.01-0.5 parts by mass of acid Catalyst, heat up to 50-150°C while stirring, stir and react for 0.5-24 hours, after the reaction is completed, vacuumize toluene at 50-100°C, a...

Embodiment 1

[0041] Preparation of oil-based degradable surfactant

[0042] 1. Hydrolyzing oil: Mix 50 grams of 15% sulfuric acid and 30 grams of ethanol evenly, add it into the reactor, raise the temperature to 60°C, and drop 20 grams of soybean oil into the reactor within 1 hour while stirring , heat preservation reaction for 2 hours, then cool to room temperature, after the reaction is completed, let stand to separate layers, take the supernatant and wash 5 times with water to obtain fatty acid;

[0043] 2. Esterification of fatty acid and polyether: dissolve 30 grams of fatty acid obtained in step 1 and polyether with an equal molar fraction of fatty acid in 100 grams of toluene, add to the reactor, add 0.01 gram of concentrated sulfuric acid dropwise, and heat up to 60°C, stirred for 1 hour, after the reaction was completed, vacuumed at 60°C to remove toluene, and then added dropwise NaHCO with a mass fraction of 30%. 3 aqueous solution until no more bubbles are formed. Then add 60 ...

Embodiment 2

[0048] Preparation of oil-based degradable surfactant:

[0049] 1. Hydrolyzed oil: Mix 50 grams of hydrochloric acid with a mass concentration of 20% and 50 grams of ethanol evenly, add it into the reactor, raise the temperature to 70°C, and add 50 parts of lard dropwise to the reactor within 4 hours while stirring , heat preservation reaction for 2 hours, then cool to room temperature, after the reaction is completed, let stand to separate layers, take the upper layer and wash with water 5 times to obtain fatty acid;

[0050] 2. Esterification of fatty acid and polyether: dissolve 30 grams of fatty acid obtained in step 1 and polyether in equal molar fractions with fatty acid in 100 parts of toluene, add to the reactor, add 0.1 gram of concentrated sulfuric acid dropwise, and heat up to 90°C, stirred and reacted for 2 hours, after the reaction was completed, vacuumed at 60°C to remove toluene, and then added dropwise NaHCO with a mass fraction of 30% 3 aqueous solution until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com