Nano catalytic viscosity reducer for thickened oil aqua-thermolysis and preparation method thereof

A technology of nano-catalysis and viscosity reducer, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of reduced catalytic activity of super-acid catalysts in contact with water, difficulty in field promotion and application, and poor contact with crude oil, etc., to achieve Viscosity reduction, good viscosity reduction effect, and the effect of increasing the hydrogen-to-carbon atomic ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

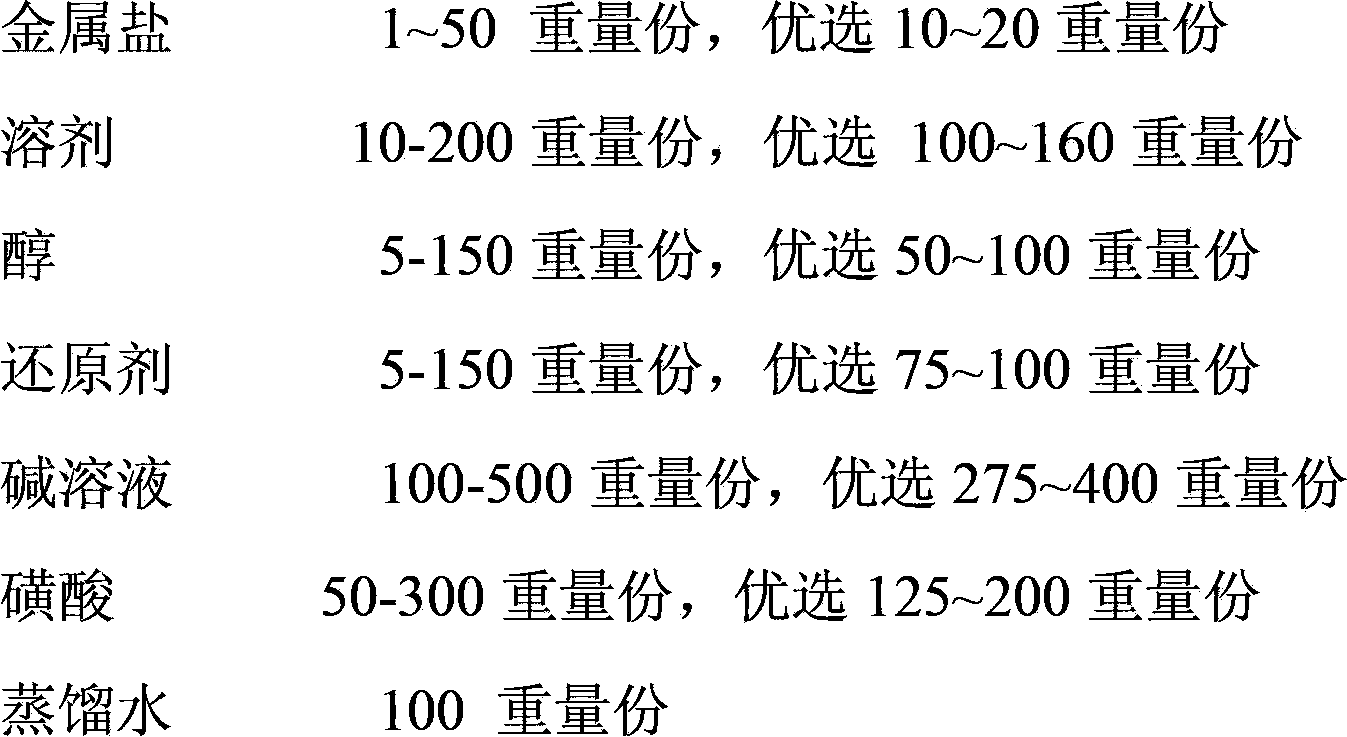

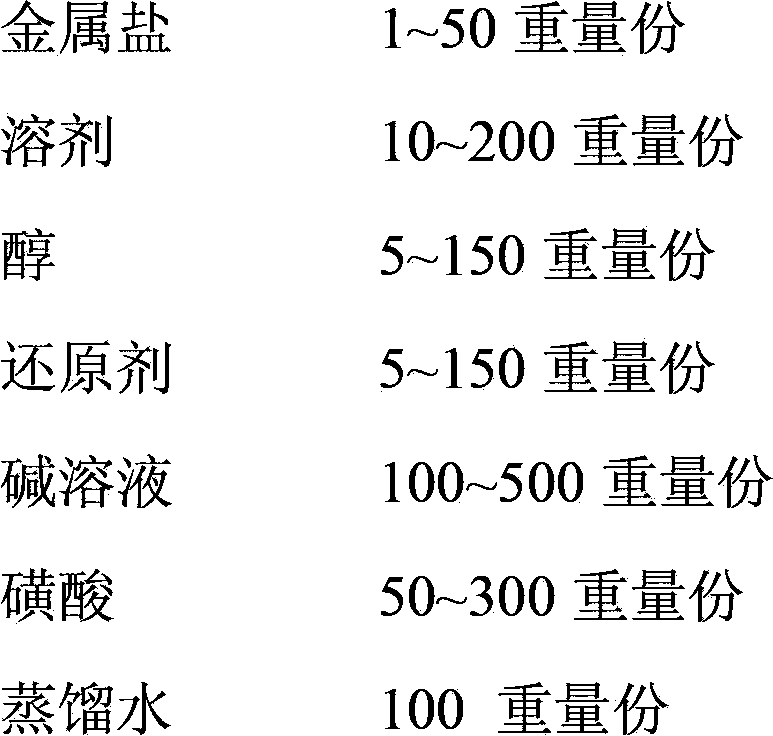

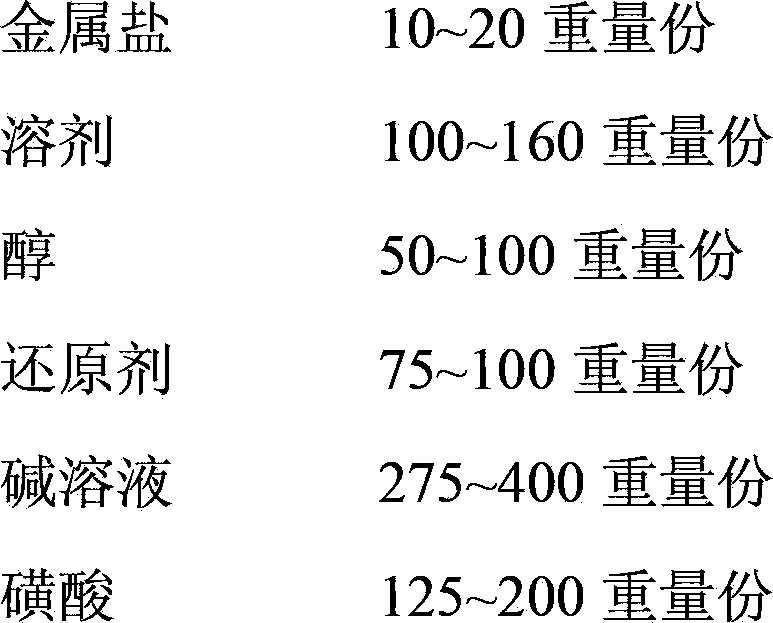

[0040] Nano-catalyzed viscosity reducer for hydrothermal cracking of heavy oil and preparation method thereof, comprising the following steps:

[0041]1) Selection of raw materials: iron salt: 2 parts by weight; solvent: 12 parts by weight; alcohol: 7 parts by weight; reducing agent: 6 parts by weight; alkali solution: 105 parts by weight; sulfonic acid: 55 parts by weight; distilled water: 100 parts by weight share. The iron salt is ferric nitrate, analytically pure, produced by Tianjin Jinhui Taiya Chemical Reagent Co., Ltd.; the alkaline solution is potassium hydroxide solution, with a concentration of 1mol / L, analytically pure, produced by Sinopharm Chemical Reagent Co., Ltd. ; Described solvent is n-heptane, analytically pure, produced by Sinopharm Chemical Reagent Co., Ltd.; described alcohol is n-butanol, analytically pure, produced by Beijing Yili Fine Chemicals Co., Ltd.; described reducing agent is boron Sodium hydride, analytically pure, produced by Kemiou Chemical...

Embodiment 2

[0045] Nano-catalyzed viscosity reducer for hydrothermal cracking of heavy oil and preparation method thereof, comprising the following steps:

[0046] 1) Selection of raw materials: cobalt salt: 15 parts by weight; solvent: 125 parts by weight; alcohol: 75 parts by weight; reducing agent: 82 parts by weight; alkaline solution: 300 parts by weight; sulfonic acid: 150 parts by weight; distilled water: 100 parts by weight share. The cobalt salt is cobalt sulfate, analytically pure, produced by Beijing Kangpu Huiwei Chemical Co., Ltd.; the alkali solution is sodium hydroxide solution, with a concentration of 2mol / L, analytically pure, produced by Sinopharm Chemical Reagent Co., Ltd.; The solvent is xylene, analytically pure, produced by Beijing Yili Fine Chemicals Co., Ltd.; the alcohol is n-amyl alcohol, analytically pure, produced by Beijing Yili Fine Chemicals Co., Ltd.; the reducing agent is hydration Hydrazine, analytically pure, produced by Kemiou Chemical Reagents; the su...

Embodiment 3

[0050] Nano-catalyzed viscosity reducer for hydrothermal cracking of heavy oil and preparation method thereof, comprising the following steps:

[0051] 1) Selection of raw materials: nickel salt: 24 parts by weight; solvent: 85 parts by weight; alcohol: 77 parts by weight; reducing agent: 79 parts by weight; alkali solution: 310 parts by weight; sulfonic acid: 181 parts by weight; distilled water: 100 parts by weight share. The nickel salt is nickel chloride, analytically pure, produced by Beijing Century Oriental Chemical Co., Ltd.; the alkali solution is sodium hydroxide solution, with a concentration of 3mol / L, analytically pure, produced by Sinopharm Chemical Reagent Co., Ltd.; The solvent described is toluene, produced by Kemiou Chemical Reagents; the alcohol described is n-amyl alcohol, analytically pure, produced by Beijing Yili Fine Chemicals Co., Ltd.; the reducing agent is potassium borohydride, analytically pure, produced by Kemiou Produced by European chemical rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com