Full spectrum LED light source module for LCD backlight

An LED light source and LED backlight technology, applied in the field of full-spectrum LED light source modules, can solve the problems of aging attenuation and inconsistent stability, affecting the visual effect of the display, increasing the thermal resistance from the chip to the light bar, etc. uniformity, improved stability and lifetime, reduced component and process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

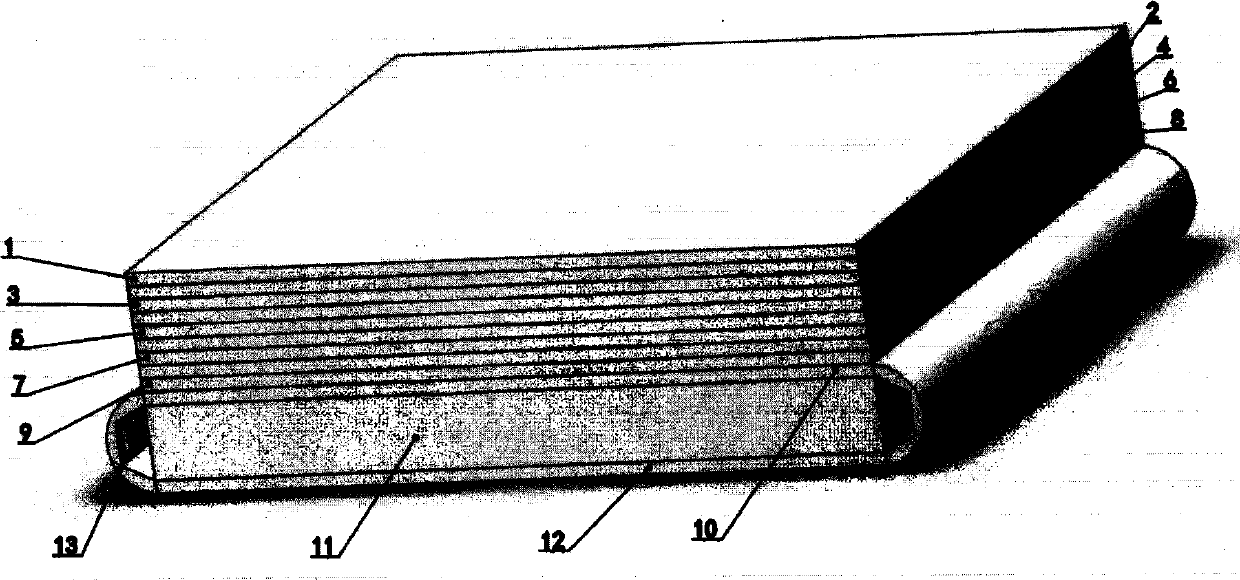

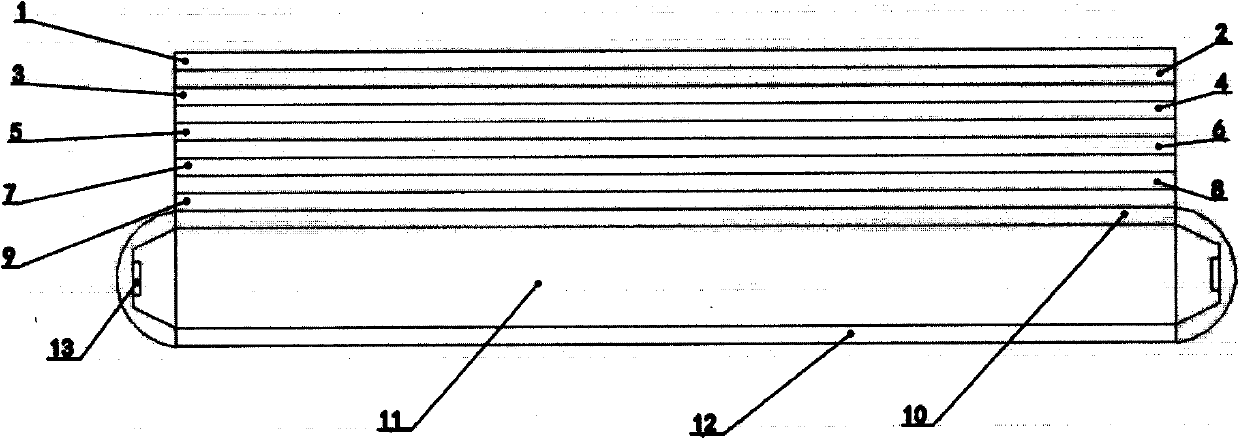

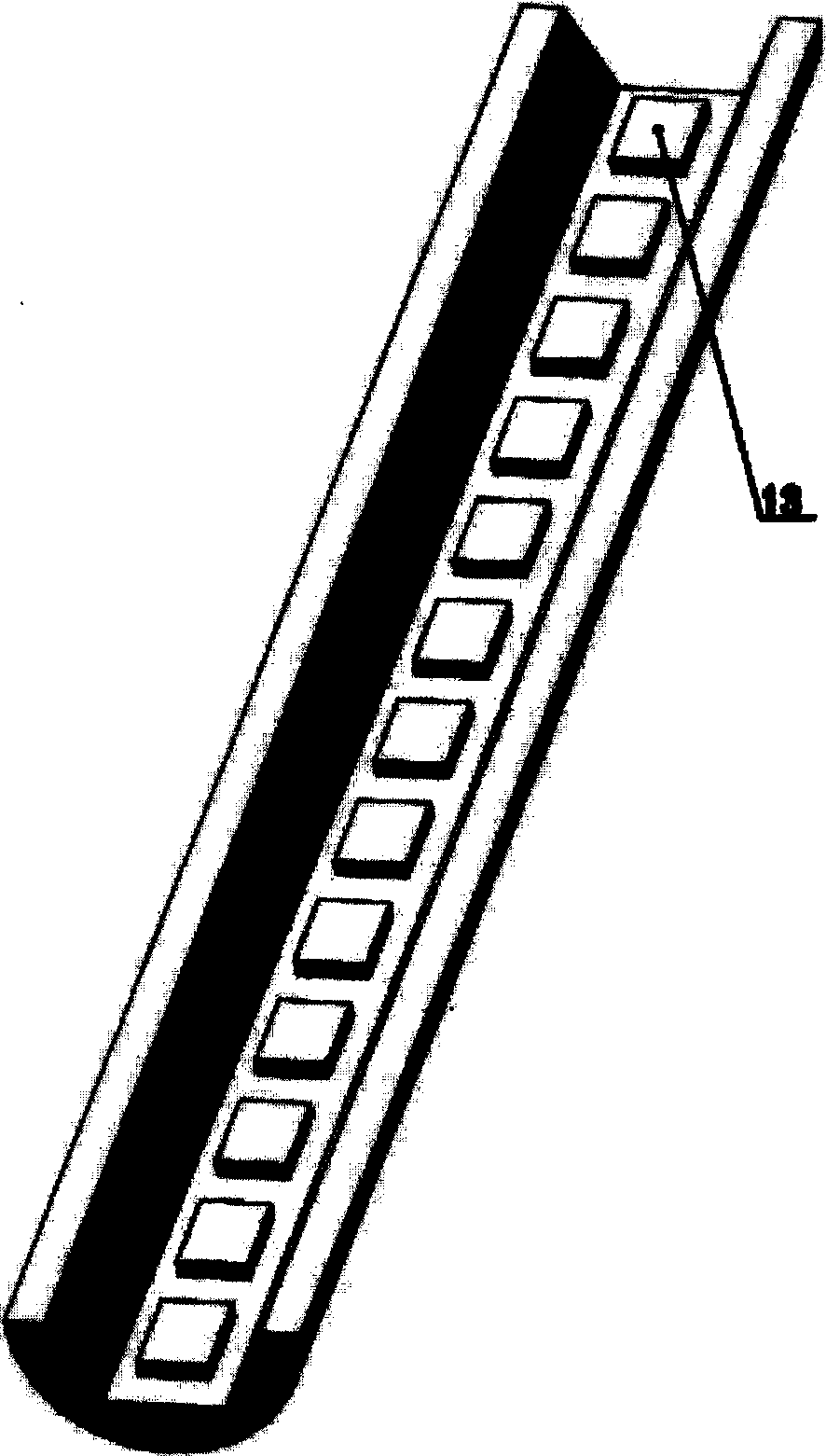

[0026] 1. Select the blue light chip (13) as the excitation light source, and fix it on the substrate with a die-bonding glue; 2. Select the full-spectrum phosphor powder (15) and the matrix material (14) of the zinc oxide system, and prepare them by hot pressing Phosphor powder light conversion plate (9); 3. The phosphor powder light conversion plate (9) is placed on the upper layer of the diffuser plate (10) away from the LED chip (13), to prepare a high stability, uniform color, high color saturation, A low-cost full-spectrum LED light source module; 4. An LCD device can be obtained by combining the full-spectrum LED light source module with an LCD panel.

Embodiment 2

[0028] 1. Select the ultraviolet light chip (13) as the excitation light source, and fix it on the substrate with a die-bonding glue; 2. Select the full-spectrum phosphor powder (15) and the base material (14) of the zinc oxide system, and use the method of hot pressing Prepare the phosphor powder light conversion plate (9); 3. The phosphor powder light conversion plate (9) is placed on the upper layer of the diffusion plate (10) in a way away from the LED chip (13), to prepare a high stability, uniform color, and high color saturation. 1. A low-cost full-spectrum LED light source module; 4. An LCD device can be obtained by combining the full-spectrum LED light source module with an LCD panel.

Embodiment 3

[0030] 1. Select the near-ultraviolet light chip (13) as the excitation light source, and fix it on the substrate with a die-bonding glue; 2. Select the full-spectrum phosphor powder (15) and the base material (14) of the zinc oxide system, and use hot-pressed The method prepares the phosphor powder light conversion plate (9); 3. The phosphor powder light conversion plate (9) is placed on the upper layer of the diffuser plate (10) in a way away from the LED chip (13), so as to prepare a high stability, uniform color, and color saturation A full-spectrum LED light source module with high cost and low cost; 4. An LCD device can be obtained by combining the full-spectrum LED light source module with an LCD panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com