Agricultural equipment parameter measurement and control system

A measurement and control system and equipment technology, applied in the field of agricultural measurement and control, can solve the problems of single function, difficult synchronization test, single measurement and control object, etc., and achieve the effect of broad application prospects, simple and reliable debugging, accurate and fast signal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 Assembly embodiment of the present invention

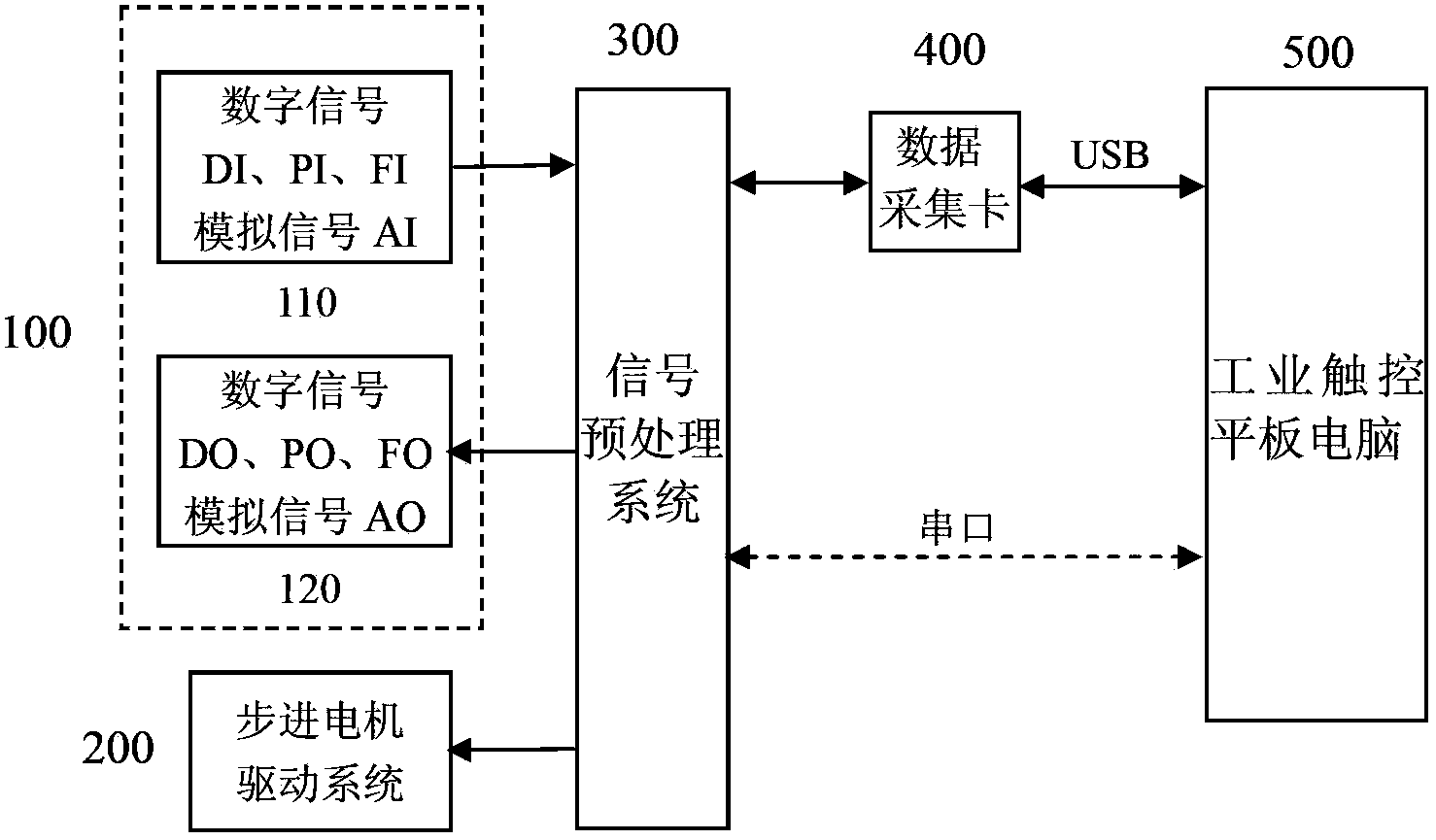

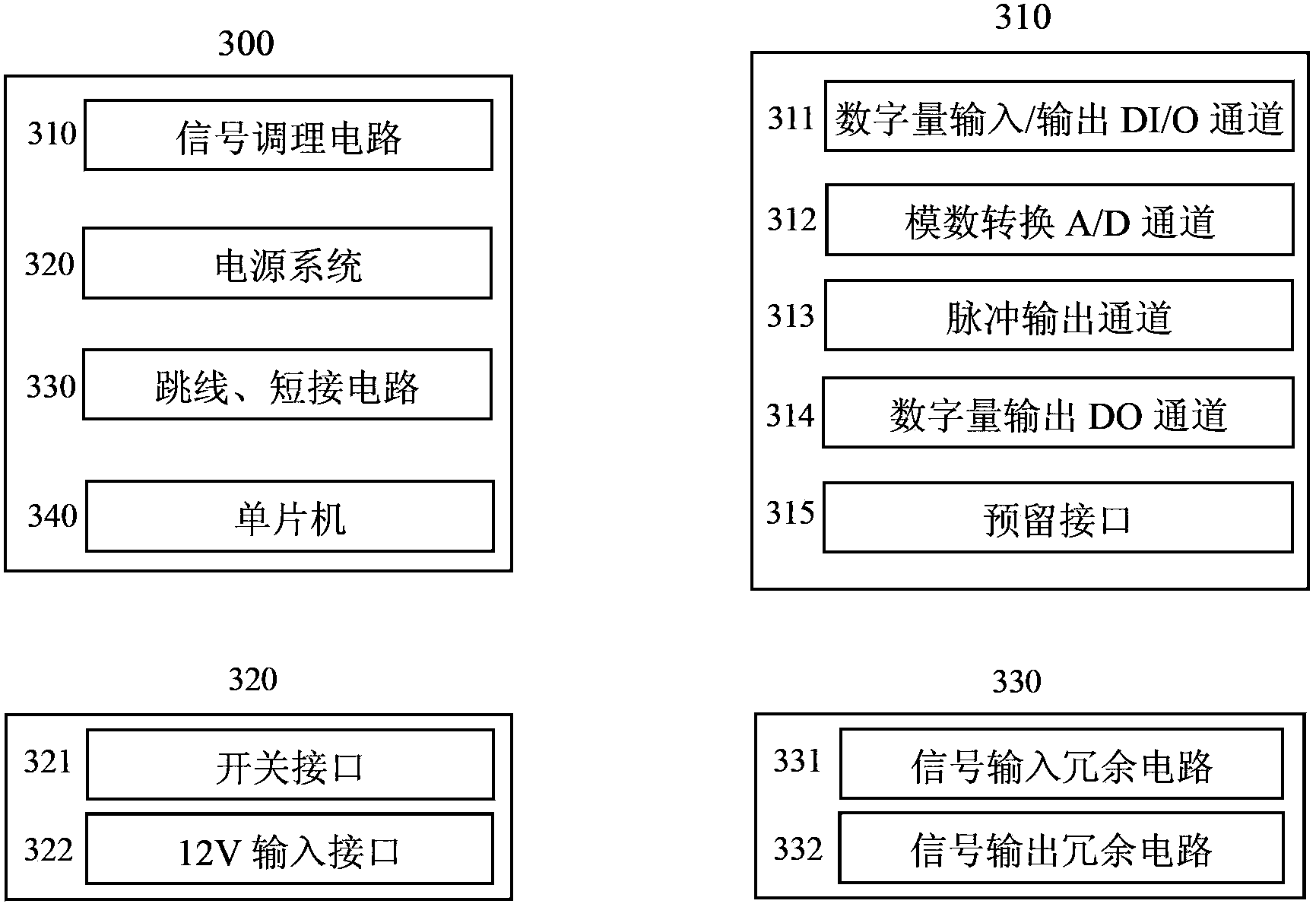

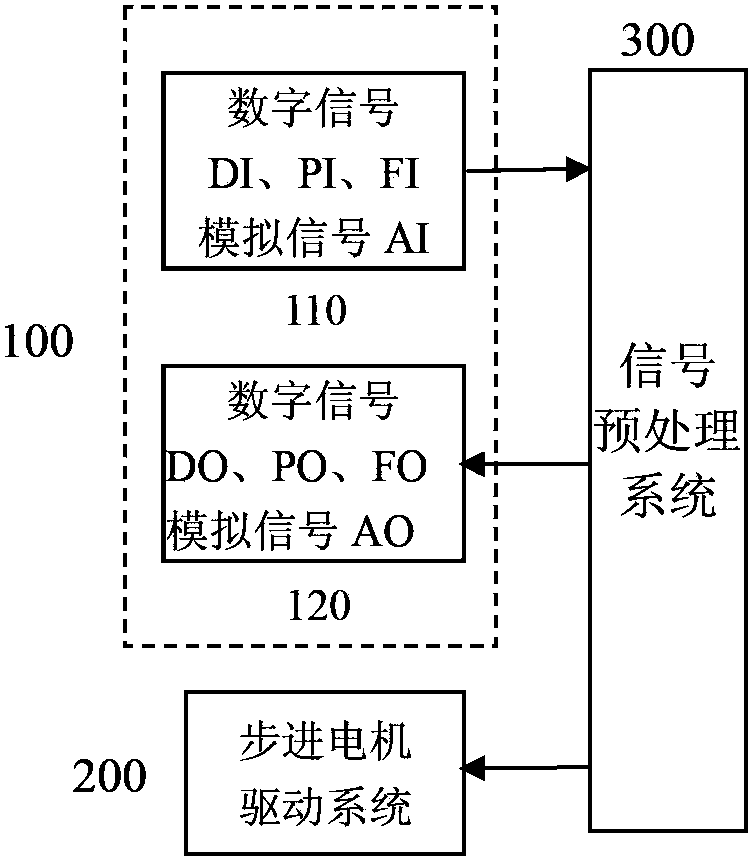

[0048] A parameter measurement and control system for agricultural equipment, including a process channel module (100), a stepping motor drive system (200), a signal preprocessing system (300), a data acquisition card (400), and an industrial touch panel computer (500);

[0049] The process channel module (100), the signal preprocessing system (300) and the industrial touch panel computer (500) are connected in sequence;

[0050] The process channel module (100), the data acquisition card (400) and the industrial touch panel computer (500) are connected in sequence;

[0051] The signal preprocessing system (300) is connected to the data acquisition card (400) through a cable, and then connected to the industrial touch panel computer (500) to build a direct measurement and control system;

[0052] The signal preprocessing system (300) constructs a direct measurement and control system through a single-chip micr...

Embodiment 2 application Embodiment 1

[0066] Refer below Figure 6 Introduce the application example 1 of the present invention - the application of visual navigation of agricultural vehicles (001):

[0067] During the field work of agricultural vehicles, there are always working areas and non-working areas. Use this measurement and control system and the industrial camera configured to detect the boundary line of the working area and the non-working area in real time, and then obtain the heading deviation and navigation position deviation. Through the constructed navigation control The system realizes the automatic steering of the steering wheel, and finally achieves the purpose of automatic driving of agricultural vehicles along the boundary line, reduces the labor intensity of the operation, and improves the quality of the operation.

[0068] Using the process channel module (100) of the construction system of the present invention, the angle sensor (111) installed on the steering wheel shaft of the agricultura...

Embodiment 3 application Embodiment 2

[0075] Refer below Figure 8 Introduce application example 2 of the present invention--concentrated pneumatic precision seed metering device (002) seeding rate control:

[0076] Concentrated pneumatic precision seed metering device (developed by the Engineering College of Huazhong Agricultural University, patent number 2009100610887, authorized date January 26, 2011) relies on the rotation of the seeding disc to allow the rapeseed to obtain sufficient centrifugal force and then reach the position of the hole for seeding. , The amount of seeding increases with the increase of the speed. This application is to use the measurement and control system to realize the control of the speed of the centrifugal seeding disc through real-time detection of the speed of the rapeseed live broadcast machine, and then realize the control of the seeding amount and achieve the consistency of seeding.

[0077] Utilize the process channel module (100) of the system designed by the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com